A centrifugal separation drum machine

A technology of centrifugal separation and drum machine, which is applied in the direction of centrifuges and centrifuges with rotating drums, etc. It can solve the problems of accurately adjusting the amount of output, synchronous rotation, and small centrifuge processing capacity, and achieves easy replacement. Damaged parts, easy outlet flow, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

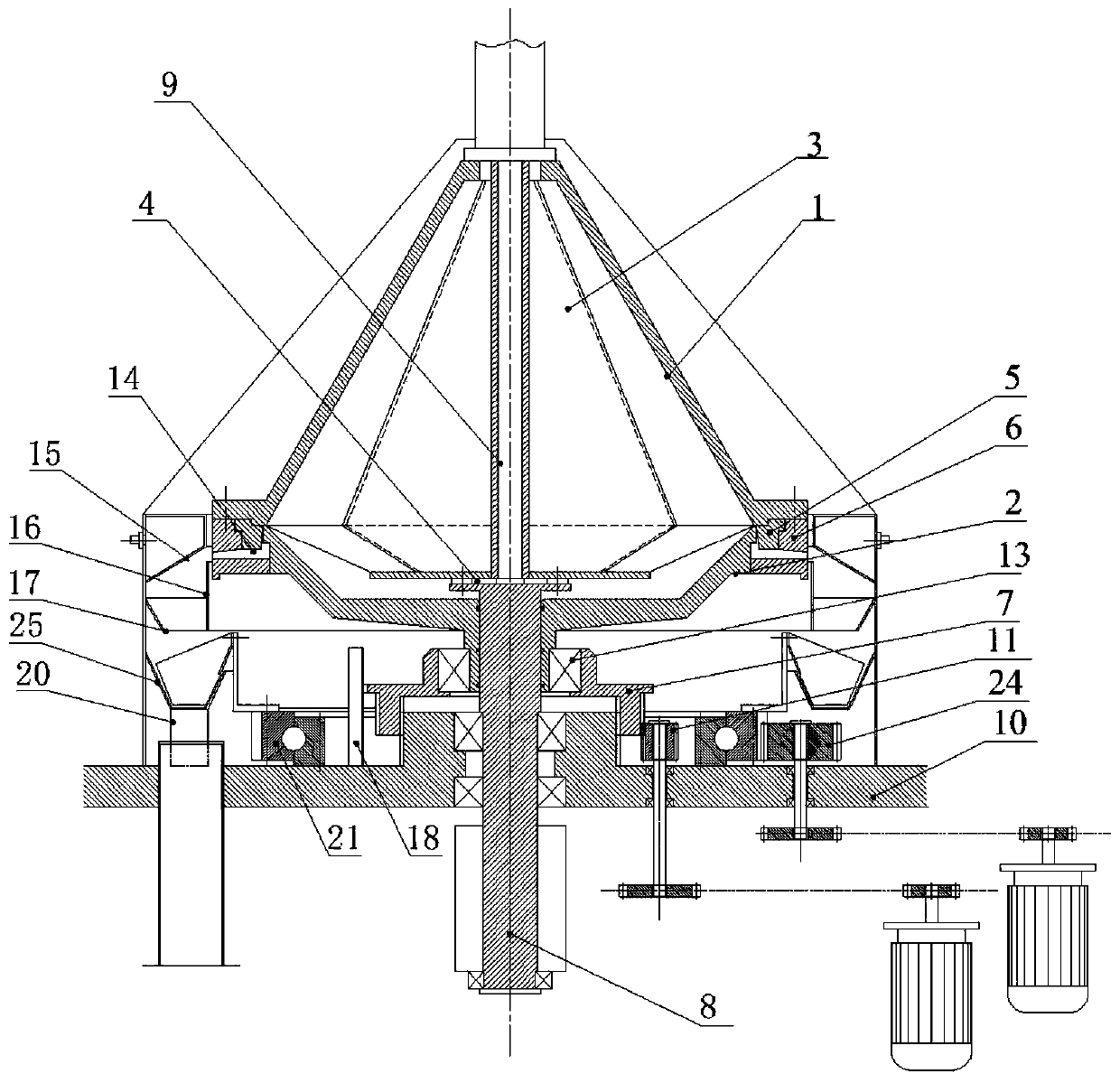

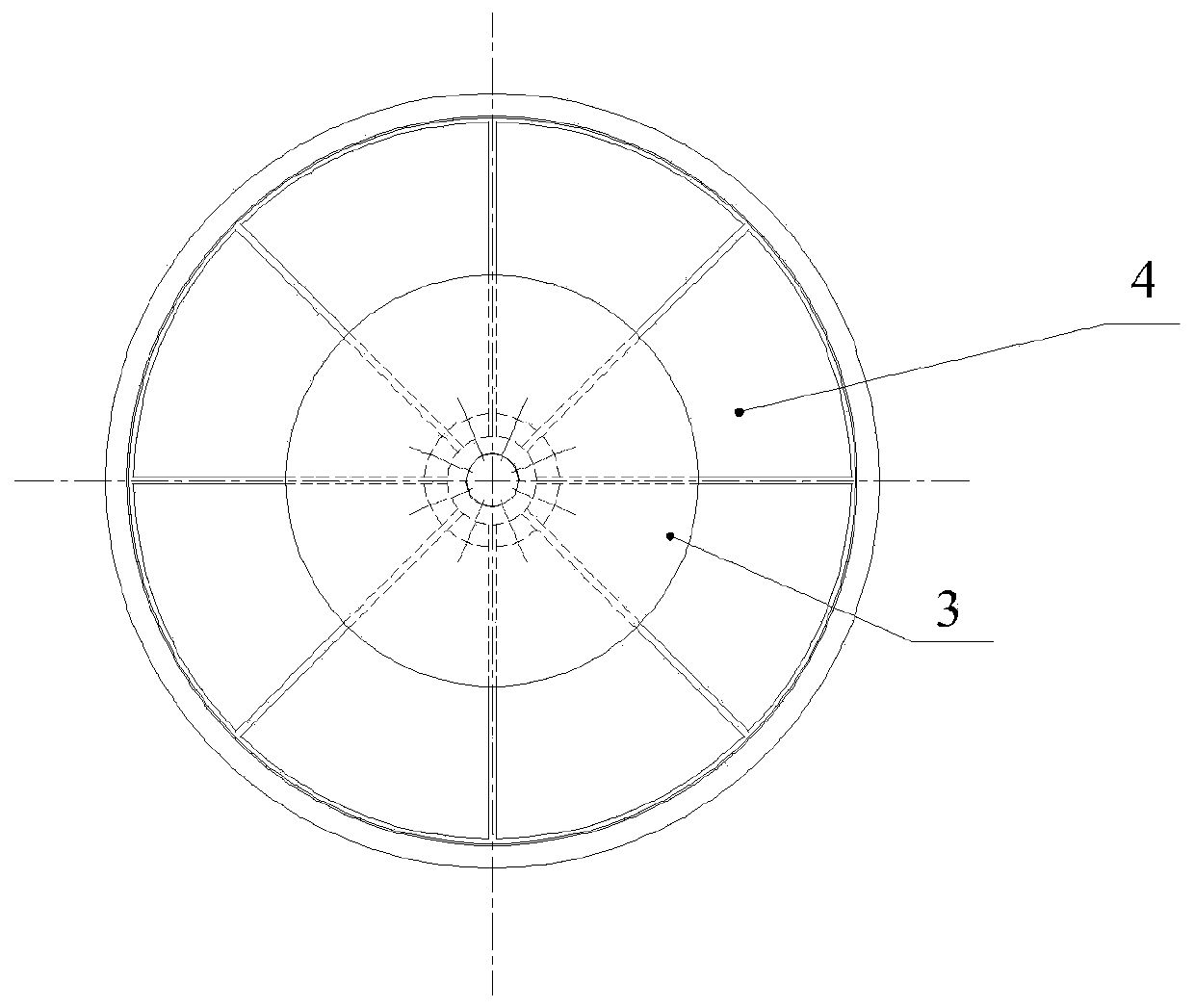

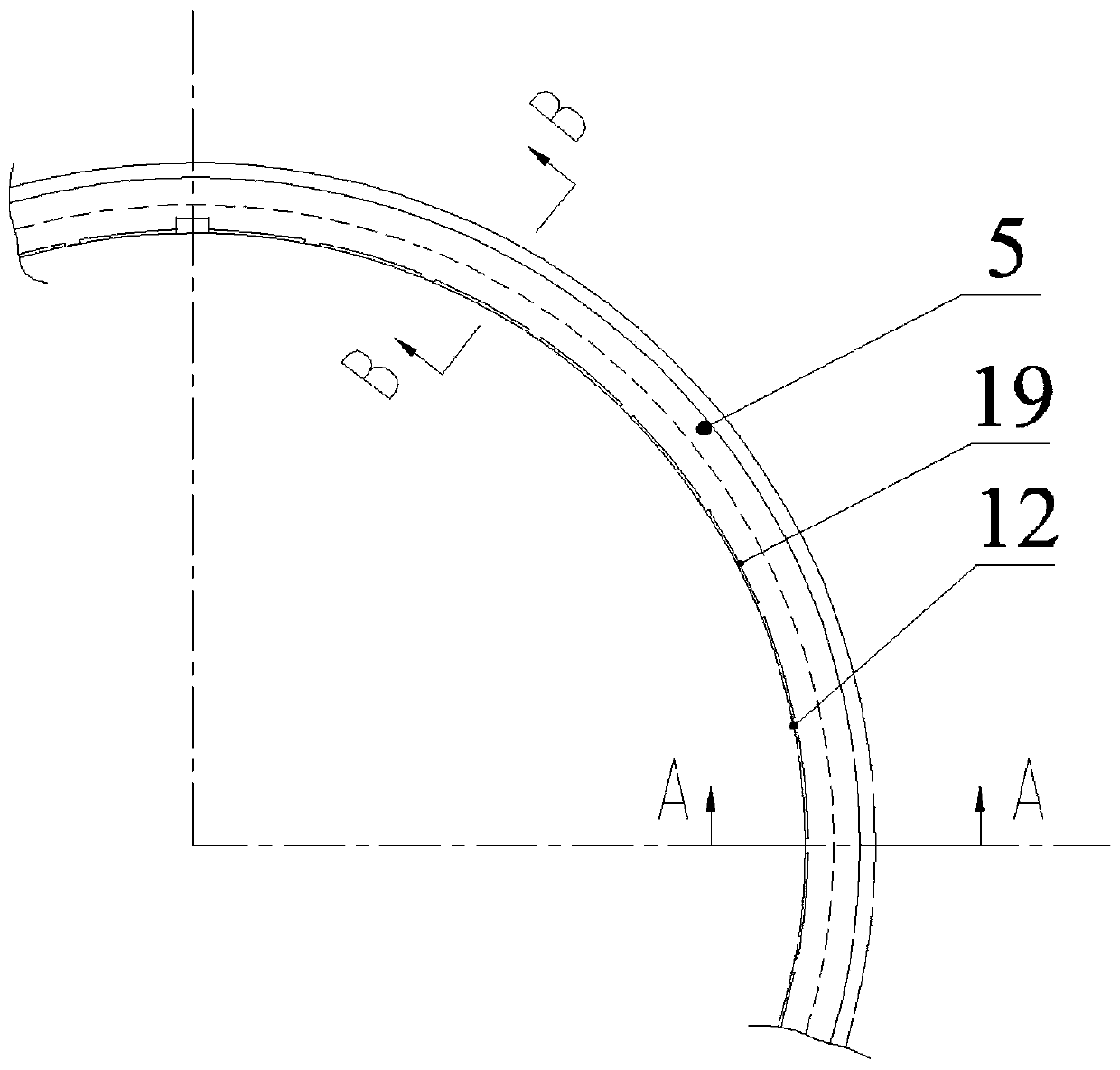

[0035] Such as figure 1 and figure 2 As shown, the centrifugal separation drum machine of the present invention includes an upper drum 1, a lower drum 2, a slag discharge retaining ring 5, a positioning ring 6, a drive shaft 8 and a rotating slag scraping system; the upper drum 1 The interior is divided into several separation chambers 3 in the radial direction, and the separation chamber 3 is provided with a liquid outlet at the top of the upper drum 1, and the upper drum 1 is provided with a feed pipe 9 inside, and the feed pipe 9 Located at the axial position of the upper drum 1, one end of the feed pipe 9 is connected to the top of the upper drum 1, and the other end of the feed pipe 9 is installed with the feed distribution plate 4, and the feed pipe 9 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com