A kind of motor vehicle number plate reflective film preprinting machine

A technology for reflective film and motor vehicles, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of poor ink layer uniformity, low printing efficiency of reflective film ink, etc., to improve uniformity, The effect of avoiding bonding and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

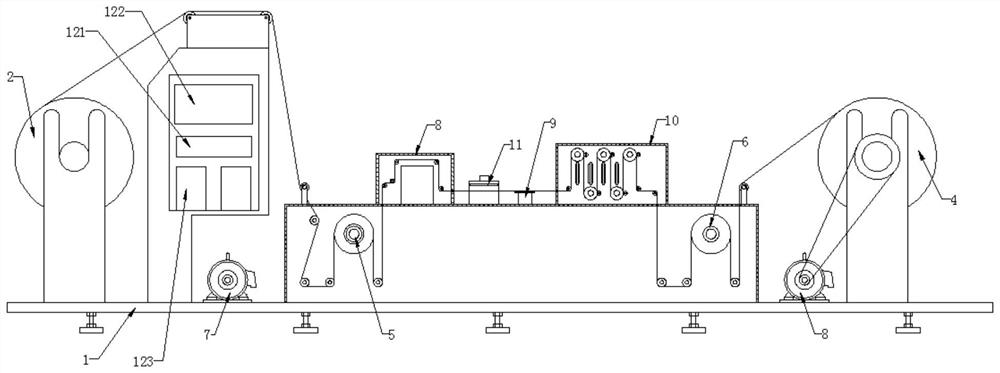

[0039] This embodiment, as the basic embodiment of the present invention, discloses a motor vehicle number plate reflective film pre-printing machine, the specific structure is as follows figure 1As shown, including a frame 1, the left and right ends of the frame 1 are rotated by rolling bearings to be provided with a discharge roller 2 and a material collection roller 3, and at the same time, a material receiving motor 4 is also provided at the rear of the frame 1, and the material receiving motor 4 It is connected to the receiving roller 3 through a synchronous belt; at the same time, between the discharging roller 2 and the receiving roller 3, there are also a driving feeding roller 5 and a driven feeding roller 6, and between the driving feeding roller 5 and the driven feeding roller 6 The power is connected by the synchronous belt, and the frame 1 on one side of the active feed roller 5 is fixedly provided with a feed motor 7, and the feed motor 7 is connected by the power...

Embodiment approach 2

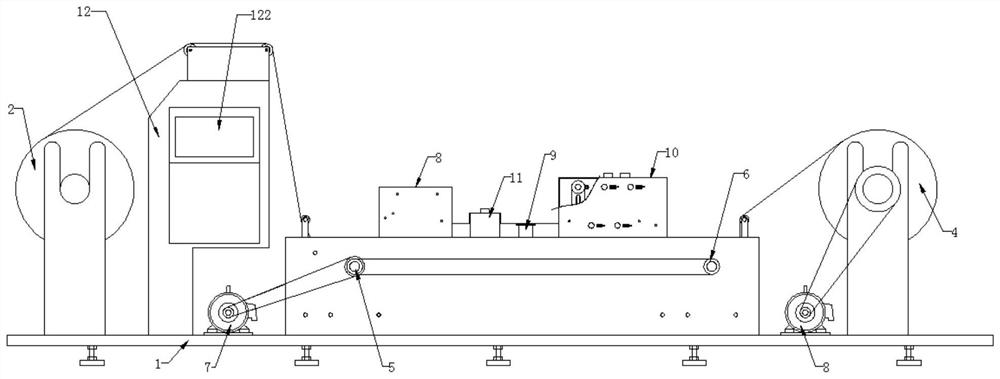

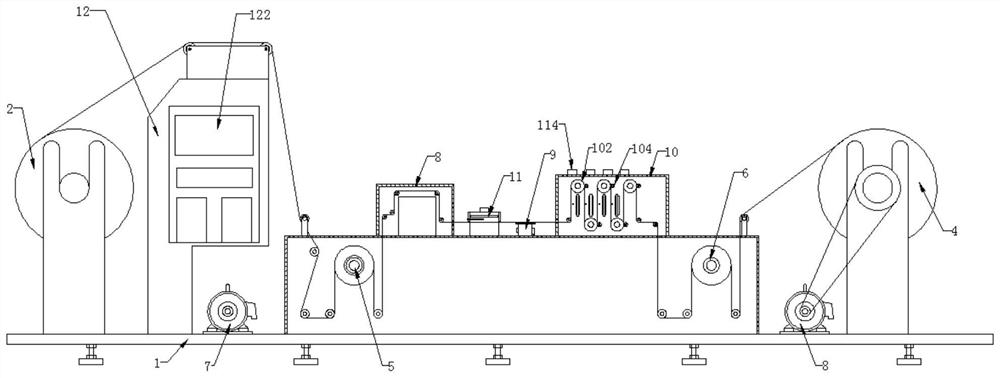

[0045] This embodiment, as a preferred embodiment of the present invention, discloses a motor vehicle license plate reflective film pre-printing machine on the basis of Embodiment 1. The specific structure is as follows: Figure 2 to Figure 10 As shown, it includes a frame 1, the two sides of the frame 1 are provided with the left and right ends and are provided with a discharge roller 2 and a collection roller 3 through rolling bearing rotation, and there is also a roller between the discharge roller 2 and the collection roller 3 The active feed roller 5 and the driven feed roller 6 are provided with an ink roll printing device 9, a first drying device 11, an ink scraping device 9 and a second drying device in sequence between the active feeding roller 5 and the driven feed roller 6. Drying device 10, the first drying device 11 includes a door-shaped bracket 111 fixed on the frame 1, the inlet and outlet of the left and right sides of the door-shaped bracket 111 are fixedly pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com