Punching device of lead-acid storage battery casing

The technology of a lead-acid battery and a punching device is applied in the field of a lead-acid battery shell punching device, which can solve problems such as low punching efficiency, increased production costs, and reduced production efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

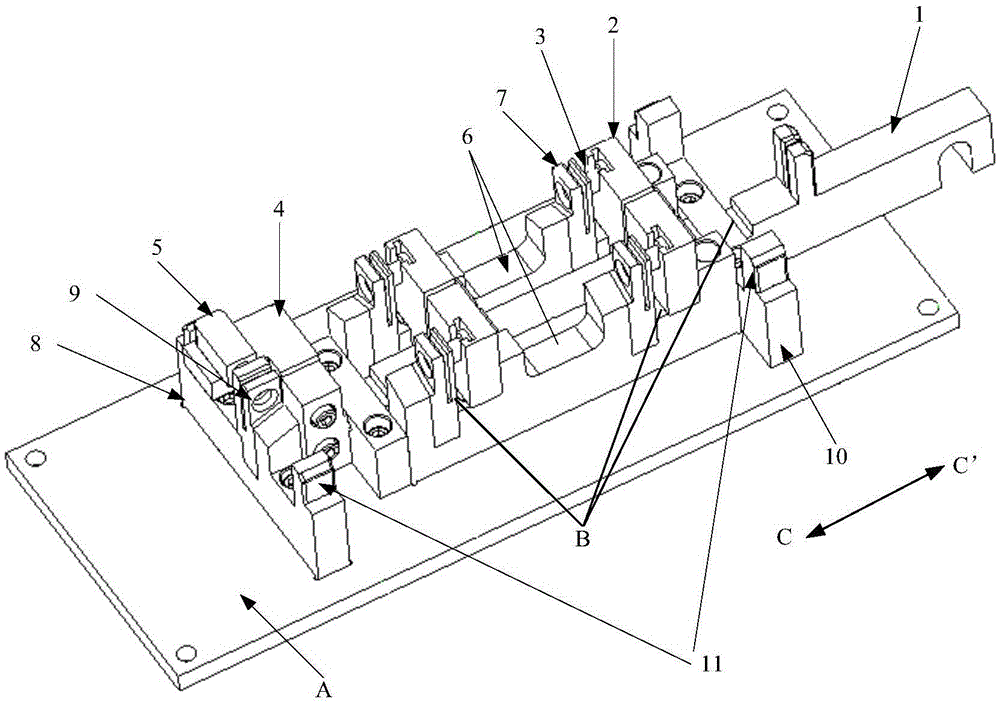

[0024] Please refer to Figure 1A , the embodiment of the present application provides a lead-acid battery case punching device, including:

[0025] Movable push rod 1.

[0026] Wherein, the push rod 1 can be connected with an air source such as a cylinder to push the push rod 1 .

[0027] At least one punch seat 2 fixedly installed on the push rod 1, on which a punch 3 for punching holes is fixedly installed. The direction of the punching end 3A of the punch 3 is consistent with the moving direction of the push rod 1 .

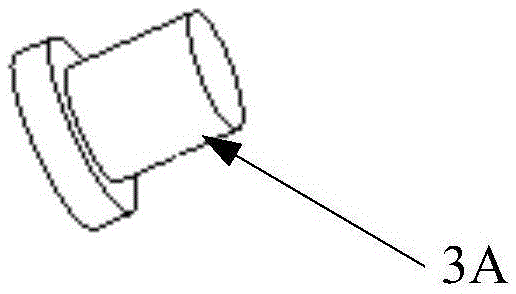

[0028] like Figure 1B Shown is a schematic structural view of the punch 3 .

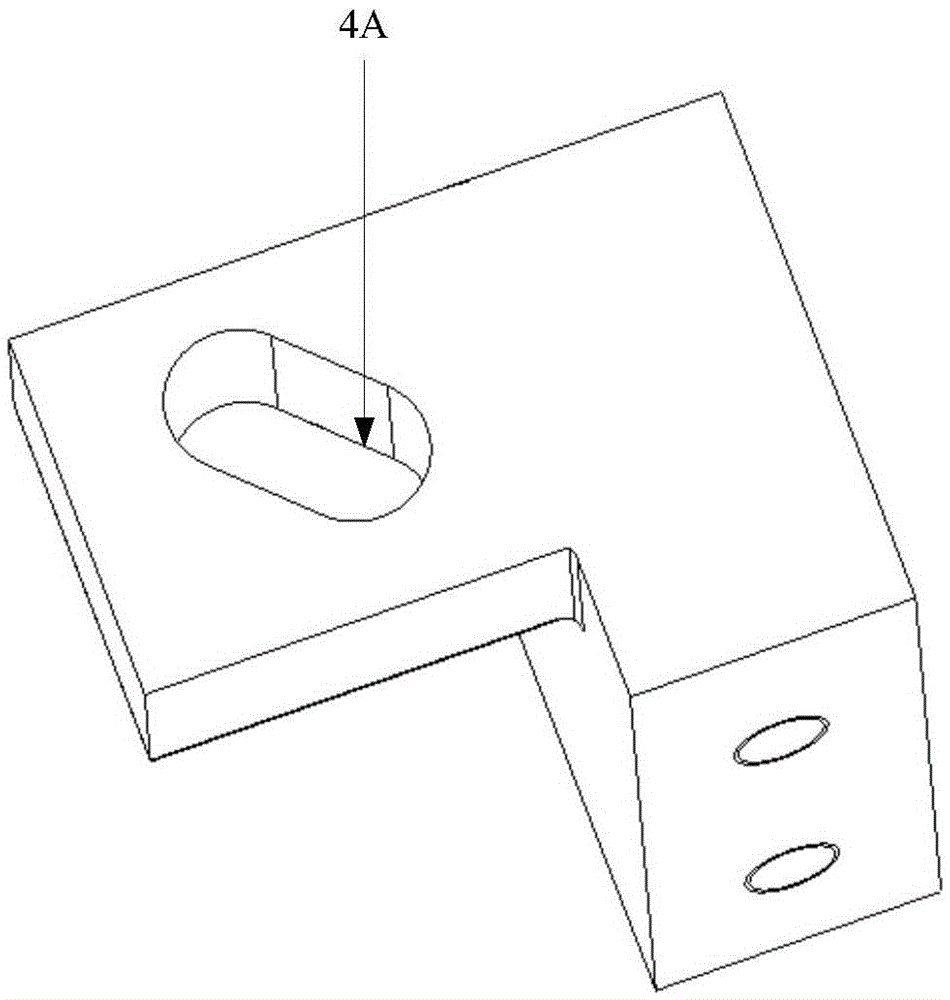

[0029] like Figure 1C , also includes a connecting rod 4 fixedly installed on the push rod 1, and the connecting rod 4 is provided with an oblique groove 4A.

[0030] Offset punching head 5, such as Figure 1D Shown is a schematic diagram of the structure of the offset punching head 5, the installation shaft 5A at the lower end of the offset punching head 5 is installed insi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap