Garbage bins suitable for robotic work

A technology of trash can and manipulator, applied in the field of trash can, can solve the problems of unstable position, inaccessible trash can, and the clamping force of manipulator cannot be too large, so as to prevent random placement and accidental dumping, beautify the city, and facilitate the The effect of manipulator work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

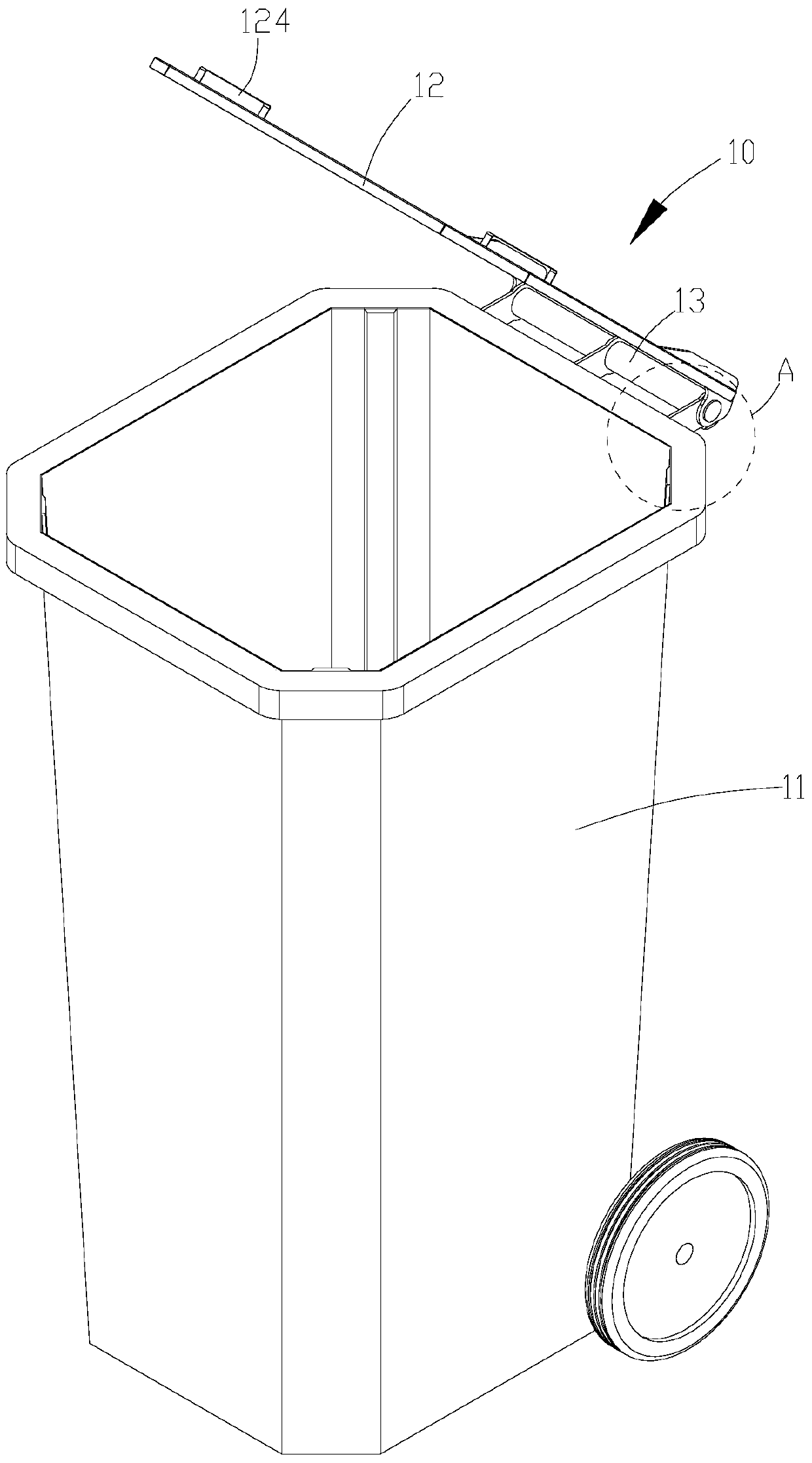

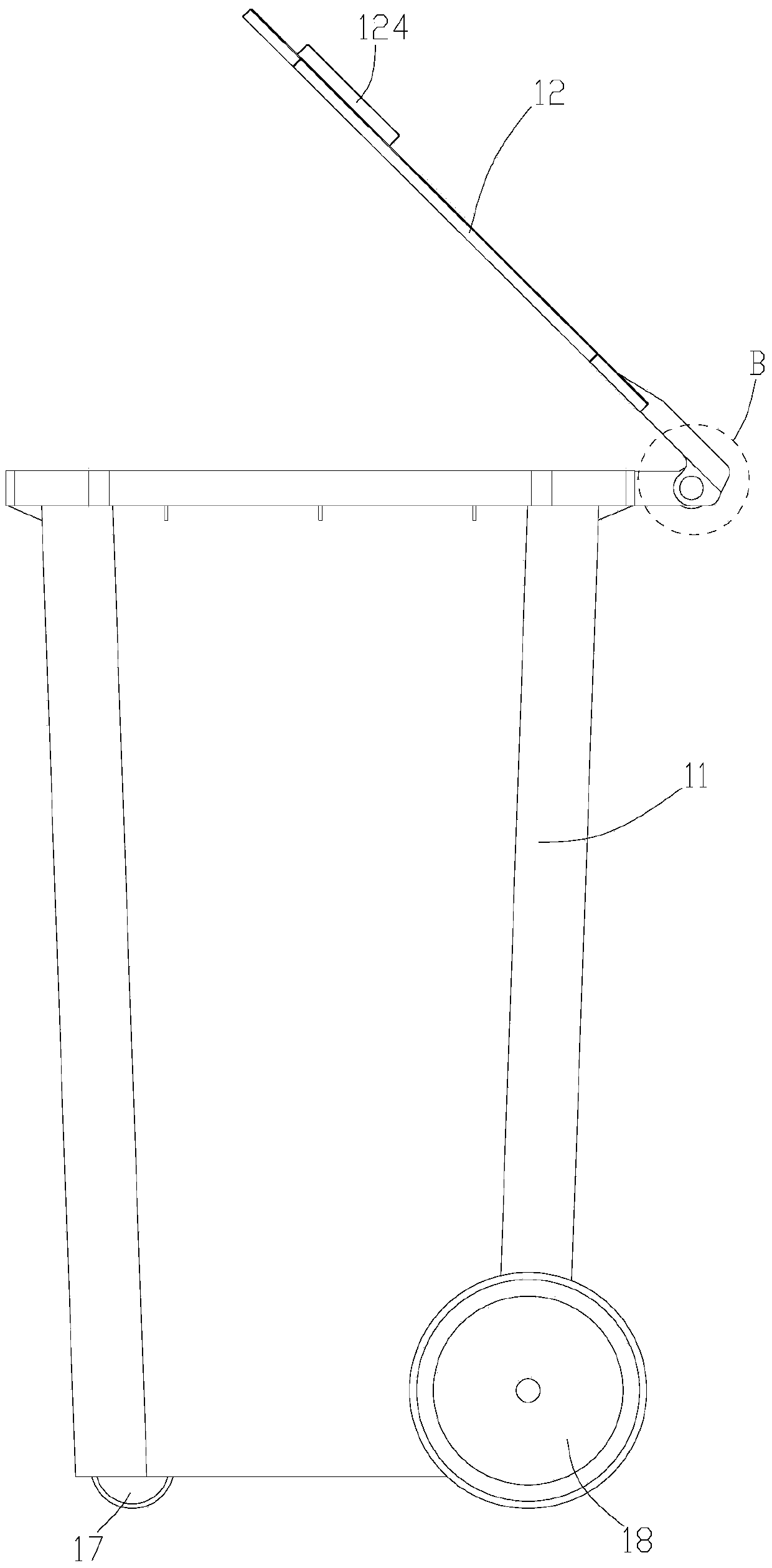

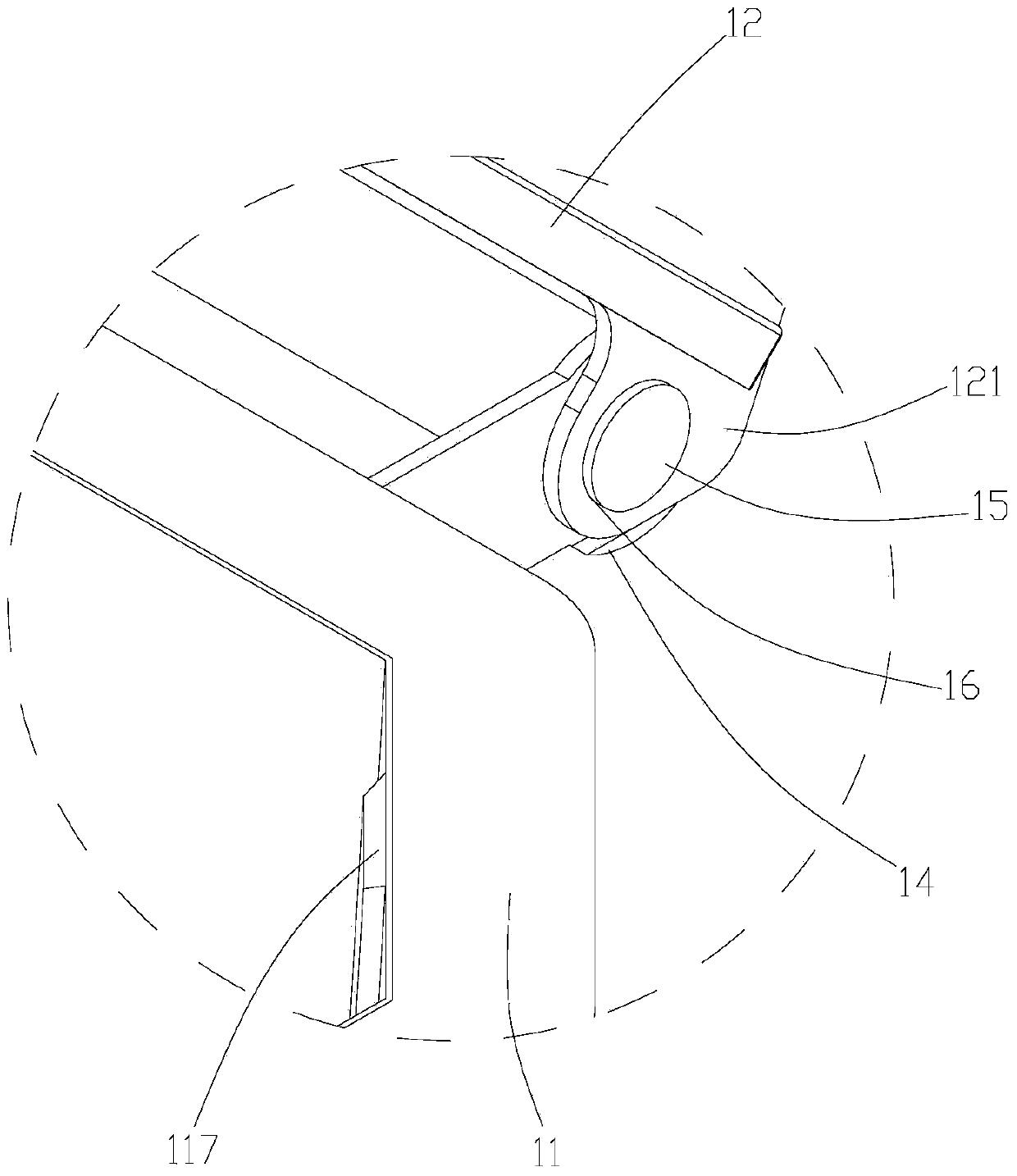

[0024] The invention provides a trash can suitable for manipulator operation. Such as Figure 1 to Figure 5 As shown, in one embodiment of the present invention, the trash can 10 suitable for manipulator operation includes a bucket body 11 and a bucket cover 12, the top rear side of the bucket body 11 is provided with a push handle 13, and the rear side of the bucket cover 12 is It is rotatably connected with the push handle 13, and the push handle 13 is provided with a limit mechanism to limit the maximum opening angle θ of the barrel lid 12 within 90°. Wherein, the maximum opening angle θ of the bung 12 refers to the angle between the closed position of the bung 12 and the maximum opening position of the bung 12 (such as Figure 4 shown).

[0025] In the trash can 10 suitable for manipulator oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com