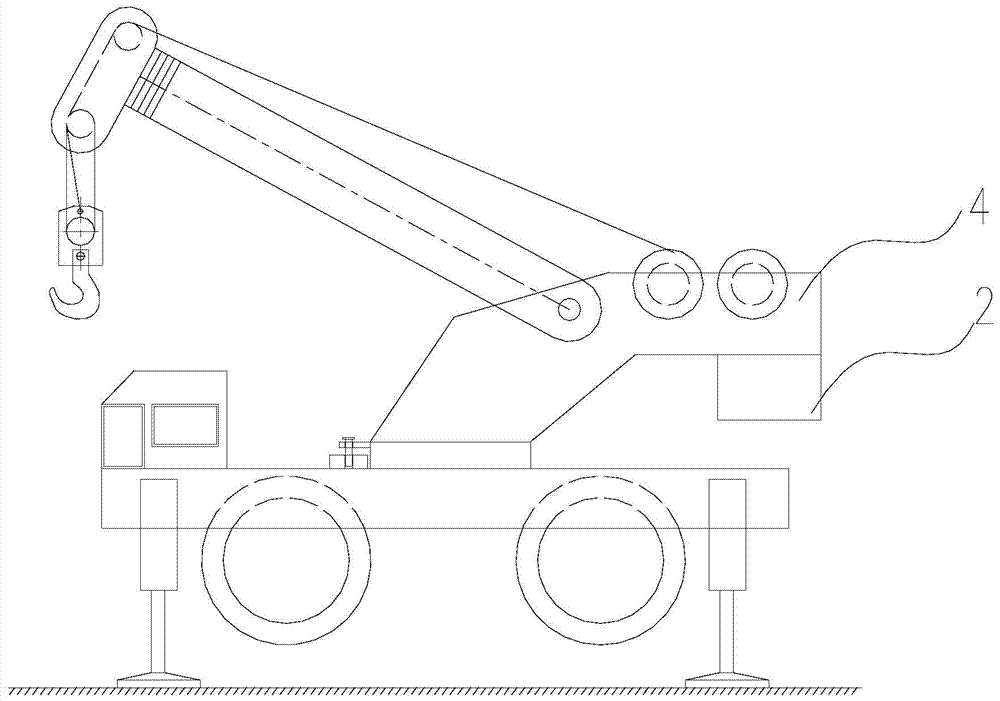

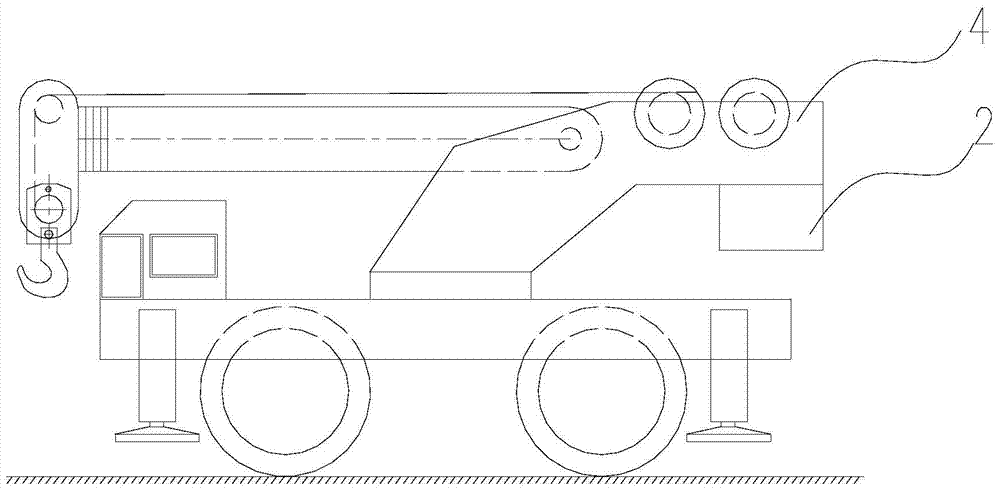

Cranes and their counterweight systems

A technology for cranes and auxiliary counterweights, applied to cranes, etc., can solve the problems of reducing work efficiency, increasing crane use costs, and cumbersome disassembly and assembly processes, and achieves the effects of improving work efficiency, ensuring lifting performance, and facilitating disassembly and assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a counterweight system of a crane, which has a simpler disassembly process. Another core of the present invention is to provide a crane including the above-mentioned counterweight system, which has a simpler disassembly process and reduces operating costs.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

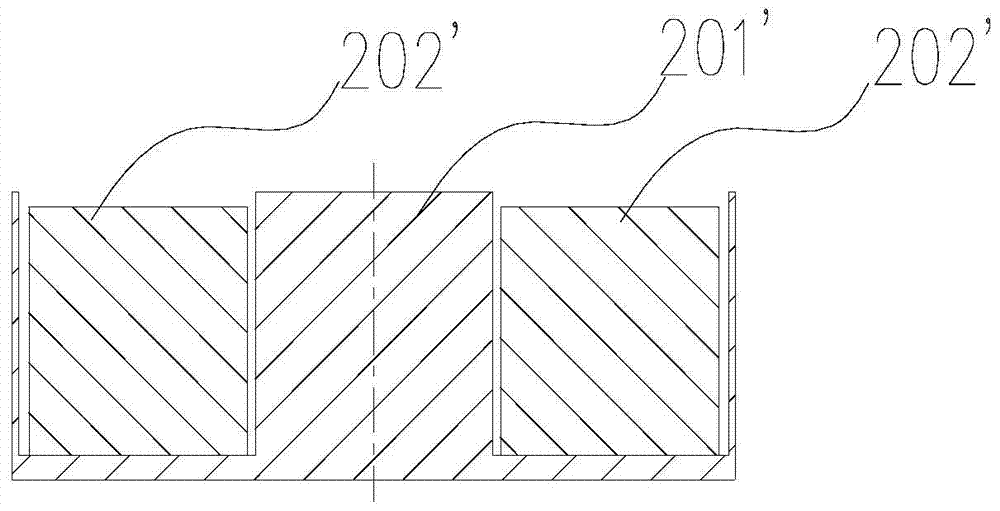

[0027] Please refer to Figure 4 to Figure 6 , Figure 4 It is a schematic front view of a specific embodiment of the counterweight system provided by the present invention; Figure 5 It is a schematic side view of a specific embodiment of the counterweight system provided by the present invention; Image 6 It is a partially enlarged view of the self-detachable power assembly in a specific embodiment of the counterweight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com