A cloth rolling mill with hydraulically adjusted rolls

A roll and cloth technology, which is applied in the field of textile printing and dyeing equipment, can solve the problems affecting the uniformity of force on the cloth and the effect of rolling, and achieve the effects of uniform force, improved rolling effect, and compensation for deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

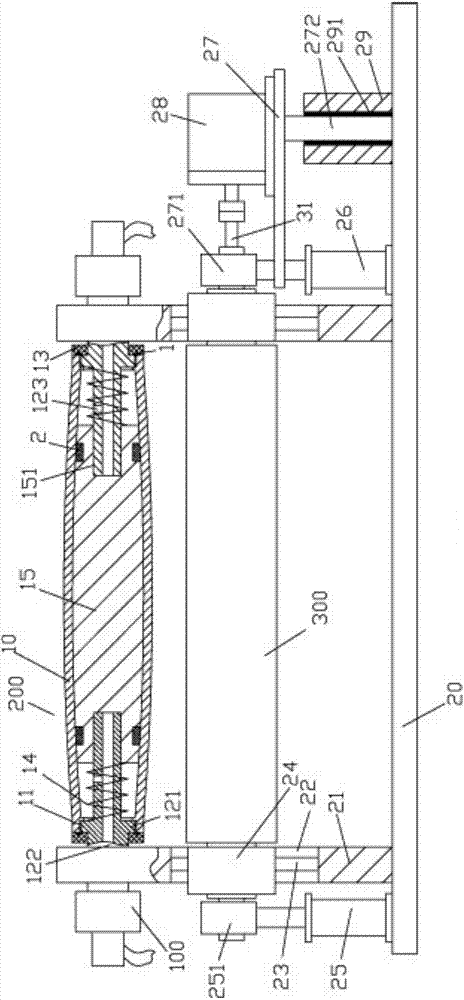

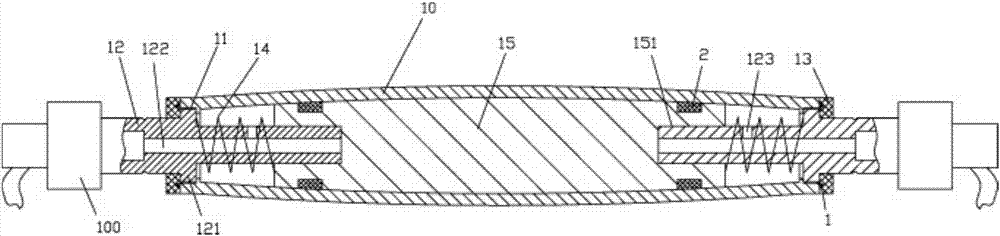

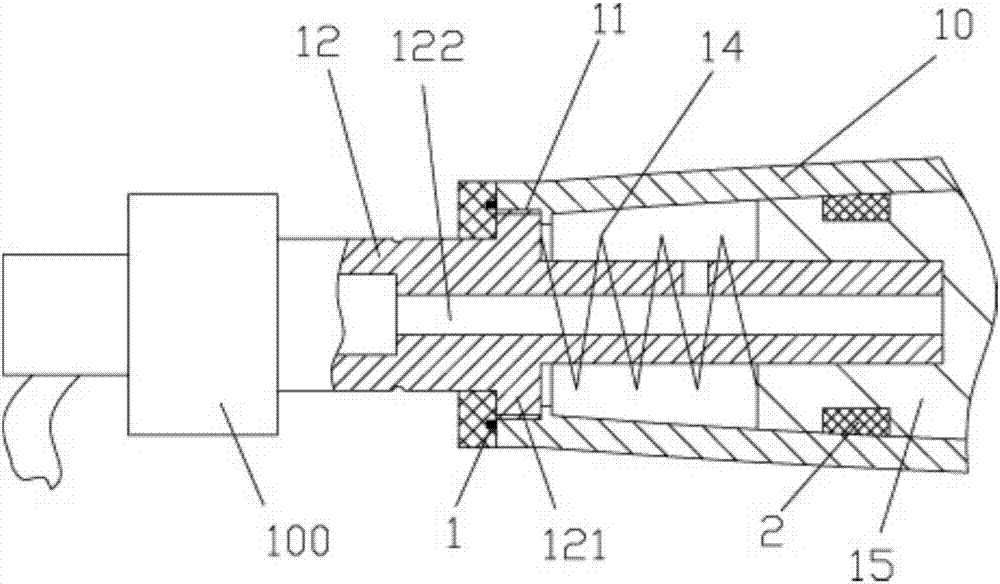

[0021] Examples, see e.g. Figure 1 to Figure 4 As shown, a cloth rolling mill with hydraulically adjusted rolls includes a roll 200 and a horizontal roll 300, the two ends of the roll 200 are hinged at the upper part of the two vertical support plates 21 of the frame 20, and the two vertical supports The bottom of the plate 21 has a moving through groove 22, and the two inner side walls of the moving through groove 22 have position-limiting protruding strips 23. In the vertical groove 241 that has on the side wall of block 24, the two ends of horizontal roller 300 are hinged on the corresponding mobile block 24, and left push oil cylinder 25 and right push oil cylinder 26 are fixed on the bottom plate of frame 20, left pushes The end of the push rod of the oil cylinder 25 is fixed with a connecting part 251, and the connecting part 251 is hinged at the left end of the horizontal roller 300. The push rod of the right push oil cylinder 26 is fixed with an adjusting plate 27, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com