Roller for cloth rolling mill

A rolling mill and cloth technology, which is applied in the field of textile printing and dyeing equipment, can solve the problems of affecting the rolling effect and the uniformity of the force on the cloth, and achieve the effect of improving the rolling effect and the uniformity of the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

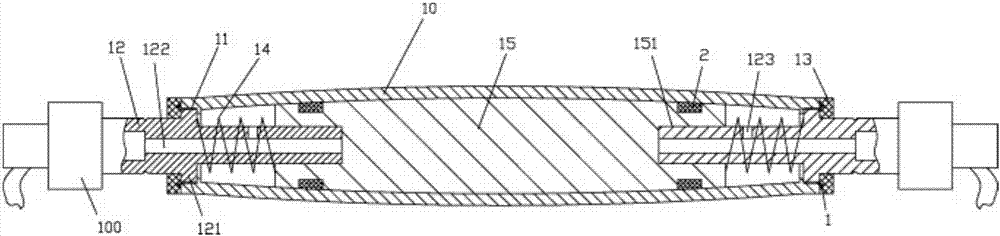

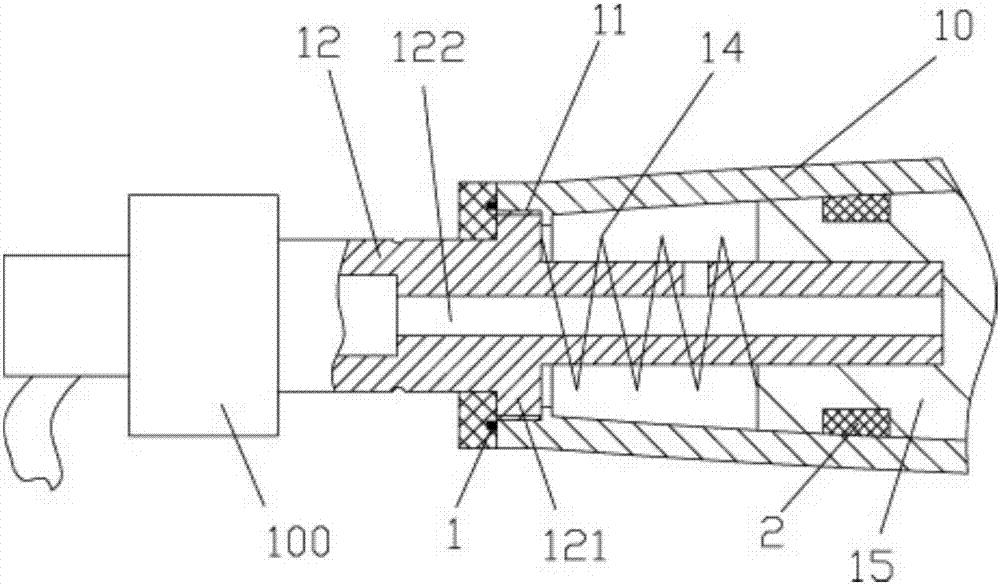

[0017] Examples, see e.g. Figure 1 to Figure 2 As shown, a roll for a cloth rolling mill includes a rubber outer roll sleeve 10, the diameter of the outer wall of the rubber outer roll sleeve 10 is that the diameter of the outer wall of the middle part gradually decreases toward the two ends of the rubber outer roll sleeve 10, and the two ends of the rubber outer roll sleeve 10 The inner wall of the end has a spline groove 11, and the middle parts of the two connecting shafts 12 extend into the rubber outer roller sleeve 10. The outer wall of the middle part of the connecting shaft 12 has a spline tooth part 121 extending radially outward, and the spline tooth part 121 is inserted into the spline. In the keyway 11, the connecting shaft 12 is inserted into the end connecting cover 13, and the end connecting cover 13 is fixedly connected to the end surface of the rubber outer roller sleeve 10 by bolts, and the outer end of the connecting shaft 12 is fixed with a rotary joint 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com