A method of strip rolling

A strip and stand technology, applied in the field of strip rolling, can solve the problems of not meeting customer needs, poor strip quality, low output, etc., to reduce energy consumption, reduce rolling power, and improve quality and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In an embodiment of the present invention, a strip rolling method is disclosed.

[0015] This method is specifically applied to the strip rolling model, which involves the optimization of the secondary setting tension of high-strength steel; the optimization of the rolling strategy of the secondary model of high-strength steel; the technology of automatic roll gap lifting for high-strength steel and thin gauge; force setting.

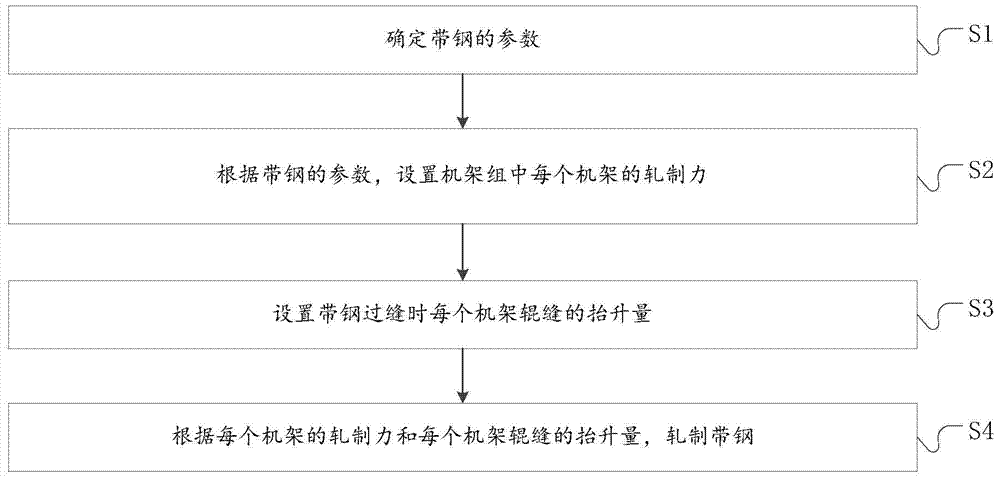

[0016] Please see figure 1 , in the specific implementation process, the flow process of the strip rolling method is as follows:

[0017] S1, determine the parameters of the strip.

[0018] Specifically, the strip steel parameters include many kinds, such as strip steel width, strip steel thickness, strip steel length and so on.

[0019] When determining the width of the strip, determine the parameters of the strip, specifically: determine whether the strip is trimmed; if the strip is trimmed, use the strip width after trimming as the strip wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com