Sampling circuit of automotive fuel gauge and fault diagnosis method thereof

A sampling circuit and fault diagnosis technology, which is applied to liquid level indicators, measuring devices, and instruments for physical variable measurement, can solve problems such as inaccurate reflection of remaining oil volume, increased component failure rate, and inaccurate values, and achieve Improve troubleshooting efficiency, reduce maintenance costs, and quickly troubleshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

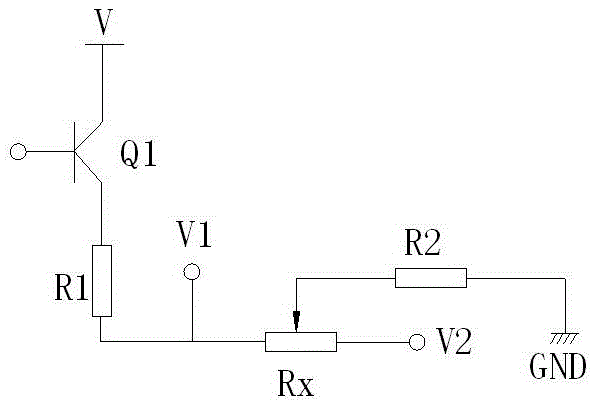

[0019] Such as figure 1 As shown, the sampling circuit of the vehicle fuel gauge of this embodiment includes a power supply V, an NPN transistor Q1, a voltage dividing resistor R1, a variable resistor Rx, a balancing resistor R2, and an AD conversion unit, a storage unit, and a display unit. The controller, the power supply V is connected to the first end of the balance resistor R2 through the NPN transistor Q1 and the voltage dividing resistor R1, the first end of the balance resistor R2 is used as the first sampling point, and the first end of the balance resistor R2 The two ends are suspended and used as the second sampling point; the slider end of the balance resistor R2 is connected to the reference ground terminal GND of the power supply V through the balance resistor R2; the collector of the NPN transistor Q1 is connected to the power supply V, and the base is used as a sampling control The terminal is connected to the controller, and the emitter is connected to the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com