Tedder with improved terrain following

A lawn mower and ground technology, applied in 1] the field of the present invention, to achieve the effect of improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

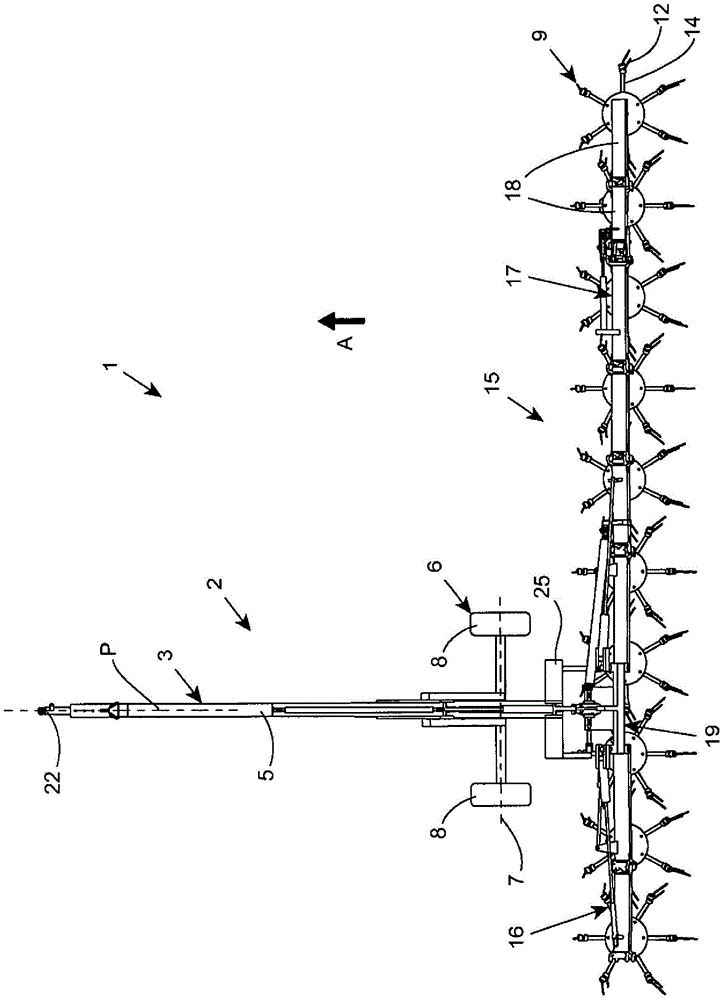

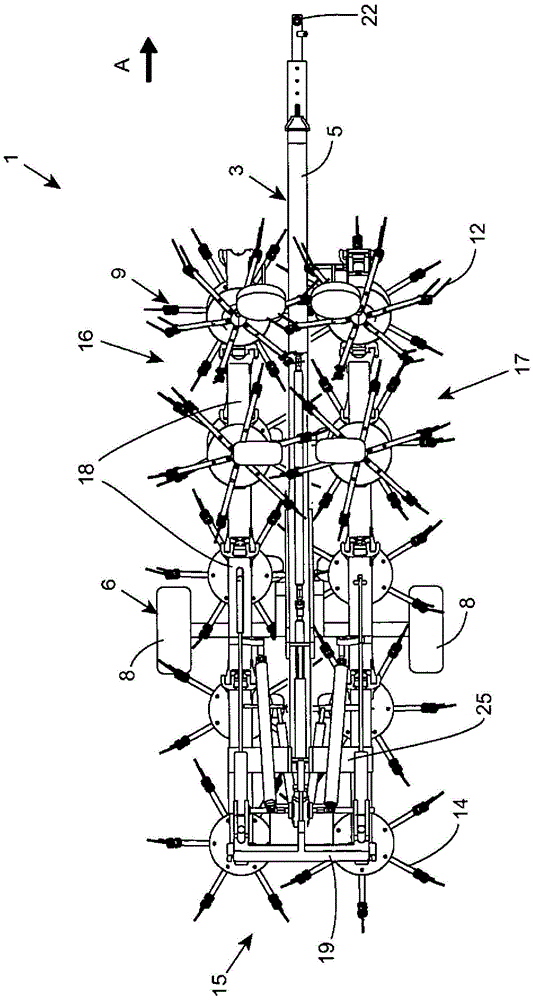

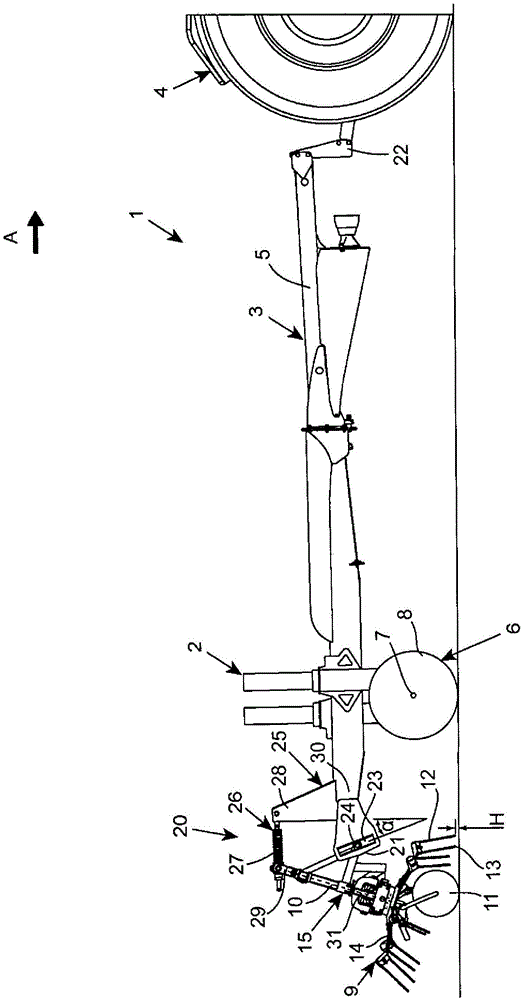

[0012] Such as figure 1 , 2 and 3, the machine (1) according to the invention is a lawnmower of the tumbling type. The machine (1) comprises a frame (2). The frame (2) comprises a front part (3). The front part is intended to be hitched to a tractor (4) that can move the machine (1) in the forward direction A. In the following description, the concepts "front", "rear", "left", and "right" are all defined relative to the forward direction (A), while the concepts "up" and "down" are defined relative to the ground. The front part (3) in particular comprises a tiller (5) whose length is substantially parallel to the direction of advance (A). The front part (3) is also provided with a ground support member (6) that can rotate relative to the front part (3) around a transverse axis (7). According to the embodiment in the figures, the ground support member (6) comprises at least one wheel (8) rotatable around said transverse axis (7). For example, the ground support member (6) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com