Cleaning device and heat recovery system thereof

A technology of cleaning device and heat recovery device, which is applied in the direction of household cleaning device, cleaning equipment, tableware washing machine/rinsing machine, etc., and can solve the problems of limited overall cost, operating time/efficiency and performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

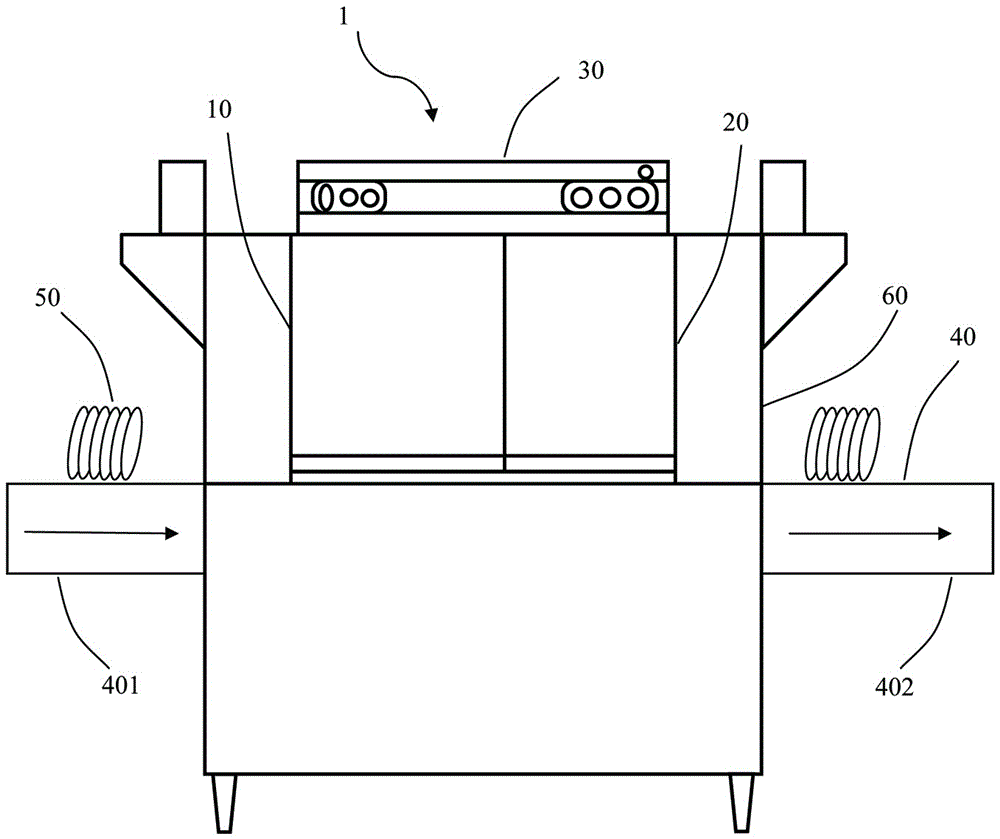

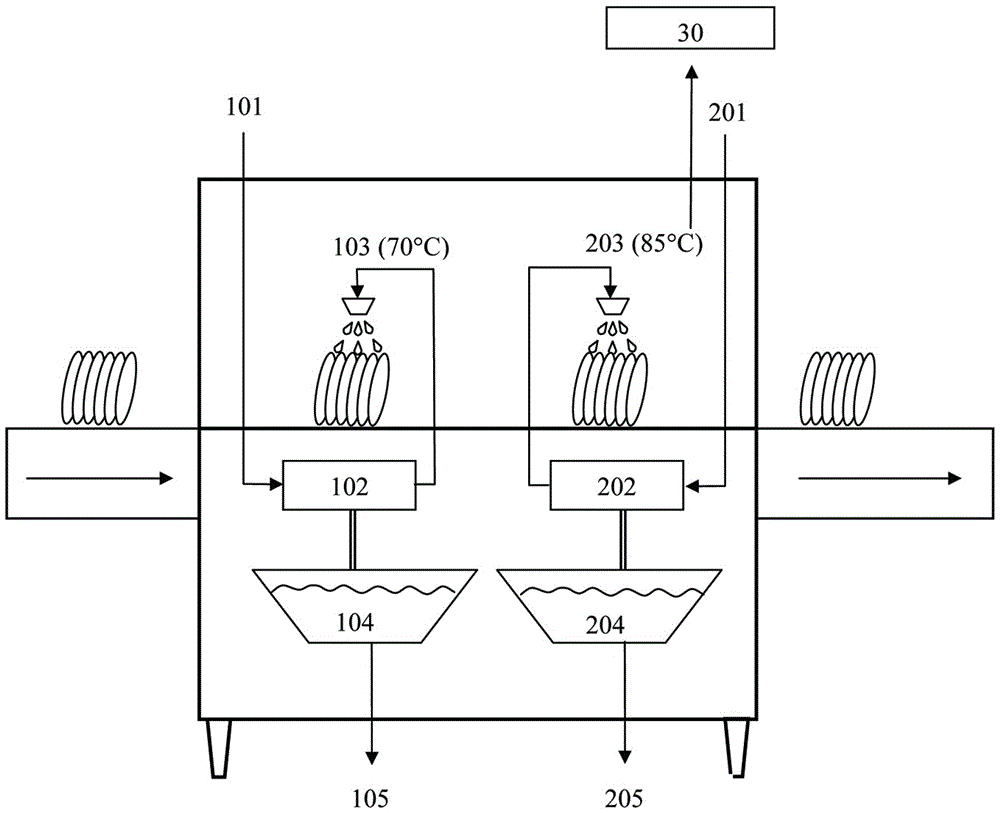

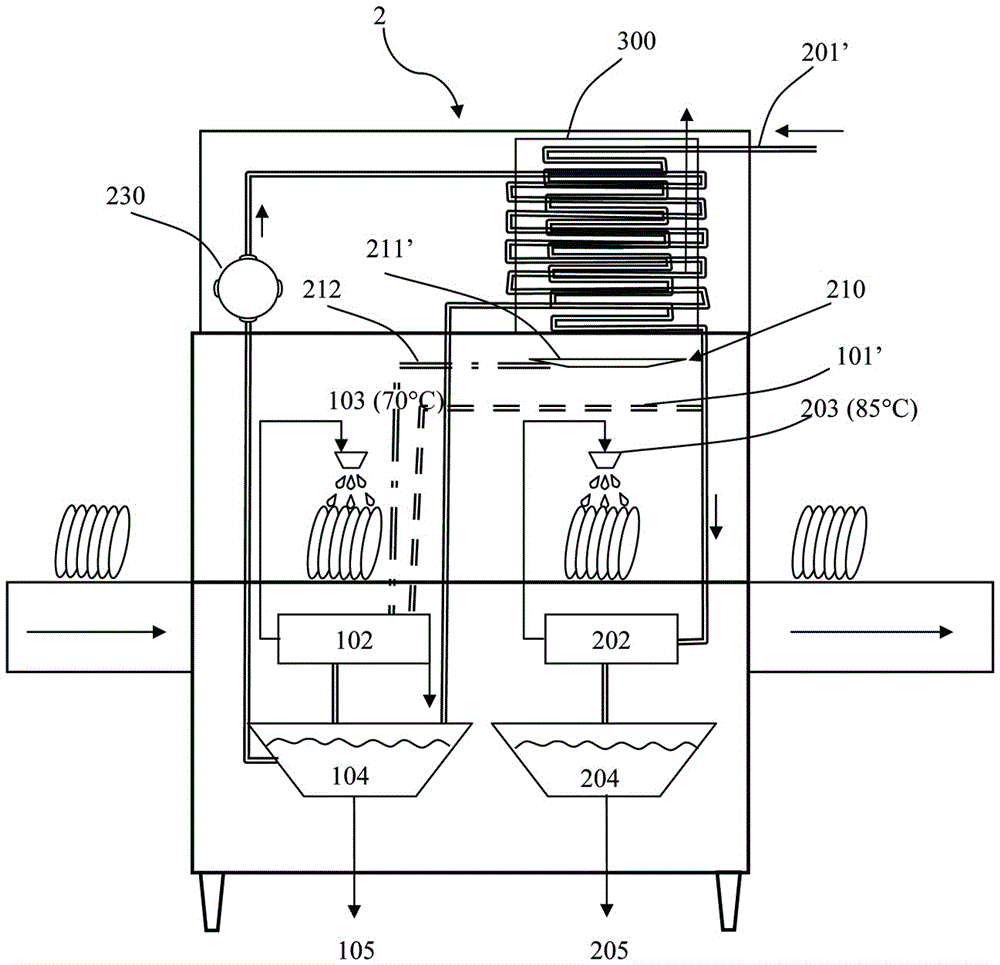

[0026] refer to image 3 , is a schematic perspective view of a cleaning device 2 with a heat recovery device according to an exemplary embodiment of the present invention. The structure and configuration of the cleaning equipment 2 are substantially the same as those of the above-mentioned prior art cleaning equipment 1, which includes two-stage cleaning devices 10, 20 arranged in series or in cascade, but further includes a heat recovery device 300 and correspondingly adapted water input units 101 ′, 201 ′ and / or other units / components etc. in order to fully recover the heat generated by the cleaning device 2 for reuse.

[0027] The heat recovery device 300 can be a thermal block, fin stack and / or heat exchange device made of heat storage material, which has good thermal conductivity and optional shape to store and transfer thermal energy efficiently. As shown, heat recovery unit 300 is optionally provided as part of steam processing unit 30 . Preferably, it can be arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com