Gas pipeline encounters high temperature automatic closing device

A technology of automatic closing device and gas pipeline, applied in fire rescue and other directions, can solve the problem of inability to quickly interrupt gas transmission, and achieve the effect of stable fire prevention effect, wide application and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

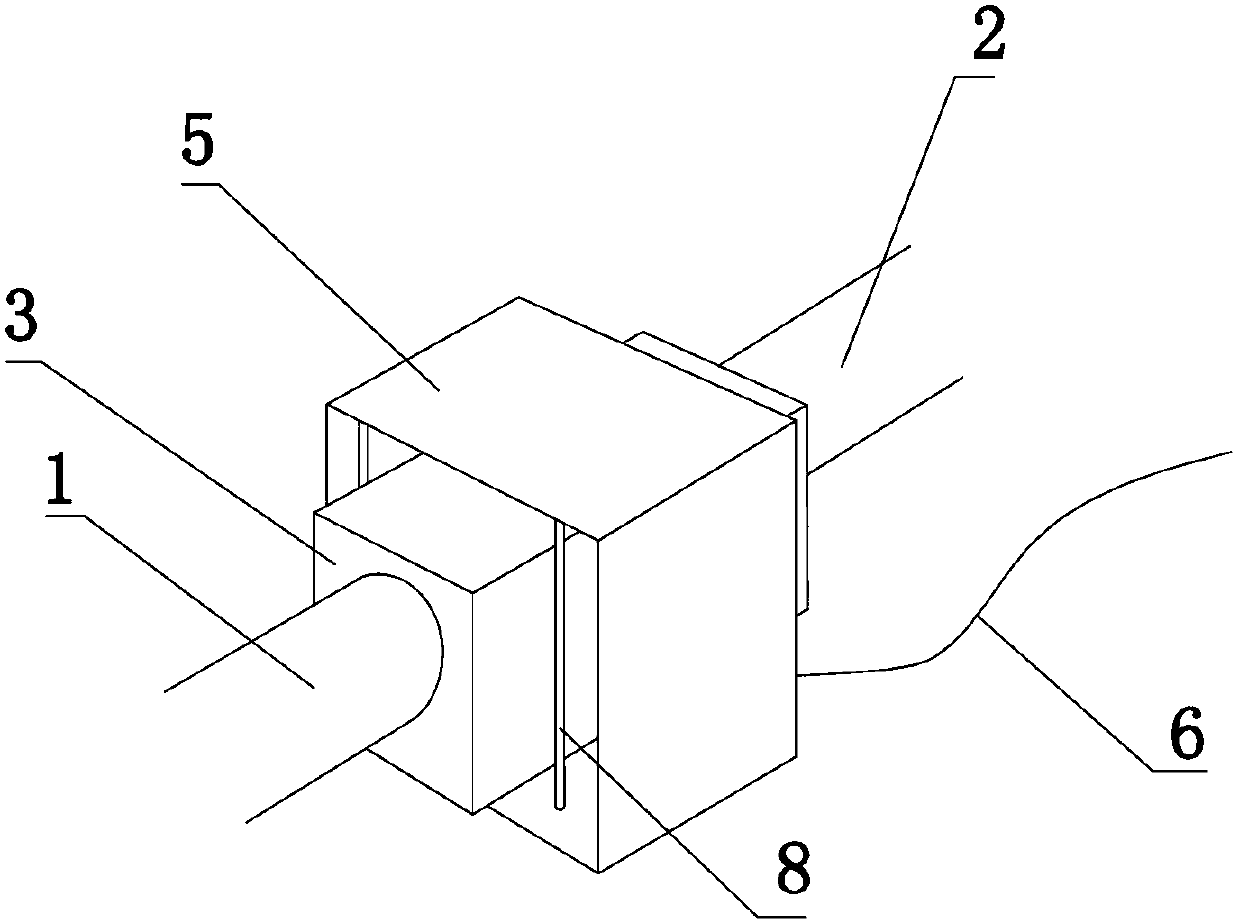

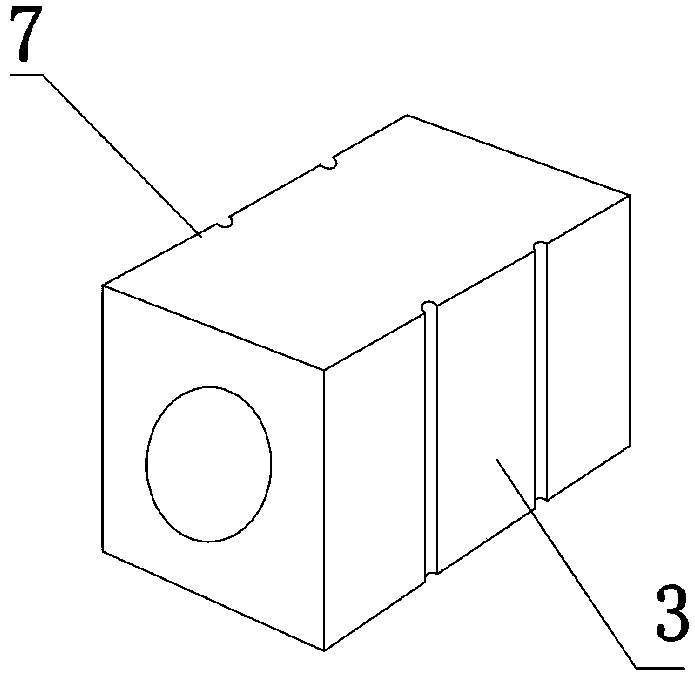

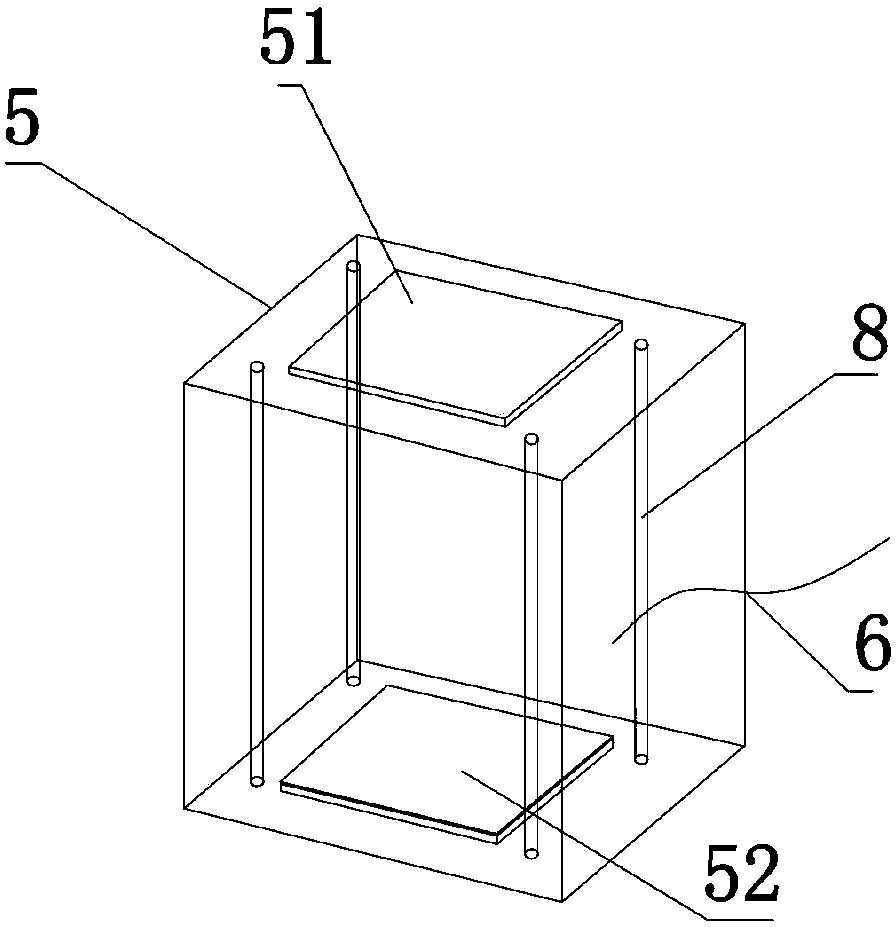

[0021] Such as figure 1 As shown, the device for automatically closing the gas pipeline in case of high temperature includes a first gas pipeline 1 and a second gas pipeline 2. A section of casing 3 is sealed between the first gas pipeline and the second gas pipeline. A baffle plate 4 is hinged below the pipe opening of a gas pipeline, and the baffle plate is soft iron; a metal frame 5 is arranged around the casing; A second magnet 52 is provided, and the second magnet is nickel-iron alloy; the baffle plate, the first magnet, and the second magnet are on the same vertical line. The size standard of the metal frame in the present invention is: when the metal frame is in the middle position, there should be a sufficient distance between the metal frame and the casing, and this distance will prevent the baffle plate from being affected by the first magnet or the second magnet .

[0022] Such as Figure 4 As shown, the automatic closing device of the gas pipeline in case of hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com