Automatic Spot Welding Diaphragm Machine

An automatic spot welding and diaphragm technology, applied in welding equipment, resistance welding equipment, welding/welding/cutting items, etc., can solve the problems of poor consistency, affecting product performance, and the product qualification rate cannot reach 100%, Achieve the effect of ensuring consistent quality and performance, maintaining consistency and reliability, and reducing the risk of customer complaints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

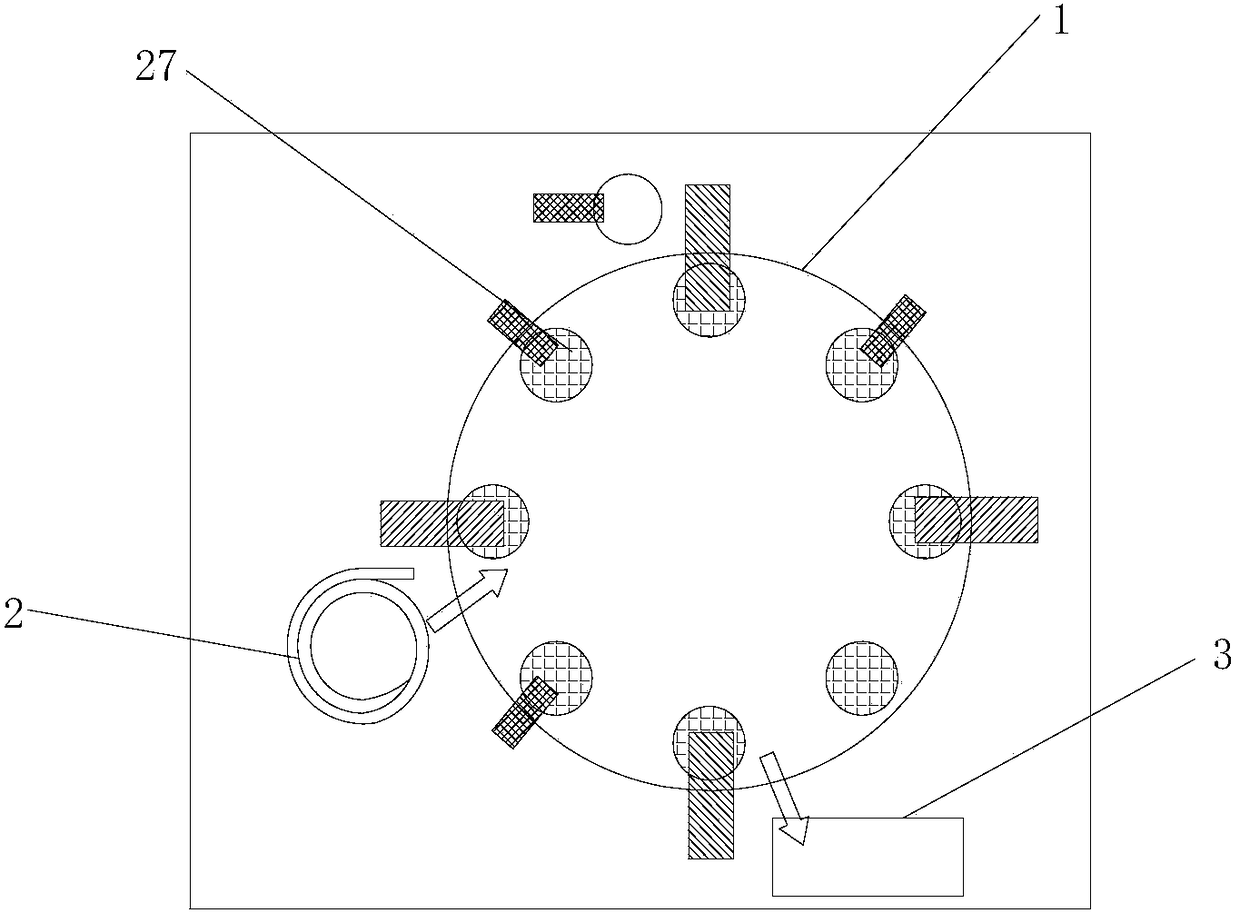

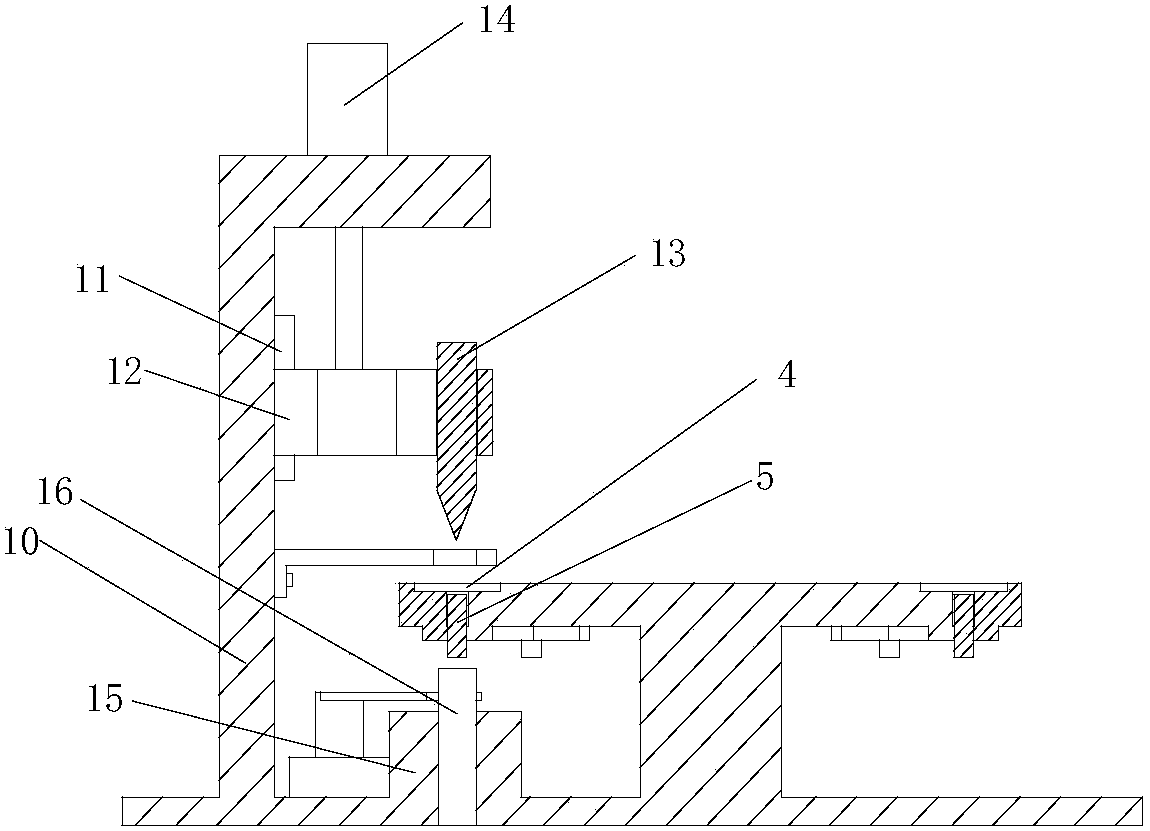

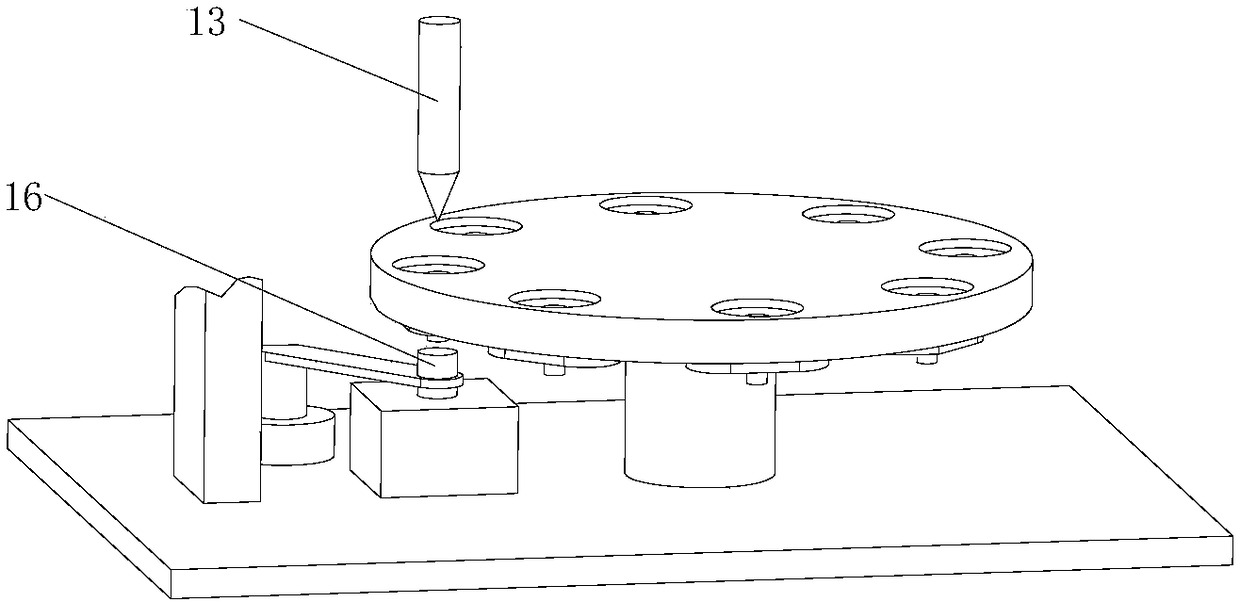

[0021] see figure 1 As shown, the automatic spot welding diaphragm machine is characterized in that it includes a rotating disk 1 arranged on the workbench and a first feeding device, a second feeding device, a spot welding device and a rotating disk clockwise arranged on the working table. Unloading device; at least one circulation tool is evenly distributed on the outer peripheral surface of the turntable; the first feeding device includes a shaker tray 2, a push-out cylinder and a first manipulator; the second feeding device includes a diaphragm placement device and the second manipulator used in conjunction with the film placement device; the unloading device includes a receiving box 3 and a third manipulator; the flow transfer tool includes a placement groove 4 arranged on the turntable, and the placement groove is provided with copper core 5;

[0022] The diaphragm placement device includes a base 7 with a jack, in which a "T" shaped diaphragm tooling 8 is arranged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com