Mechanism capable of implementing six-degree-of-freedom adjustment of large workpieces

A technology with large workpieces and degrees of freedom, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of attitude adjustment interference of large rotary parts, and achieve the effect of no jamming, flexible adjustment process, and damage protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

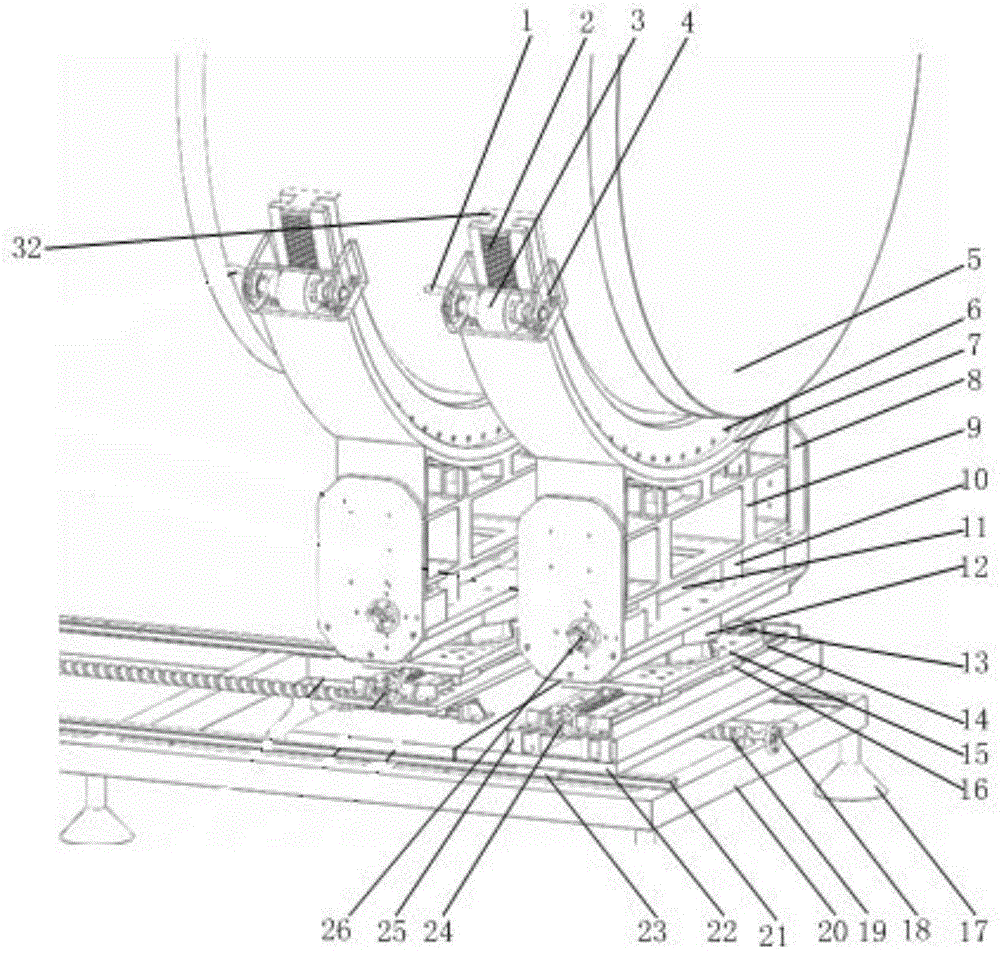

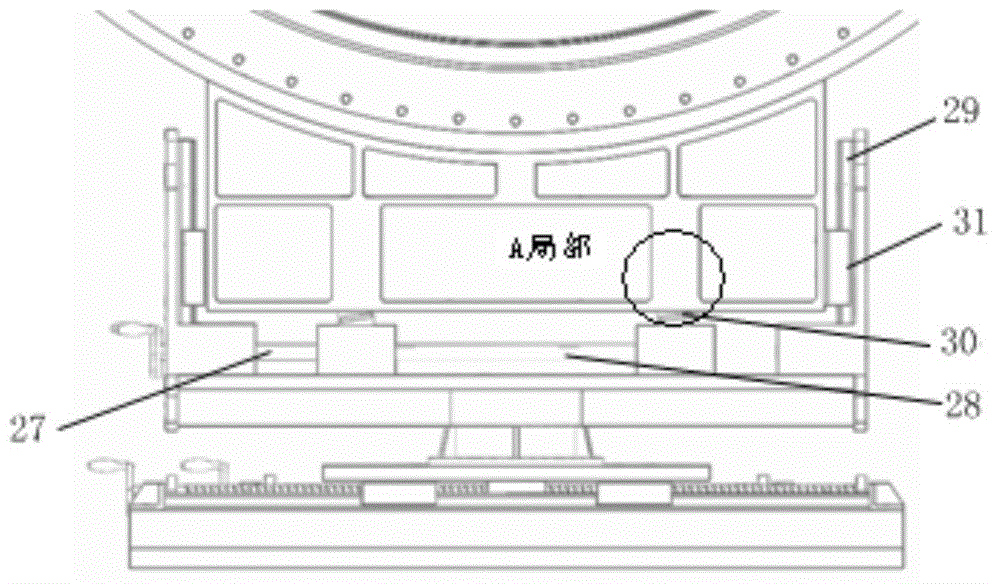

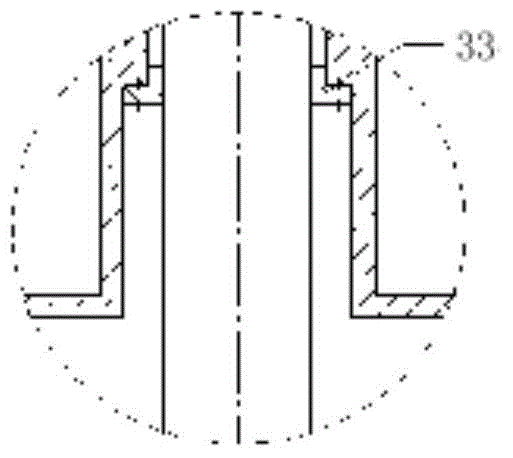

[0019] A mechanism that can realize six degrees of freedom adjustment of large workpieces according to the present invention will be introduced below in conjunction with the accompanying drawings and embodiments:

[0020] like figure 1 As shown, a mechanism that can realize the six-degree-of-freedom adjustment of a large workpiece includes two single-bracket assemblies, and the two single-bracket assemblies are installed side by side, and the adjusted part 5 is installed on the upper part of the two single-bracket assemblies. The rear single bracket assembly is an active bracket, and the front single bracket assembly is a follower bracket. The two single-bracket components are 5-DOF brackets, and the 5 DOFs include three translation degrees of freedom, one rotation degree of freedom and one follow-up rotation degree of freedom.

[0021] In this embodiment, the 5-DOF single bracket assembly includes an X-direction rail assembly, a Y-direction rail assembly, a Z-direction rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com