Surface polishing and grinding machine

A polishing machine and polishing head technology, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of inconvenient polishing, complex polishing equipment, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below according to the drawings and embodiments.

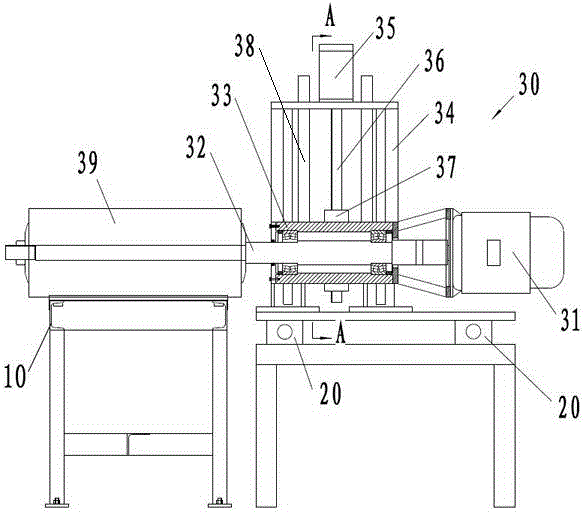

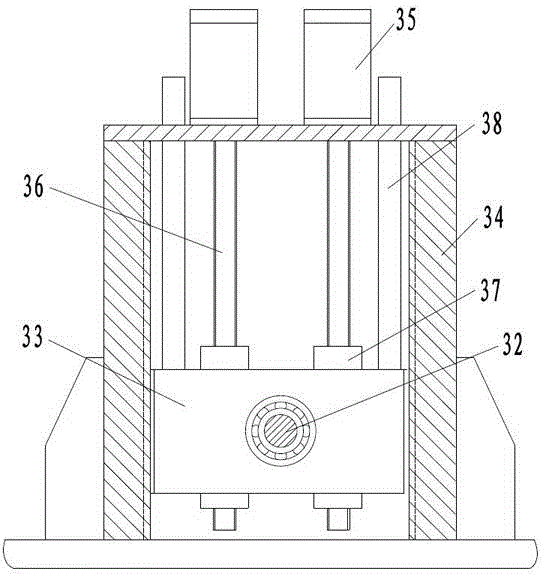

[0015] Such as figure 1 and figure 2 As shown, a surface polishing machine described in an embodiment of the present invention is applied in a surface polishing device. The surface polishing device includes a workbench 10 and a surface polishing machine arranged on the side of the workbench 10. The surface polishing machine includes two parallel linear guide rail modules 20 and a movable top of the linear guide rail module 20. Polishing device 30, polishing device 30 comprises motor 31, and motor 31 is connected with horizontal rotating shaft 32 by shaft coupling, and rotating shaft 32 passes through and extends floating bearing mounting seat 33, and the both sides of floating bearing mounting seat 33 pass guide rail and Guide groove is installed on the adjusting frame 34, and the top of adjusting frame 34 is equipped with stepping motor 35, and stepping motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com