Natural centering hoisting method of block pattern masonry wall

A technology for masonry and wall pieces, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of difficulty in realizing hoisting points of various shapes of wall pieces, various shapes of wall pieces, and poor stability of wall pieces. To achieve the effect of easy assembly operation, strong versatility, and reduce the difficulty of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

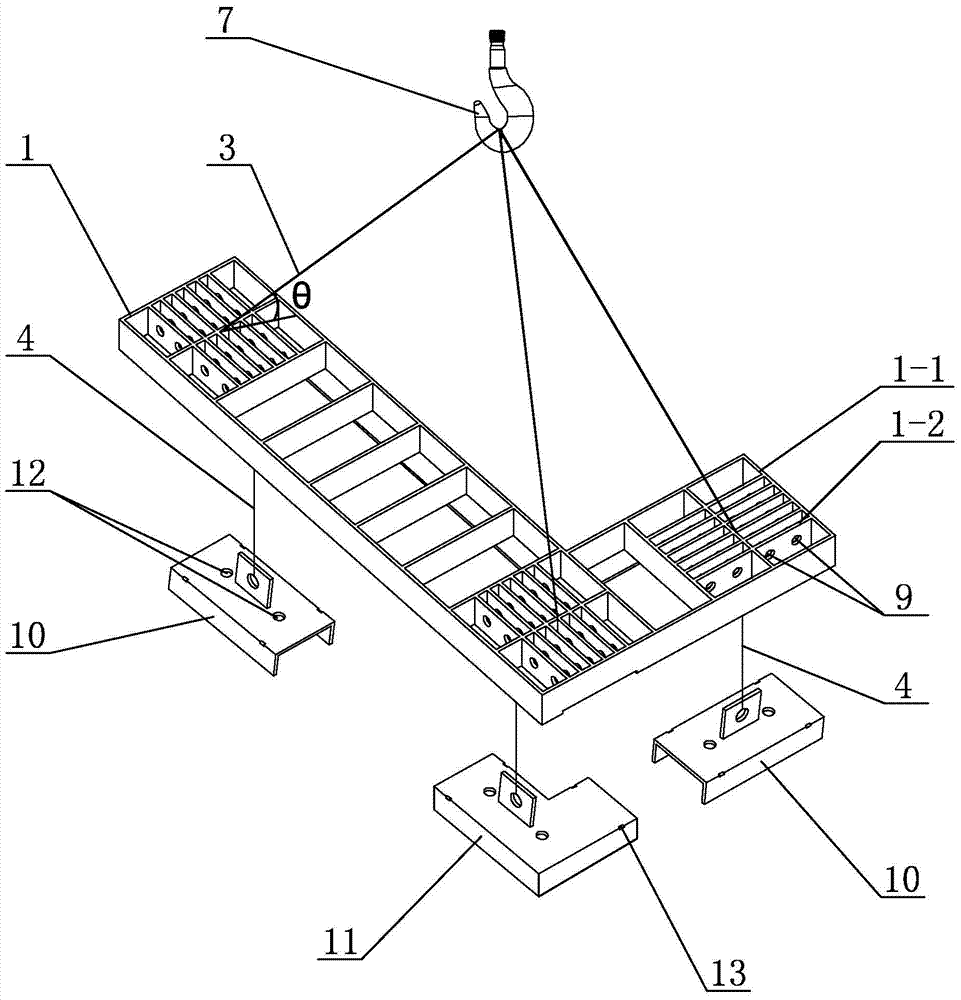

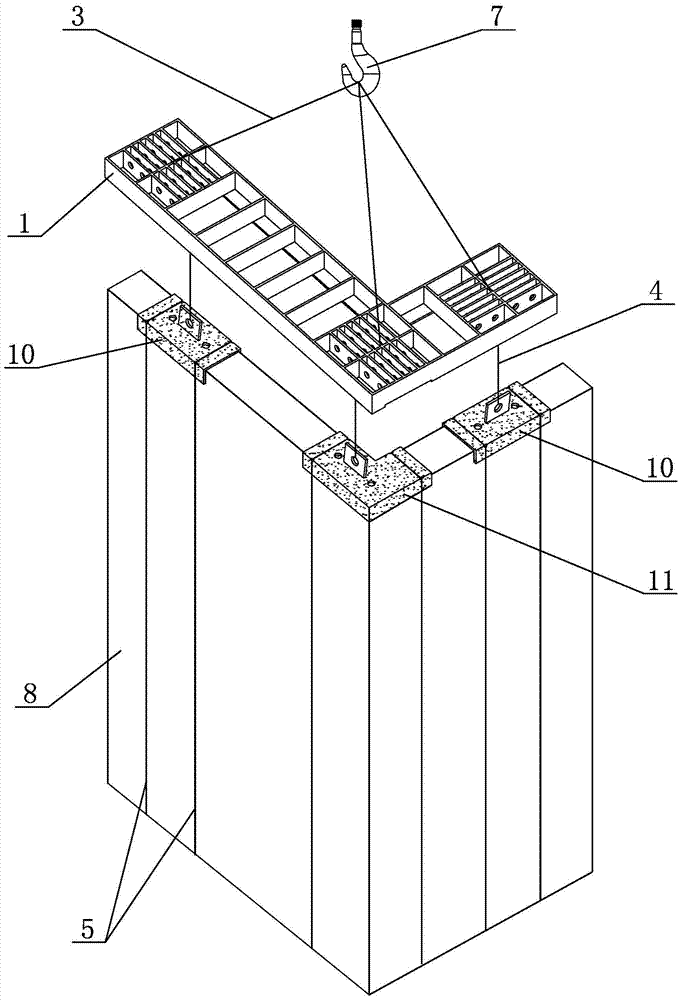

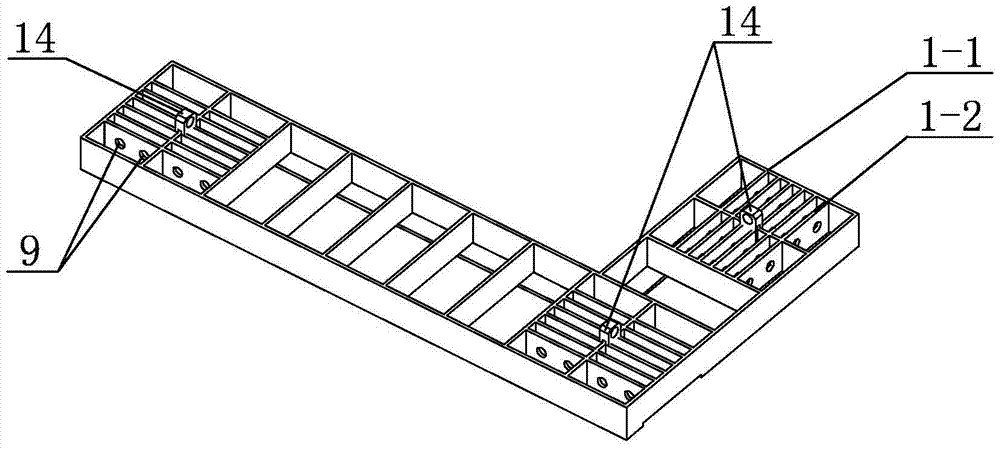

[0029] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Describe this embodiment, in this embodiment, the ABM natural centering method comprises the following steps:

[0030] Step 1: Select the balance beam 1: select the balance beam 1 corresponding to the shape of the hollow block masonry wall piece 8 according to the shape of the hollow block masonry wall piece 8 to be hoisted;

[0031] Step 2: Calculate the center of gravity of the hollow block masonry wall piece 8: calculate the position of the center of gravity of the hollow block masonry wall piece 8, set the hollow block masonry wall piece 8 vertically, and select a hollow block masonry wall piece 8 The vertical horizontal plane of the wall sheet 8 is the reference horizontal plane, and the center of gravity of the hollow block masonry wall sheet 8 on the reference horizontal plane is the centroid C(x...

specific Embodiment approach 2

[0056] Specific embodiment 2: This embodiment is a further limitation of specific embodiment 1. In this embodiment, the natural centering hoisting method of block pattern masonry wall pieces also includes the step of inspecting the ropes, which is located between step 5 and step 6. After step 5 is completed, check the connection status and stability of multiple hoisting ropes 3, multiple connecting ropes 4 and multiple binding ropes 5. After the inspection, drive the hook 7 to hoist the hollow block masonry wall piece 8 . The operation steps of checking the ropes in this embodiment can improve the positioning accuracy of the hollow block masonry wall piece 8 and the stability during the hoisting process of the present invention.

specific Embodiment approach 3

[0057] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. In Step 4 of this embodiment, the line where the axis of the balance beam 1 in the longitudinal direction coincides with the area M is the line J. According to the sample test, the position of the line J is the best hoisting position. The optimal lifting point N is located on the line J. Because the area M has different numbers of small areas according to the shape of the balance beam 1, that is, there are multiple lines J and multiple optimal hoisting points N, and each small area has a line J and an optimal hoisting point N. Point N, the optimal lifting point N is located on the line J in the small area where it is located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com