Rotating mechanism with flexible shell

A technology of flexible casing and rotating mechanism, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of high price and large gaps, and achieve the effects of convenient operation, low material cost, and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

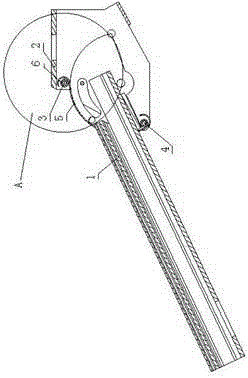

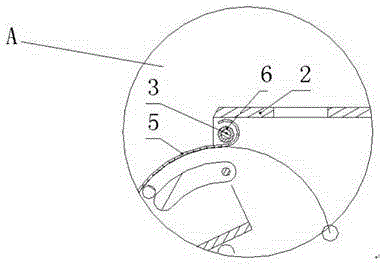

[0009] As shown in l and figure 2 The rotating mechanism of a kind of flexible casing shown, comprises electric arm 1, and electric arm 1 is connected with elbow fixed frame 2, and elbow fixed frame 2 is provided with upper rotating shaft 3 and lower rotating shaft 4, and electric arm 1 is provided with There is a flexible shell 5, one end of the flexible shell 1 is wound on the upper rotating shaft 3, the other end of the flexible shell 5 is wound on the lower rotating shaft 4, and springs 6 are arranged on the upper rotating shaft 3 and the lower rotating shaft 4;

[0010] When the electric arm rotates downwards, the upper part of the flexible housing is in a stretched state, which drives the flexible housing to move downward around the upper rotating shaft, and the lower part of the flexible housing is in a compressed state. Driven by the spring of the lower rotating shaft, the flexible housing turns into a downward rotation axis.

[0011] When the electric arm rotates upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com