Constant-temperature gas water heater and constant-temperature control method

A gas water heater, constant temperature control technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of low overall temperature of the pipeline, rising return water temperature, frequent start-up of preheating cycle devices, etc., and achieve economical and reasonable operation , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

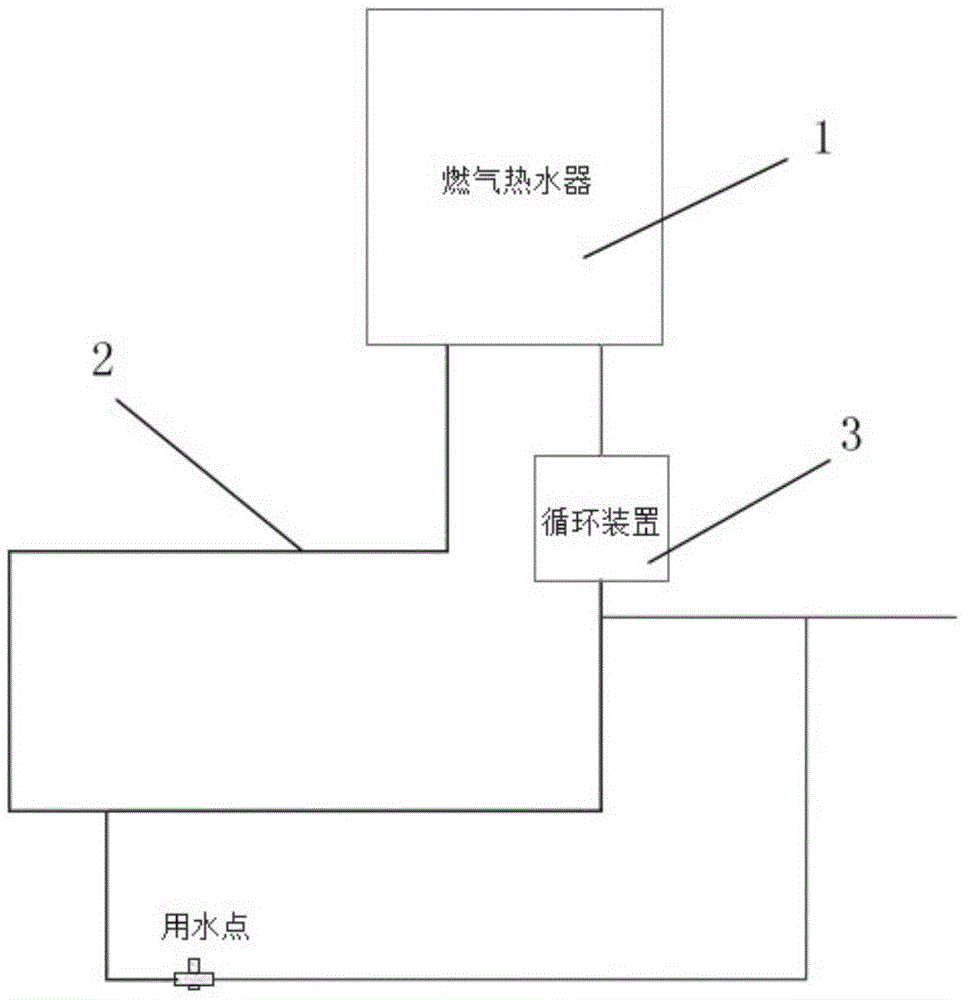

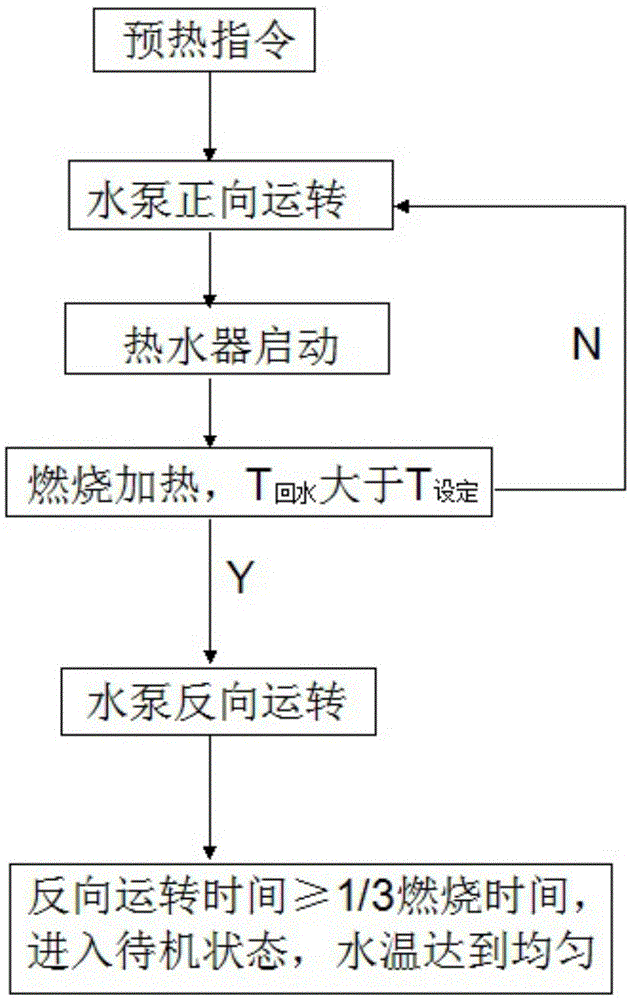

[0029] Such as figure 1 As shown, a constant temperature gas water heater includes: a gas water heater body 1, a circulation pipe 2 connected to the gas water heater body 1, and a circulation device 3 installed on the circulation pipe 2; it is characterized in that the circulation device 3 includes A forward circulation module and a reverse circulation module, the fluid in the circulation pipeline circulates forward under the action of the forward circulation module or reversely circulates under the action of the reverse circulation module.

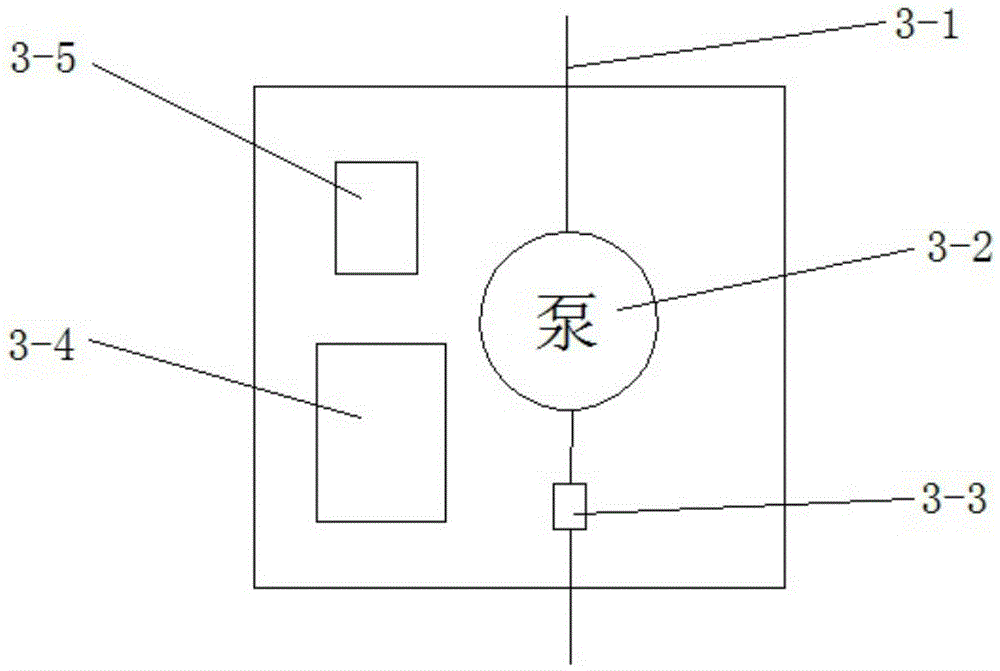

[0030] Such as figure 2 As shown, the circulation device 3 includes: a connecting pipeline 3-1, a circulation pump 3-2 that can be forward and reversed installed on the connecting pipeline 3-1, a temperature sensor 3-3, and the circulation pump 3-2, The controller 3-4 connected to the signal of the temperature sensor 3-3; the controller 3-4 controls the forward rotation or reverse rotation of the circulation pump 3-2 according to the si...

Embodiment 2

[0035] Such as Figure 4 As shown, the constant temperature gas water heater provided in this embodiment is basically the same in structure as that in Embodiment 1, the difference is that:

[0036] The circulation device 3 includes: a connecting pipeline 3-1, a circulation pump 3-2 installed on the connecting pipeline 3-1, a temperature sensor (not shown), a switchable steering first four-way valve 3-6 and an adjustable The second four-way valve 3-7 for switching steering, the first four-way valve 3-6 and the second four-way valve 3-7 are respectively connected to the two ends of the circulating pump 3-2, and a controller 3-4 is connected with the temperature The sensor, the first four-way valve 3-6, and the second four-way valve 3-7 are connected with signals; the controller 3-4 controls the first four-way valve 3-6 and the second four-way valve 3-6 according to the signal fed back by the temperature sensor 7 Switch the steering to realize the conversion of the circulation d...

Embodiment 3

[0039] Such as Figure 5 As shown, the constant temperature gas water heater provided in this embodiment is basically the same in structure as that in Embodiment 1, the difference is that:

[0040] The circulation device 3 comprises: a connecting pipeline 3-1, a temperature sensor (not shown) installed on the connecting pipeline 3-1, a first circulation pump 3-8 and a first shut-off valve 3-9, the first circulation pump 3-8 and the first shut-off valve 3-9 form a forward circulation module, and a second circulation pump 3-10 and a second shut-off valve 3-11 are connected in parallel at both ends of the forward circulation module, and the second circulation pump 3-10 The installation direction of the first circulation pump 3-8 is opposite to the installation direction, the second circulation pump 3-10 and the second shut-off valve 3-11 constitute a reverse circulation module, and a controller 3-4 communicates with the temperature sensor, forward Circulation module, reverse circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com