Flow calibration device for methane conveying pipeline

A technology for gas transmission pipeline and calibration device, which is applied in the energy field to achieve the effects of simple equipment, avoiding cumbersome procedures, and stable and reliable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

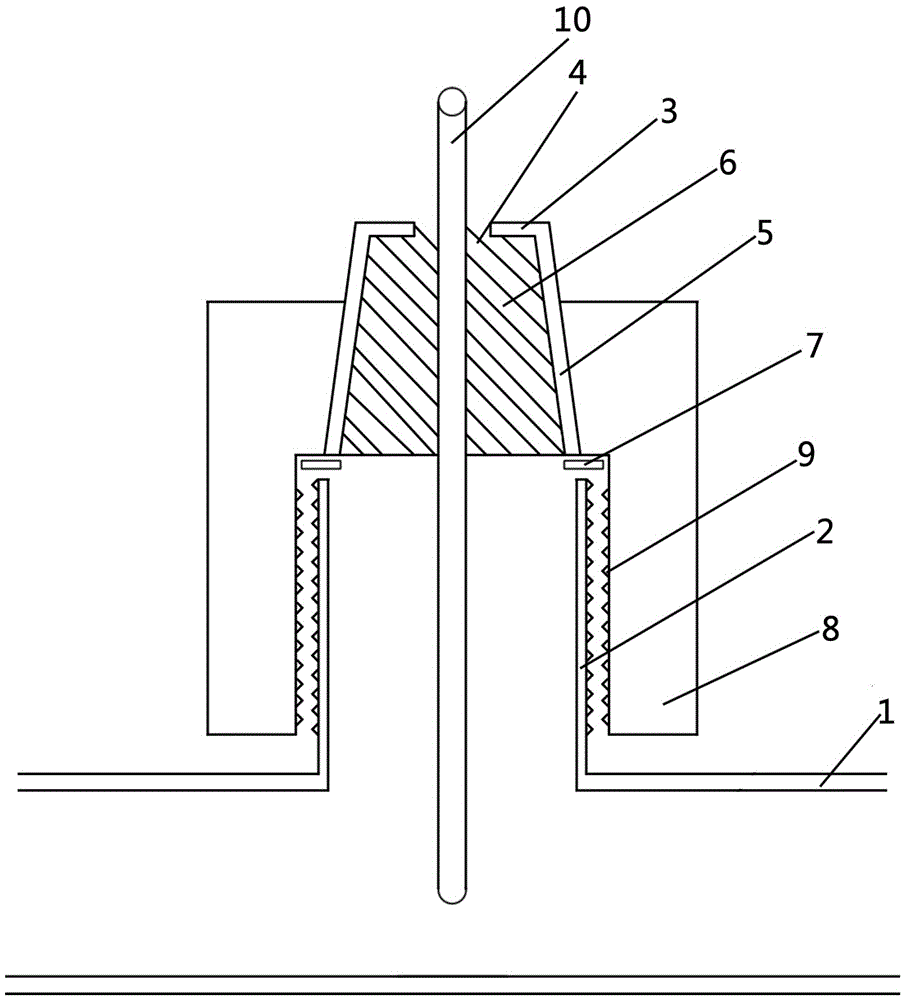

[0020] The biogas pipeline flow calibration device in this example is as follows: figure 1 As shown, it is mainly composed of a pipeline wind speed sensor 10, a rubber plug 6, a tapered sleeve 5 and a nut 8. It is characterized in that the pipeline wind speed sensor 10 is inserted into the rubber plug 6, and the rubber plug 6 is installed in the tapered sleeve 5. The tapered The sleeve 5 is fixed on the reserved orifice 2 of the biogas pipeline 1 through a nut 8 .

[0021] A limiting plate 3 is arranged on the conical sleeve 5 to limit the position of the rubber stopper 6 .

[0022] A sensor hole 4 is opened on the limiting plate 3 .

[0023] The nut 8 is connected to the reserved hole 2 through the thread 9, and a sealing gasket 7 is arranged at the joint between the nut 8 and the reserved hole 2.

[0024] The specific operation is as follows:

[0025] After punching a hole in the center of the rubber stopper 6, insert the tapered sleeve 5 from the lower end of the nut 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com