A performance testing device for flue gas pollution control equipment

A technology for pollution control and equipment performance, applied in measuring devices, sampling devices, analyzing gas mixtures, etc., to achieve the effects of convenient processing and installation, strong adaptability, and large coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043]Specific measurement example 1: evaluate the overall performance of pollutant treatment equipment.

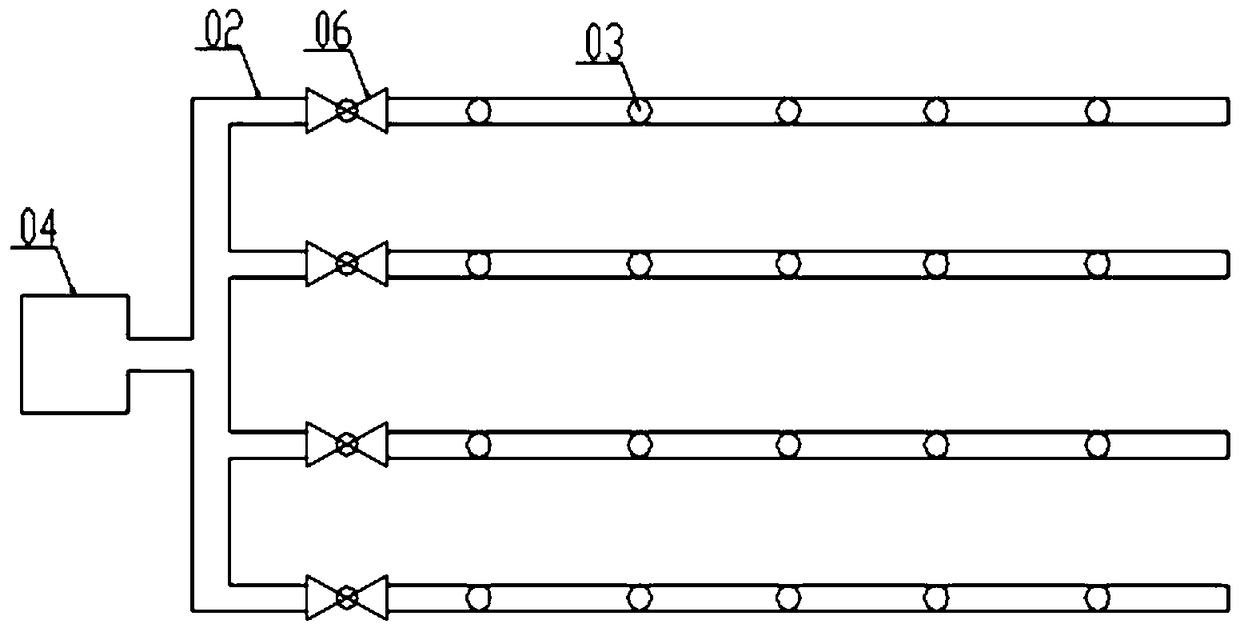

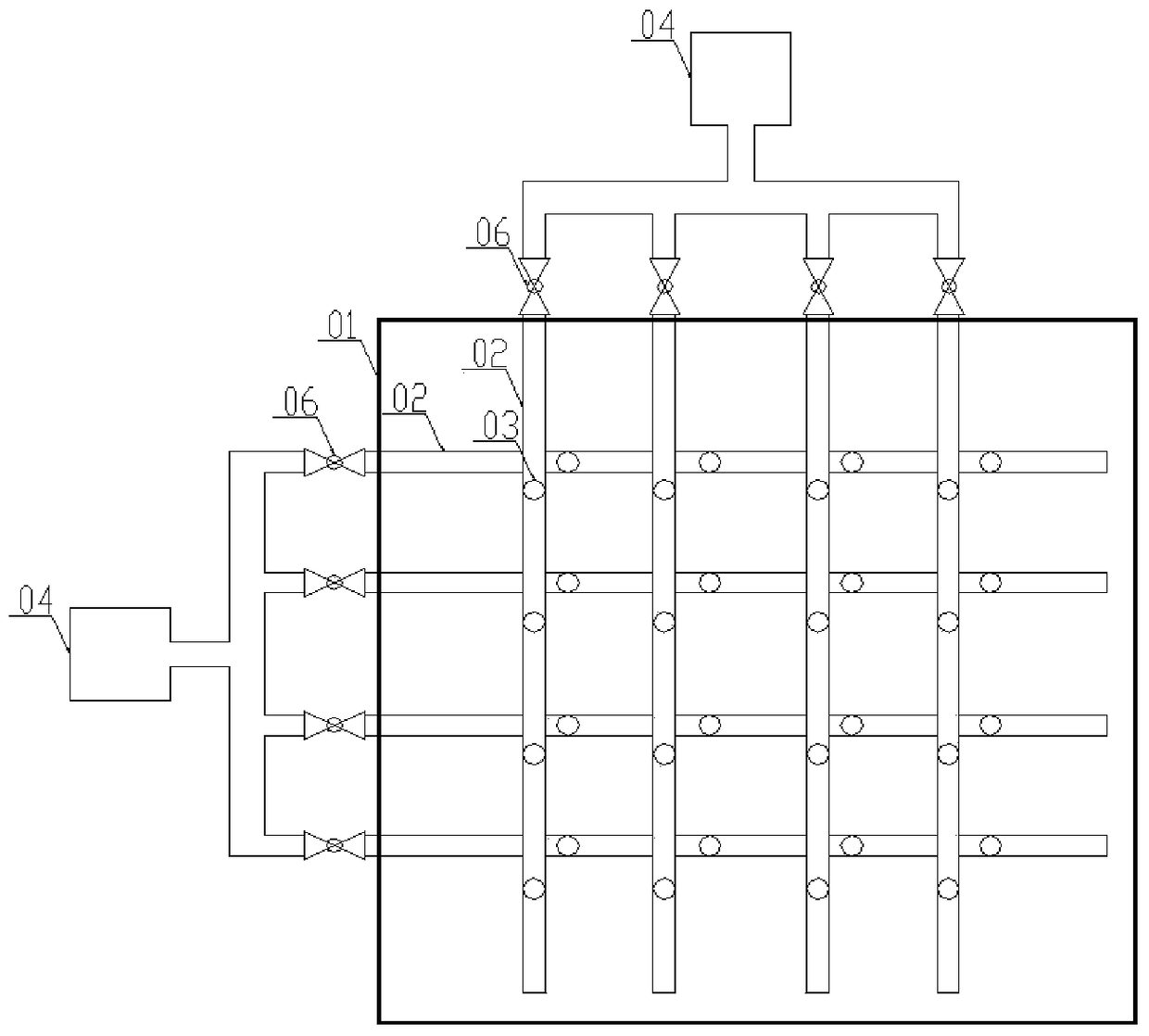

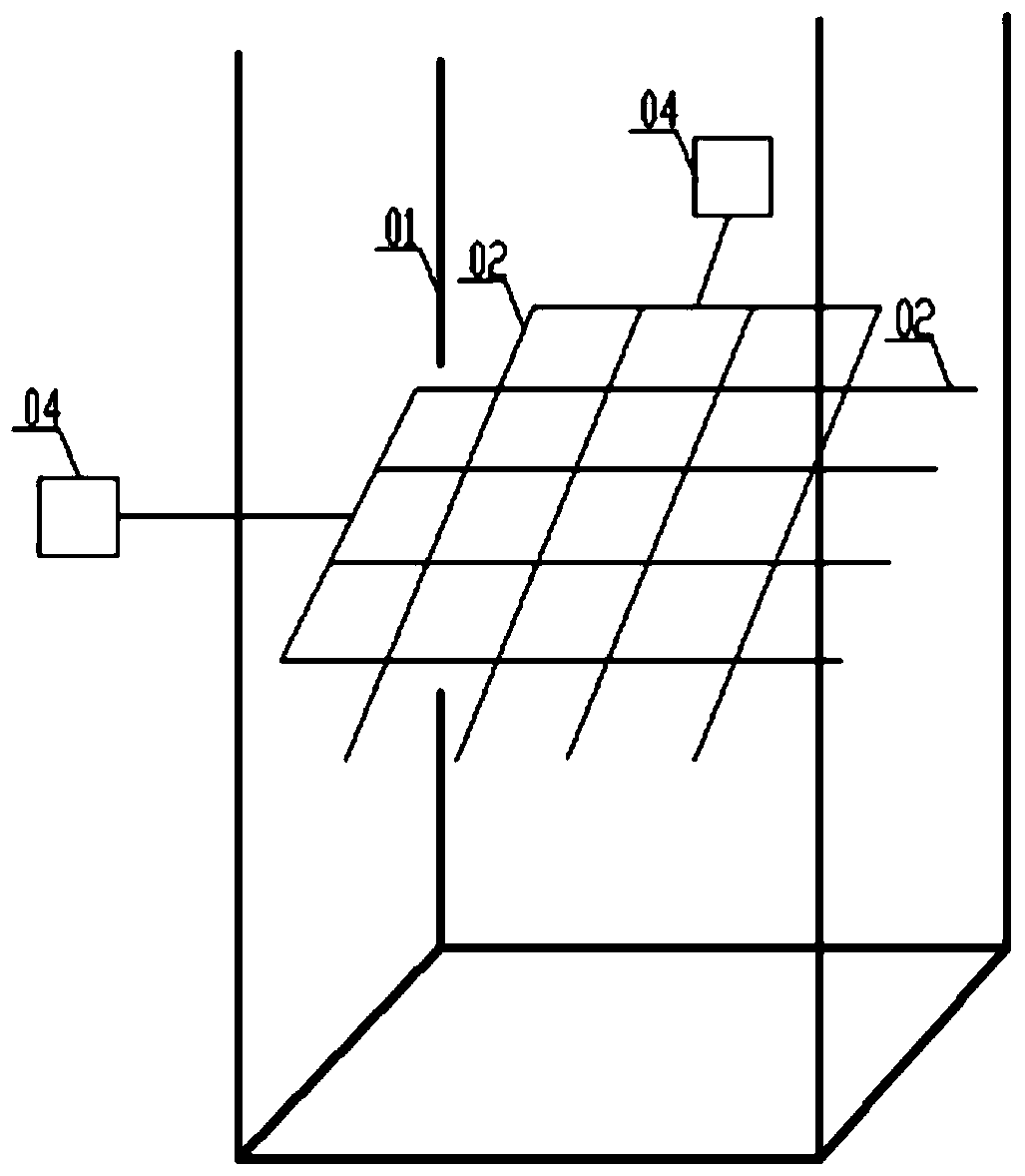

[0044] Taking the SCR denitrification reactor as an example, the sampling pipelines are arranged at the inlet and outlet of the SCR denitrification reactor respectively, and the arrangement is as follows: figure 2 , Figure 4 shown. Each group is provided with 4 sub-pipelines, and the numbers of the sub-pipelines crossed are A, B, C, D (the upper sampling line at the inlet and the upper sampling line at the outlet) and a, b, c, d (inlet The lower sampling line at the outlet and the lower sampling line at the outlet). When sampling and measuring, the flue gas composition at each sub-pipeline position is measured by opening and closing the control valve of the corresponding pipeline. Table 1 shows the measurement results of the inlet and outlet of the SCR denitration reactor:

[0045] Table 1 Overall performance evaluation of SCR denitration reactor measurement results...

specific Embodiment 2

[0049] Specific embodiment two: judging the fault area of the pollutant treatment equipment.

[0050] The catalyst in the middle area of a certain SCR denitrification reactor is partially deactivated, and its inlet and outlet are equipped with an ordinary flue gas composition measuring device. The measuring point is single and the length of entering the reactor is insufficient. The results are shown in Table 2:

[0051] Table 2 Measurement results of SCR denitrification reactor Common measuring device

[0052] NOx concentration

Ordinary measuring device mg / Nm 3

Entrance

332

Export

47

Denitrification efficiency

85.8%

[0053] It can be seen from the above table that although the catalyst in the middle area of the reactor is partially deactivated, this operation problem cannot be detected in time through the measurement results of the flue gas composition.

[0054] The reactor is equipped with the flue gas composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com