Fixture device for welding pipe structures

A fixture device and pipe fitting technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of fixed and inability to freely adjust the welding angle of pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

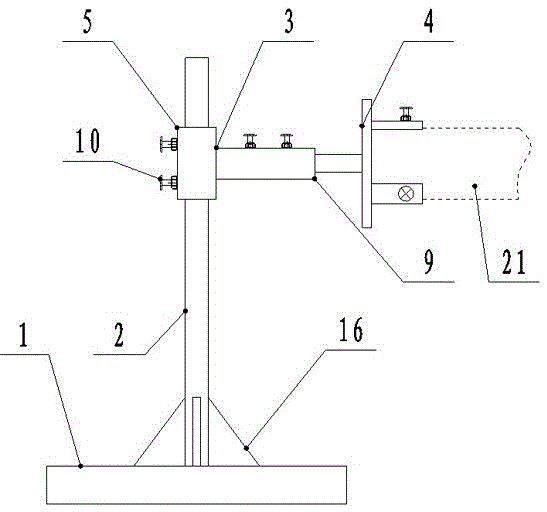

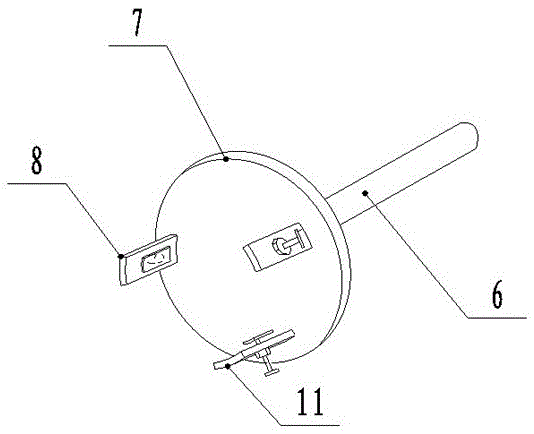

[0027] Such as Figure 1-2 As shown, a fixture device for pipe fitting structure welding according to the present invention includes a base 1, a column 2, a T-shaped joint 3 and a pipe chuck device 4, the column 2 is arranged on the base 1, and 5 sets of horizontal pipe joints of the T-shaped joint 3 It is arranged on the column 1; the connection between the column and the base 1 is provided with a reinforcing rib 16. The pipe chuck device 4 includes a shaft joint 6, a chuck 7 and jaws 8, the shaft joint 6 is arranged at the center of one disk surface of the chuck 7, and three pieces of jaws 8 are evenly distributed in a ring on the other disk surface of the chuck 7; The shaft connection 6 of the chuck device 4 is inserted into the longitudinal pipe connection 9 of the T-joint 3 .

[0028] Two sets of locking bolts 10 are arranged on the transverse pipe joint 5 of the T-shaped joint 3 . Two sets of locking bolts 10 are arranged on the longitudinal pipe joint 9 of the T-shape...

Embodiment 2

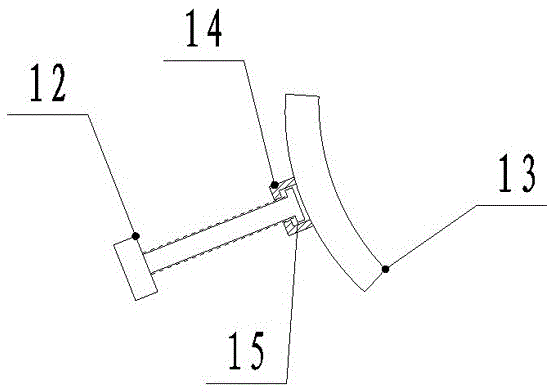

[0031] Such as image 3 As shown, the present invention is a fixture device for pipe fitting structure welding. On the basis of Embodiment 1, a buckle cap 14 is provided on the back of the clamping block 13, and a ring protrusion 15 is provided at the end of the fastening adjustment bolt 12. The fastening adjustment The end of the bolt 12 is set in the buckle cap 14 through the ring protrusion 15 , and the clamping block 13 is free to rotate around the end of the fastening adjusting bolt 12 . The clamping block 13 is arc-shaped.

Embodiment 3

[0033] Such as Figure 4 As shown, the present invention is a fixture device for pipe fitting structure welding. On the basis of Embodiment 1, the longitudinal pipe joint 9 of the T-shaped joint 3 is a bent structure. The longitudinal pipe joint 9 includes a fixed pipe joint 17 and a folded pipe joint 18, the fixed pipe joint 17 and the folded pipe joint 18 are connected by a groove interface and a raised joint, and the grooved joint and the raised joint Connected by a pin shaft 19, the groove interface and the protruding joint are positioned by a positioning bolt 20 to locate the folding angle, and the folding pipe joint 18 can be folded and rotated around the fixed pipe joint 17 through the pin shaft 19, and a positioning bolt 20 is provided on the groove interface Mounting holes are provided on the corresponding protruding joints with adjustment holes for the positioning of several positioning bolts 20. The positioning bolts 20 pass through the mounting holes and the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com