Batch-type amplitude-adjustable metal coiled material continuous chromatography color printing painting equipment

A technology for metal coils and coating equipment, applied in printing, printing presses, rotary printing machines, etc., can solve the unsolved problems of continuous color printing process on metal coils, and achieve the requirements of synchronous step-by-step positioning color printing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

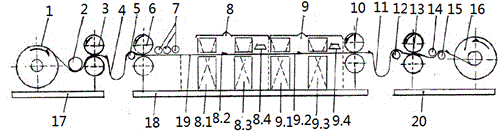

[0008] As shown in the figure, the intermittent type adjustable width metal coil continuous color printing and coating equipment of the present invention includes a printing device, an unwinding device and a winding device arranged at the left and right ends of the printing device.

[0009] The unwinding device includes an integral frame frame 17 . The unwinding equipment 1 with brake control, the unwinding passive roll 2 and the power unwinding pulling roll 3 are sequentially installed on the integral frame frame 17 of the unwinding device from left to right. The printing roll material is tightened by an oil pressure expansion device, driven by the control of the magnetic powder brake, and the power unwinding pulling roller 3 is pulled by the pinch roller, and the roll is unwound according to the set requirements. After unwinding, it enters the printing device. The metal coil forms an adjustable winding degree 4 between the unwinding device and the printing device.

[0010]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com