A vacuum antifreeze filling gun

A filling gun and vacuum technology, used in special distribution devices, packaging, distribution devices, etc., can solve the problems of insufficient pressure relief, water becoming, and loosening of tie rod nuts, so as to reduce the matching gap, ensure safe use, and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

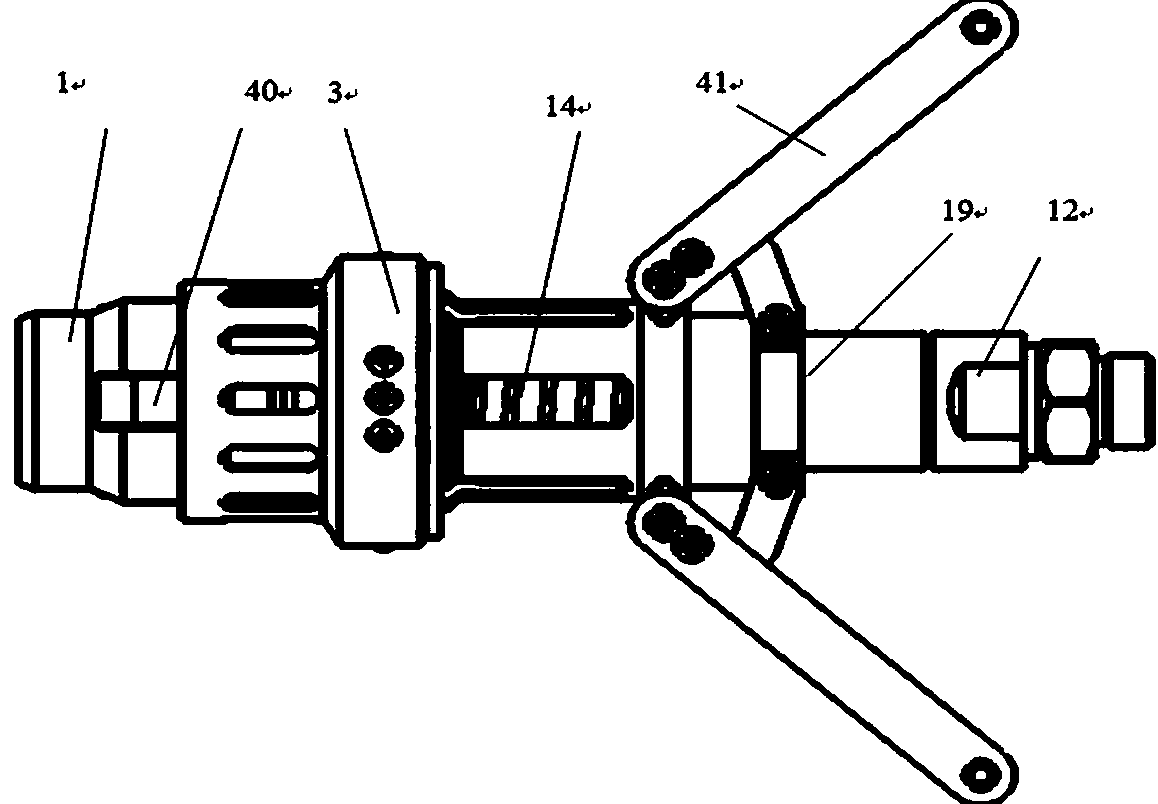

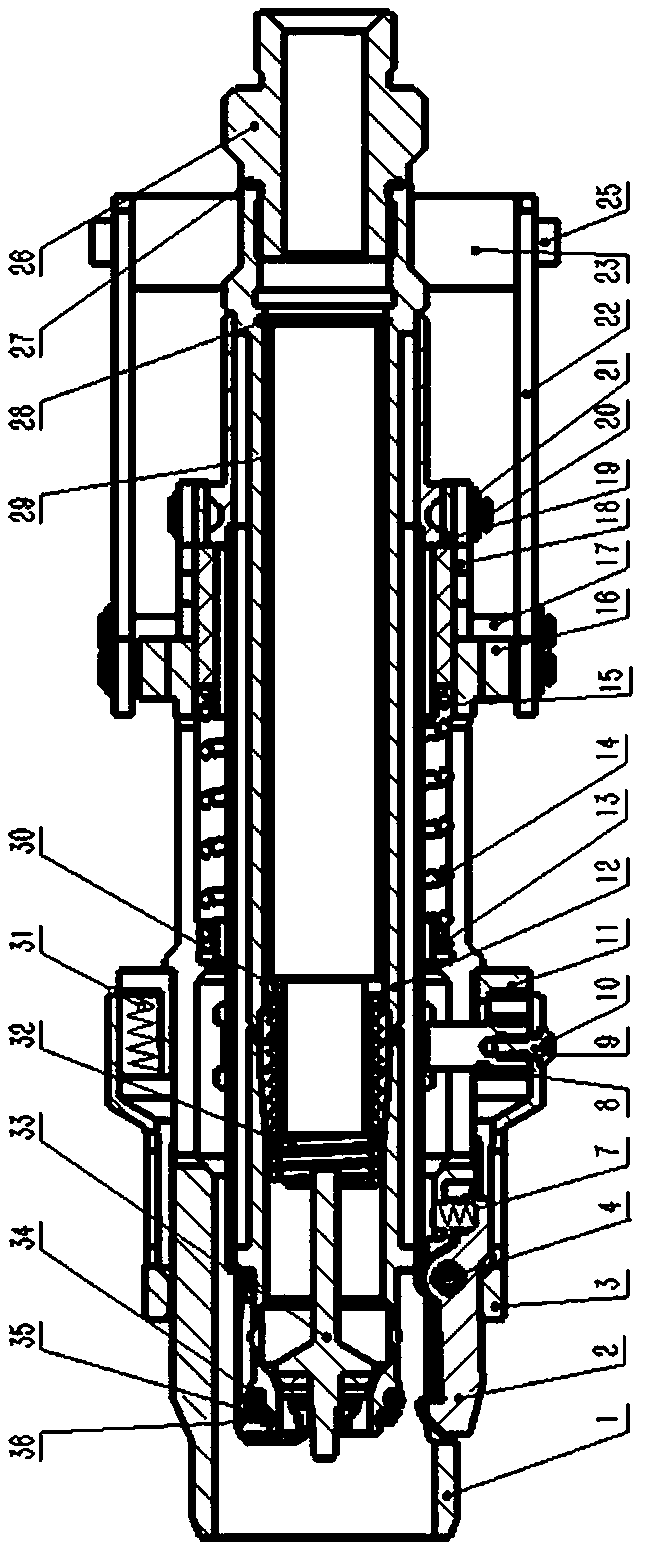

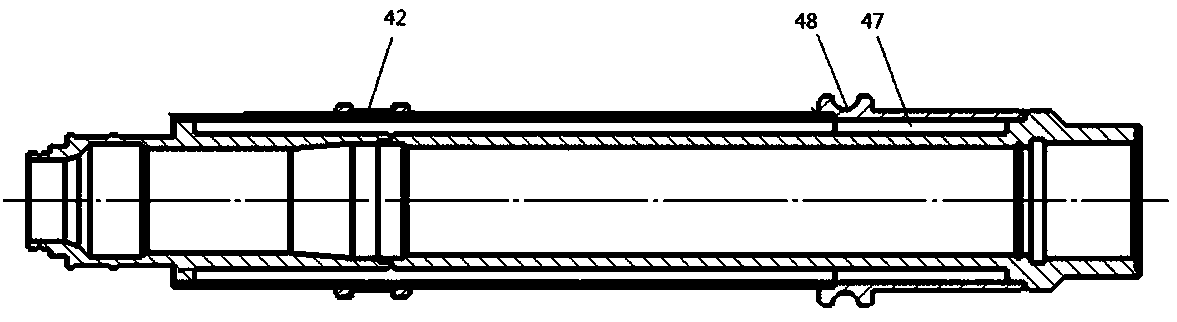

[0032] Such as Figure 1-7 As shown, a vacuum antifreeze filling gun of the present invention includes an outer casing 1, an inner casing 12, and a one-way valve core assembly; the outer casing 1 can be relatively slidably sleeved outside the inner casing 12, and the one-way valve The core assembly is hermetically installed at one end of the inner casing 12 ; a vacuum layer 47 is provided inside the wall of the inner casing 12 . The tube wall of the inner casing 12 includes a first tube wall and a second tube wall, the second tube wall is sleeved on the first tube wall, and the edge of the second tube wall sleeve is sealingly connected with the first tube wall, and is connected to the second tube wall. A vacuum layer 47 is formed between the wall and the first pipe wall, and the thickness of the vacuum layer 47 is 5-10 mm.

[0033]The rear end of the outer sleeve 1 is connected to the inner sleeve 12 through a handle mechanism 41, and a main spring 14 is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com