Aerator

An aeration and cylinder technology, applied in the field of aeration cylinders, can solve problems such as reducing power consumption, and achieve the effects of small pressure loss, improved dissolution efficiency, and convenient maintenance and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

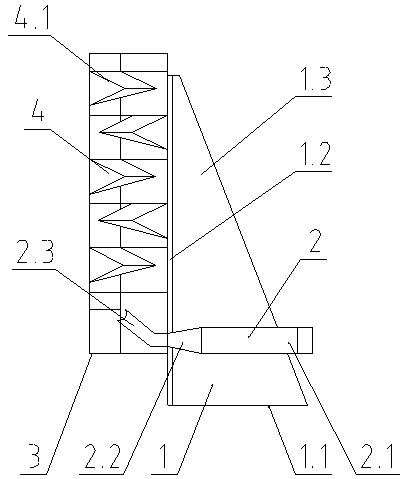

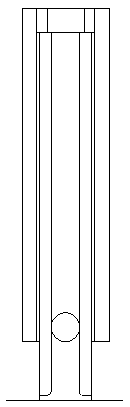

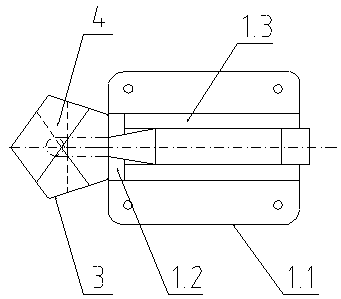

[0034] see Figure 1~Figure 3 , an aeration cylinder according to the present invention, which includes a mounting support 1, an aeration cylinder body 3 is arranged on one side of the installation support 1 along the vertical direction, the section of the aeration cylinder body 3 is polygonal, and the The polygonal aeration cylinder 3 is provided with a plurality of aeration blocks 4 from top to bottom, and the plurality of aeration blocks 4 are spirally arranged on the inner wall of the aeration cylinder 3 , and on the mounting support 1 An air supply pipe 2 is provided along the horizontal direction, the air supply pipe 2 is connected to the aeration cylinder body 3, and the air outlet of the air supply pipe 2 is located below a plurality of aeration blocks 4;

[0035] The mounting support 1 includes a base plate 1.1, a vertical support plate 1.2 is arranged on the base plate 1.1, two oblique support plates 1.3 are arranged between the vertical support plate 1.2 and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com