Elevator Mechanical Garage Lifting System

A technology of mechanical garage and lifting system, which is applied in the field of elevator-type mechanical garage lifting system, which can solve the problems of high space requirements on the top floor and obstacles to vehicle entry and exit, and achieve the effects of convenient vehicle entry and exit, reasonable structure, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

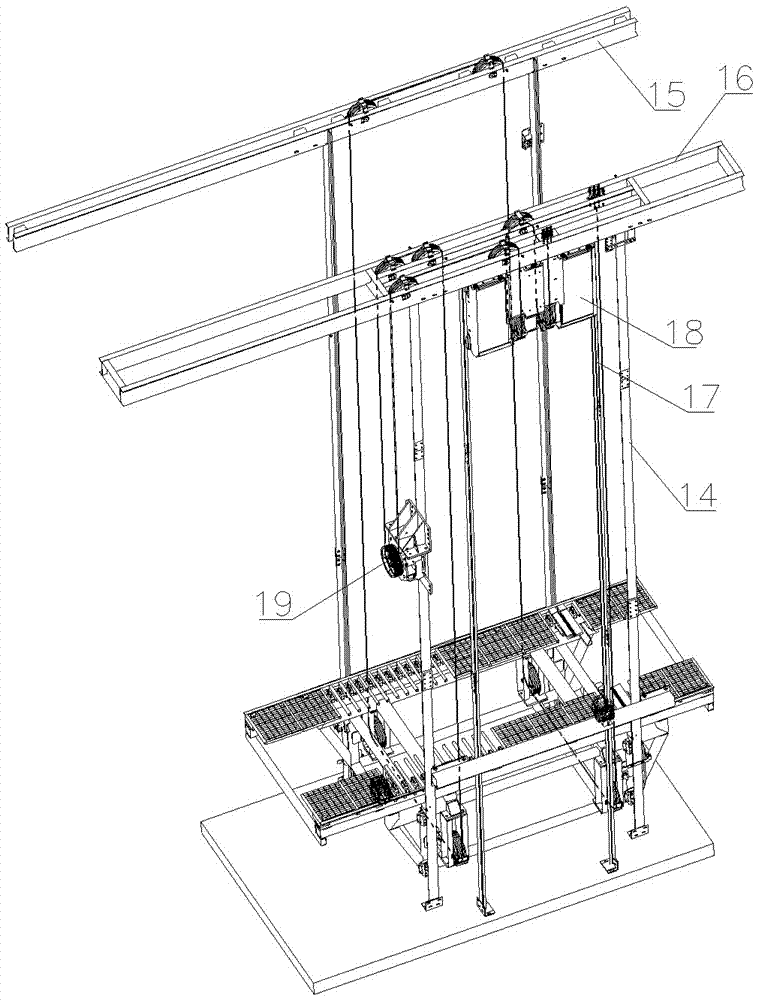

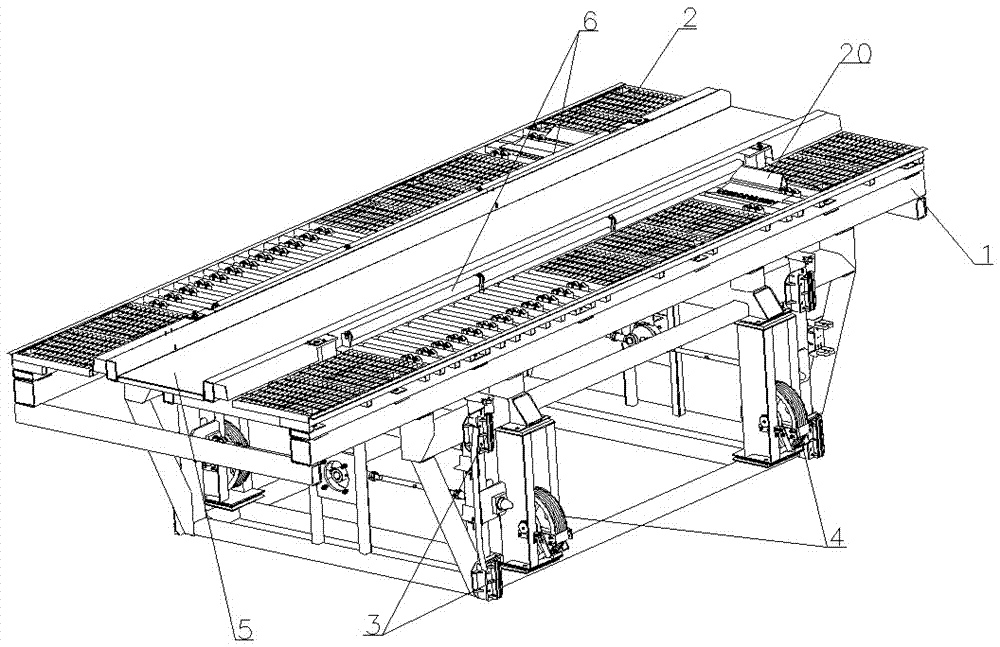

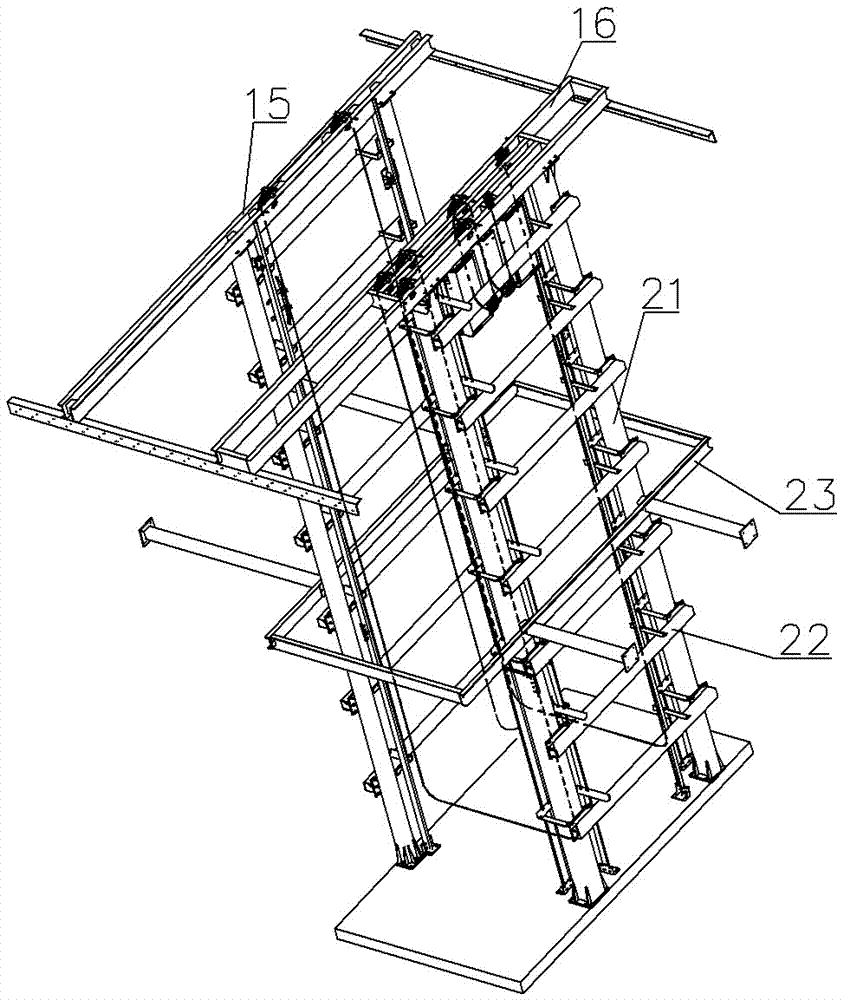

[0024] An embodiment of an elevator-type mechanical garage lifting system, in Figure 1-Figure 5 Among them, the four main rails 14 are located at the four corners of a rectangle, and the four columns 21 are also located at the four corners of a rectangle, wherein the upper ends of two of the columns 21 are fixed with wheel beams A15, and the upper ends of the other two columns 21 are fixed with wheel beams. The beam B16, the wheel beam A15 and the wheel beam B16 are parallel, and a ring beam 23 and a beam 22 are arranged outside the main rail 14 to strengthen the frame formed by the main rail and the wheel beam A and wheel beam B. Two counterweight guide rails 17 are arranged between the two columns used to fix the wheel beam B, and a counterweight 18 is slidably mounted on the counterweight guide rails 17, and a traction rail is fixed on one of the two columns fixing the wheel beam B. machine19. An encoder is installed on the main shaft of the traction machine 19, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com