Low-temperature testing apparatus of injection molding rod material

A low-temperature test and injection molding rod technology, which is applied in the direction of applying a stable bending force to test the strength of materials, can solve the problems of cracks in plastic products and long cooling time of plastic parts, and achieve the effect of preventing deformation and cracking and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

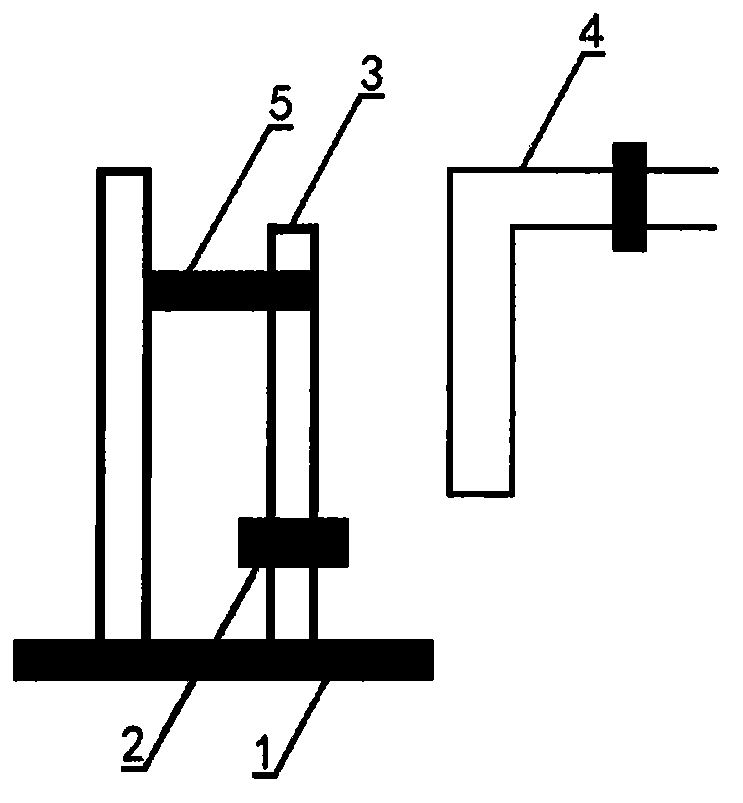

[0012] Embodiment: as shown in the accompanying drawing. A low-temperature testing device for injection-molded rod materials, including a frame [1], a fixed frame [2] is set on the frame, plastic rods [3] can be inserted into the fixed frame, and a low-temperature guide is set on a section of the fixed frame. The air duct [4] and the air duct are connected to the low-temperature air source, and the bending component [5] is set on the upper end of the fixing frame. When in use, place the plastic rod [3] on the fixing frame, start the low temperature, and the bending component [5] fixes the plastic rod The piece [3] was subjected to a low-temperature bending test.

[0013] A low-temperature testing device for injection-molded rod material, in which dense air-guiding holes are arranged on the low-temperature air-guiding pipe [4].

[0014] A low-temperature test device for injection molded rod material, the diameter of the air guide hole should be less than 0.2 mm.

[0015] A lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com