Pipeline ultrasonic guided wave corrosion monitoring device and method

An ultrasonic guided wave and corrosion monitoring technology, which is applied to the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. The effect of efficient monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

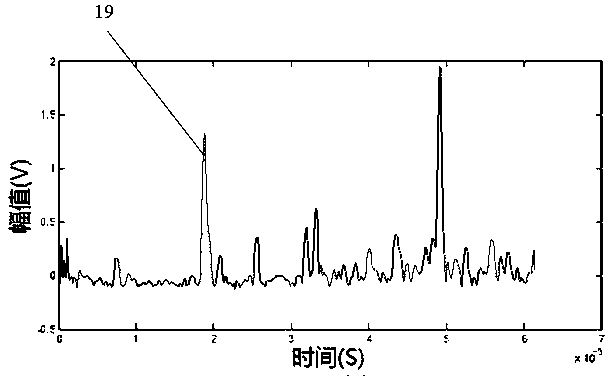

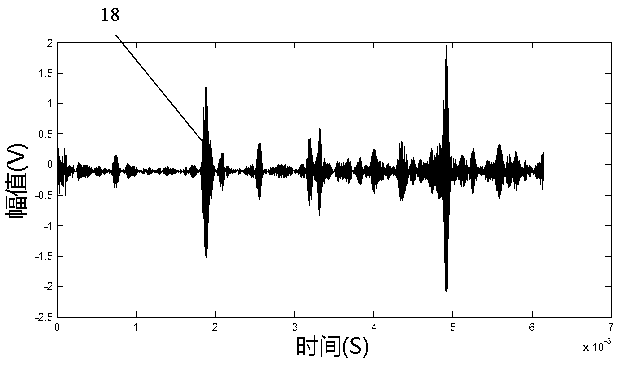

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with drawings and embodiments.

[0060] Embodiments of the present invention and its implementation process are as follows:

[0061] The device of the embodiment of the present invention is as figure 1 shown, including:

[0062] Permanently install the magnetostrictive ultrasonic guided wave transducer 2 on the monitored pipeline 1, and use epoxy glue and silicone structural glue to ensure the sealing of the installation method;

[0063] Connect the ultrasonic guided wave transducer 2 to the current-limiting module 3, and the current-limiting module 3 controls the conduction current, and uses multiple relays to connect multiple power resistors to control the resistance of the load to realize current control;

[0064] Connect the current limiting module 3 to the farad capacitor group 4, and the farad capacitor group 4 transmits the instantaneous large current to the ultrasonic guided wave transducer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com