Electrostatic fan dust collector

A technology of dust collector and electrostatic generator, applied in the direction of external electrostatic separator, electrostatic separation, etc., can solve the problems of decreased air permeability, secondary dust raising, complex shape of electrostatic electrode sheet, etc., and achieves novel structure and efficient adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

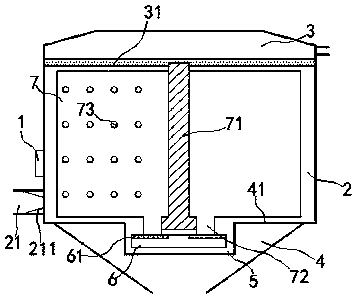

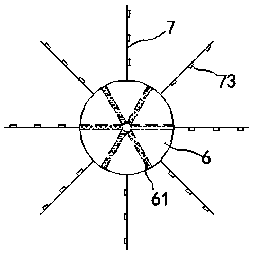

[0014] exist figure 1 , figure 2 In the shown embodiment, the electrostatic fan dust collector includes an electrostatic generator 1, a dust removal chamber 2, a clean chamber 3 and an ash hopper 4; the dust removal chamber 2 and the clean chamber 3 are respectively provided with air inlets 21 and Exhaust port; a discharge sheet 211 is electrically connected to the air inlet 21, and the discharge sheet 211 is electrically connected to the negative electrode of the electrostatic generator 1; a purification screen 31 is separated between the purification chamber 3 and the dust removal chamber 2, There is a dust collection screen 41 between the dust removal chamber 2 and the ash bucket 4; a drive box 5 is fixedly installed in the center of the dust collection screen 41; a power disc 6 is installed in the drive box 5, and The round surface of the disk 6 is equidistantly embedded with conductive sheets 61 in the circumferential direction, and the conductive sheets 61 are insulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com