Five-axis linkage CNC drilling and riveting equipment with ab rotary motion axis double drive mechanism

A five-axis linkage, dual-drive technology, applied in the field of aircraft assembly technology and equipment, can solve the problems of small bearing capacity, inability to meet high bearing capacity, high machining accuracy, etc., to improve bearing capacity, improve safety and reliability, and achieve accurate The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

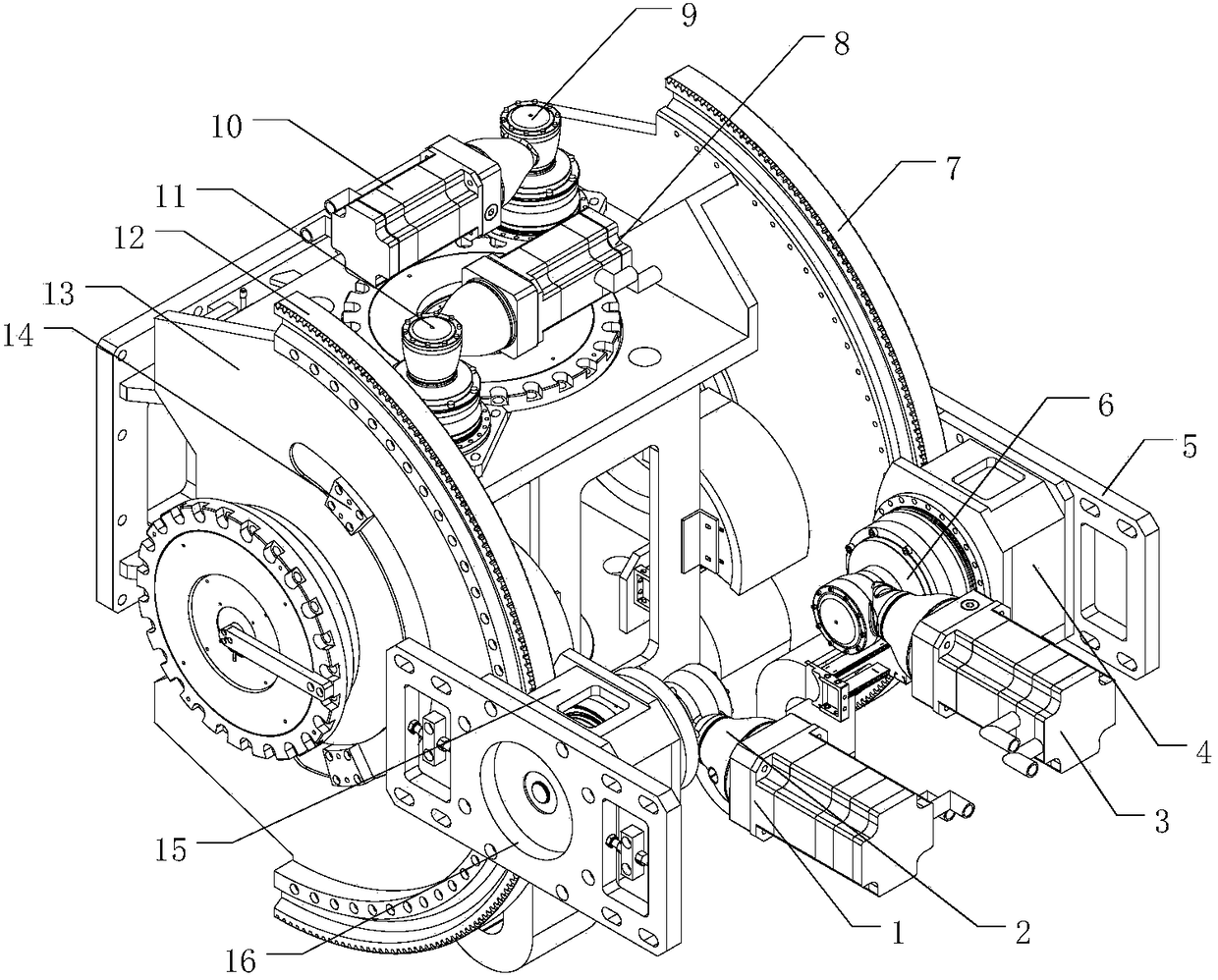

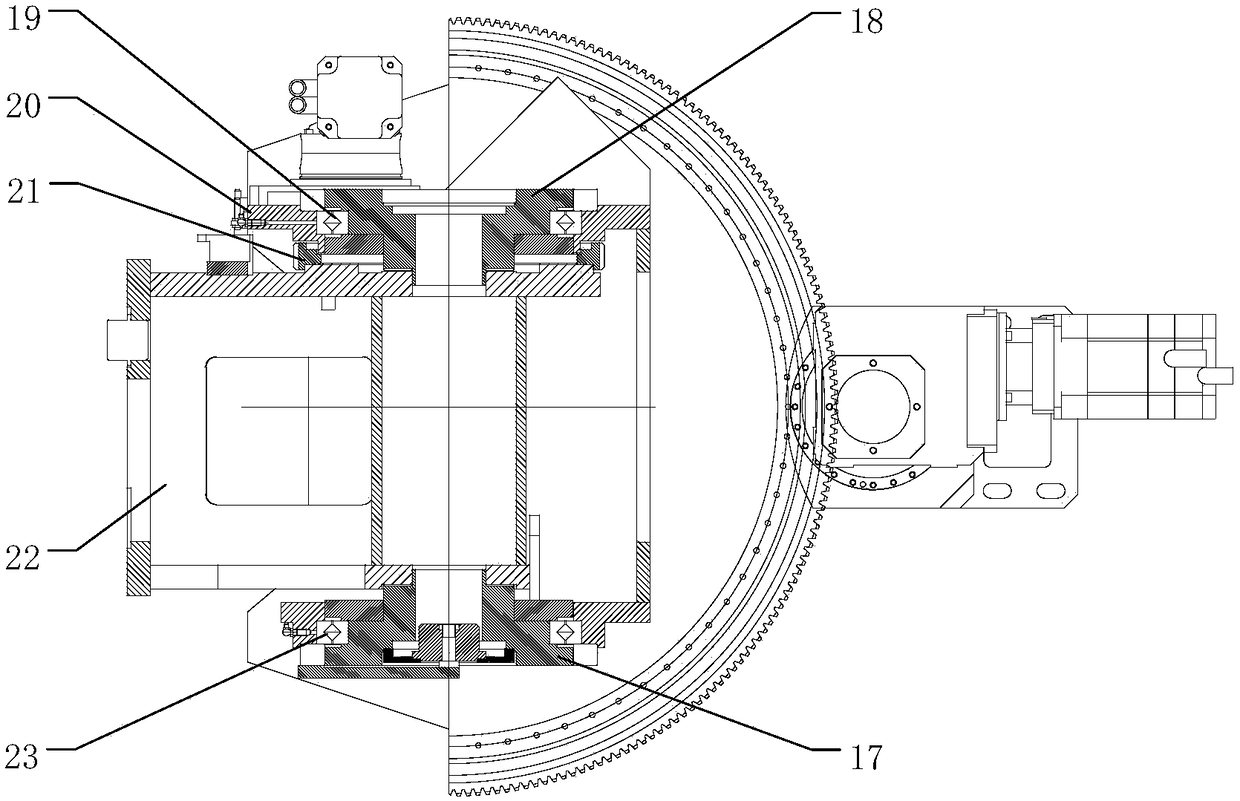

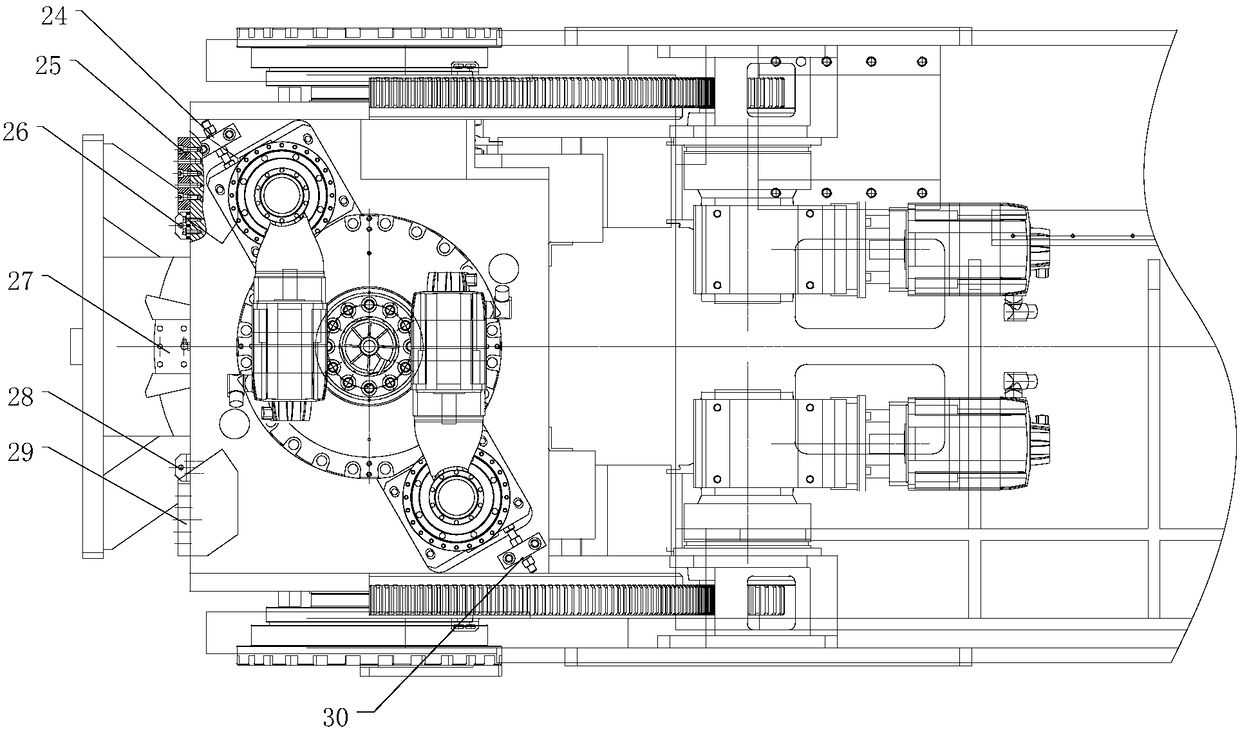

[0033] Such as Figure 1-5 As shown, a five-axis linkage CNC drilling and riveting equipment AB-axis rotary motion dual drive mechanism, the first servo motor 1, the second servo motor 3, the third servo motor 8 and the fourth servo motor 10, the first reducer 2 , the second reducer 6, the third reducer 9 and the fourth reducer 11, the first A-axis reducer mounting seat 4 and the second A-axis reducer mounting seat 15, the first A-axis reducer mounting plate 5 and the first A-axis reducer mounting plate Two A-axis reducer mounting plates 16, the first A-axis large gear 7 and the second A-axis large gear 12, the A-axis rotary seat 13, the rotary stroke block 14, the first B-axis driving end rotary bearing assembly 17 and the second B-axis driving end slewing bearing assembly 18, first rolling bearing 19 and second rolling bearing 23, joint type pressure oiling cup 20, B-axis large gear 21, B-axis slewing seat 22, first tensioning block 24 and second tensioning block 30. The fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap