A handling robot mechanical claw

A technology for handling robots and mechanical claws. It is applied in the field of handling robot mechanical claws and robots. It can solve the problems of reducing production efficiency, wasting replacement time, and fixing them, and achieves the effects of reducing production costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

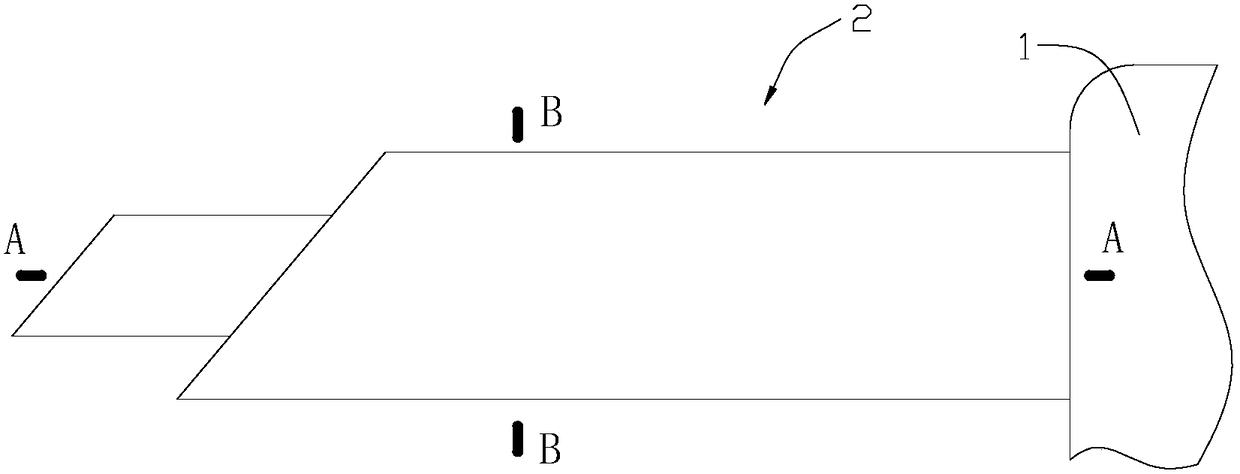

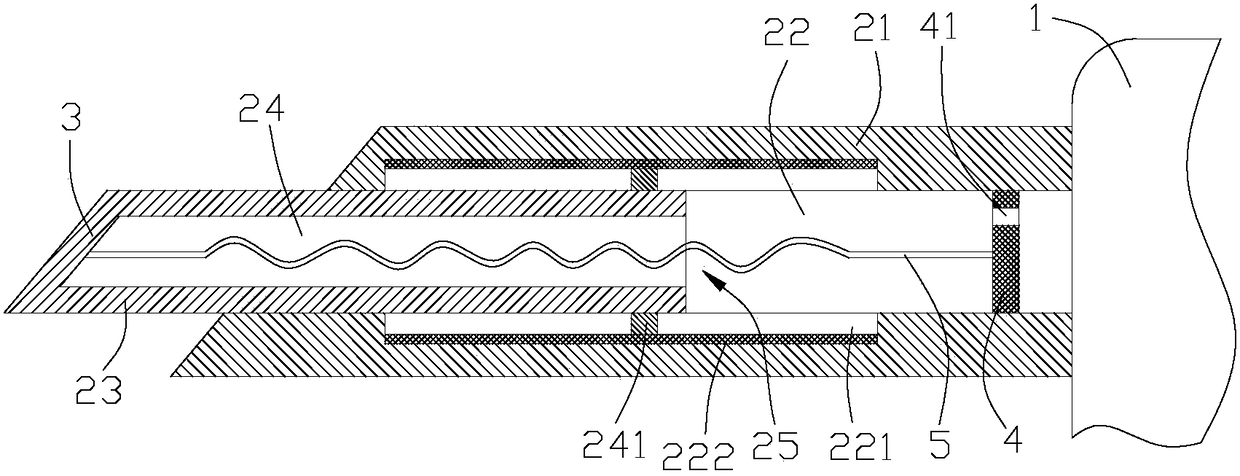

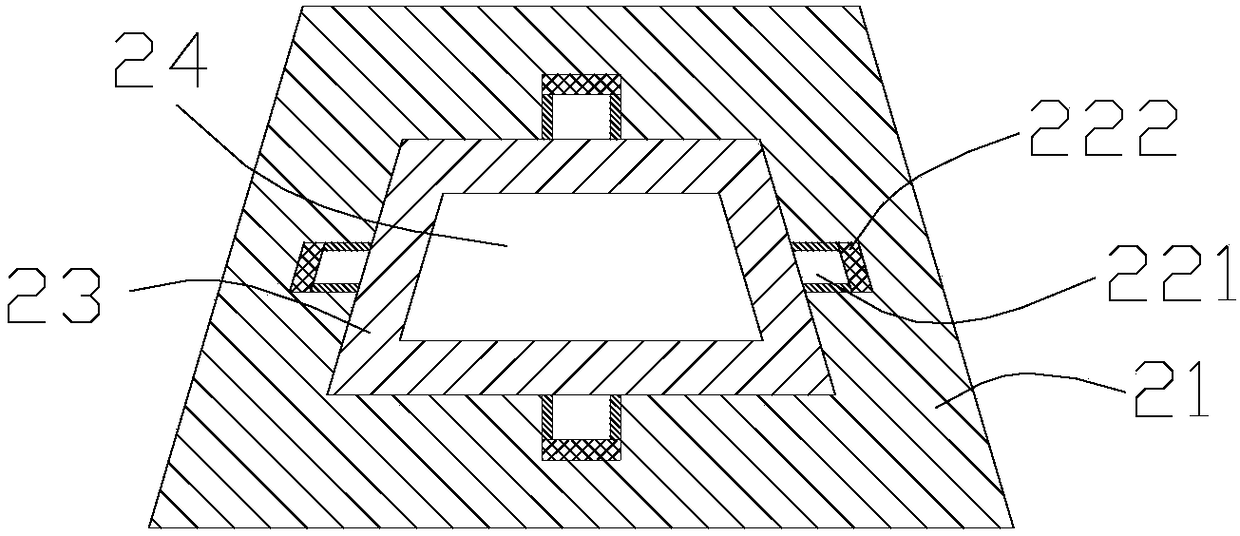

[0015] Combine below figure 1 , 2 and 3 describe the invention in detail:

[0016] A mechanical claw of a handling robot, including a claw body 2 hinged with a robot forearm 1, the claw body can be driven to swing by the forearm, and can also be driven to bend by a driving mechanism; the claw body 2 of the present invention includes a hollow outer claw 21 and is arranged on The outer jaw inner cavity 22 and the front end are closed by the cover plate 3 and the hollow inner jaw 23. The outer jaw inner cavity 22 and the inner jaw inner cavity 24 form a closed cavity 25, and the inner jaw passes through the inner jaw cavity in the sealed cavity. The air pressure can extend or retract the inner cavity of the outer claw, so as to realize the replacement of the thickness of the mechanical claw.

[0017] In the present invention, the rear end of the inner cavity of the outer claw is fixedly provided with a baffle 4 covering the inner cavity, the inner claw is located at the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com