Manipulator for transport robot for producing automobiles

A technology for handling robots and mechanical arms, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of reducing production efficiency, wasting replacement time, increasing production costs, etc., and achieving the effect of reducing production costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

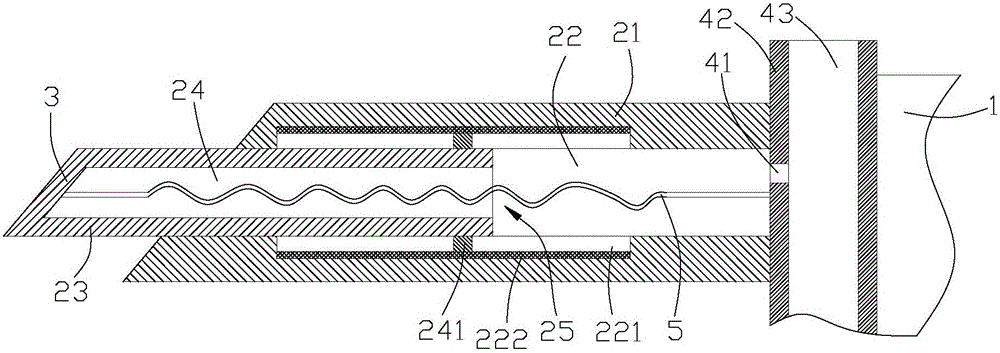

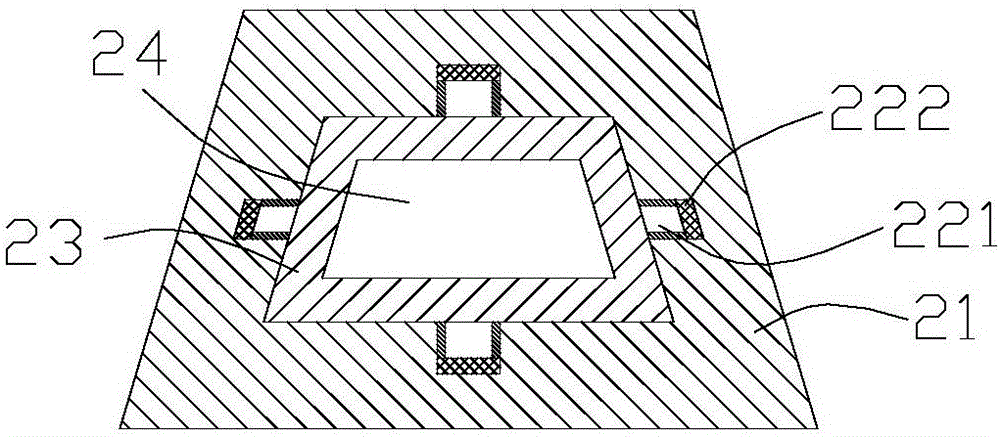

[0015] Combine below figure 1 , 2 And 3 introduce the invention in detail:

[0016] The mechanical arm of a handling robot for automobile production includes a robot arm 1 and several mechanical claws 2. Each mechanical claw is hinged with the forearm through a wrist 4, and the wrist includes a rotatable hollow rotary shaft 42. The rotary shaft One side in the radial direction is fixedly connected to each of the mechanical claws, and the other side in the radial direction of the rotating shaft is hinged with the small arm. By driving the rotating shaft to rotate, the mechanical claw can be driven to rotate, and the mechanical claw can be driven by the swing of the small arm. Swing; The mechanical claw is a hollow mechanical claw, and the high-pressure gas flowing through the inner cavity 43 of the rotating shaft and the cavity 25 of the mechanical claw drives the mechanical claw to expand or contract, so as to realize the thickness change of the mechanical claw.

[0017] The mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com