injection molding machine

A technology for injection molding machines and molding materials, applied in the field of injection molding machines, can solve problems such as large filling volume deviations and large quality deviations of molded products, and achieve the effect of reducing quality deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the manners for implementing the present invention will be described with reference to the accompanying drawings. The same or corresponding structures are denoted by the same or corresponding symbols in the respective drawings, and the description will be omitted.

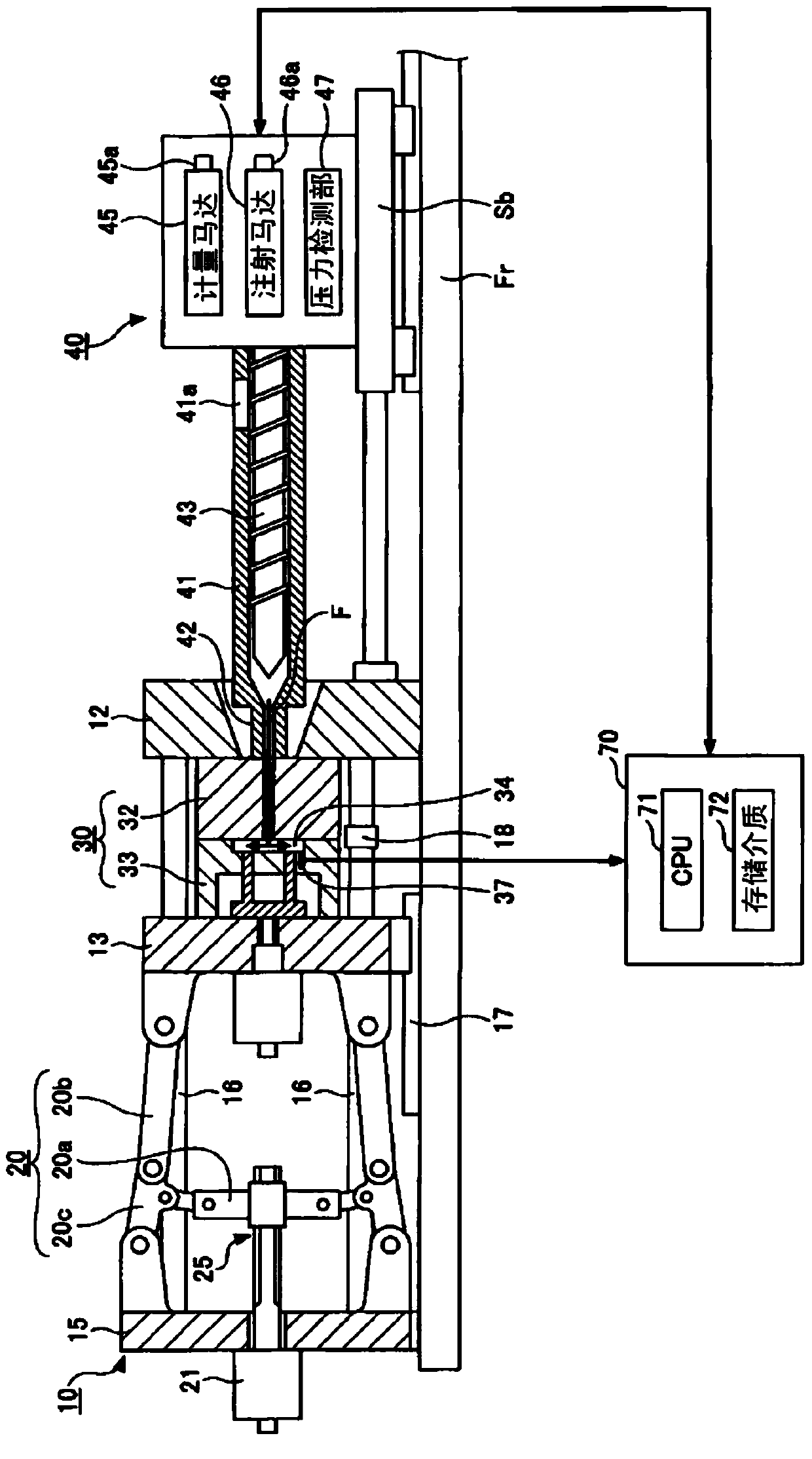

[0014] figure 1 This is a diagram showing an injection molding machine according to an embodiment of the present invention. figure 1 The middle arrow F indicates the flow of the molding material. figure 1 The illustrated injection molding machine has a frame Fr, a mold clamping device 10, an injection device 40, a controller 70, and the like. The controller 70 has a CPU (Central Processing Unit) 71 and a storage medium 72 such as a memory. The controller 70 causes the CPU 71 to execute a program stored in the storage medium 72 to thereby control the mold clamping device 10 and the injection device 40.

[0015] Next, the mold clamping device 10 will be described. In the description of the mold clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com