Embroidery machine and correction method thereof

A calibration method and technology for embroidery machines, applied in the direction of embroidery machines, embroidery machine mechanisms, and automatically controlled embroidery machines, can solve problems such as embroidery quality problems and embroidery quality effects, reduce quality deviation, improve embroidery machine quality, The effect of excellent embroidery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

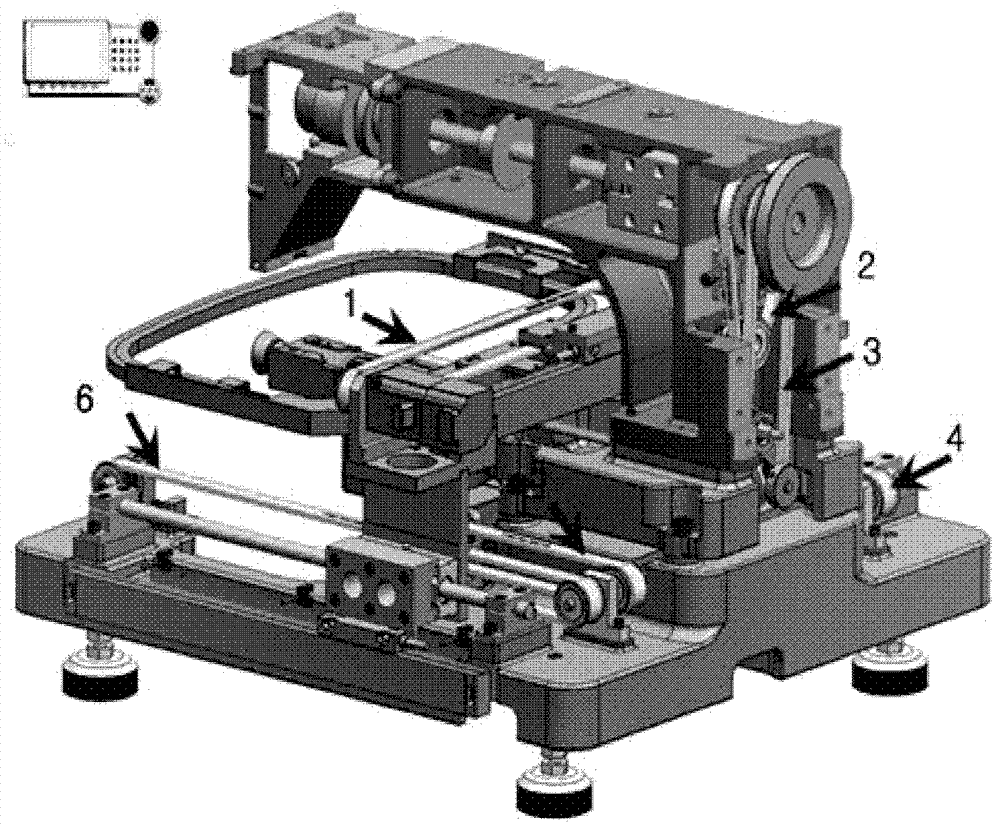

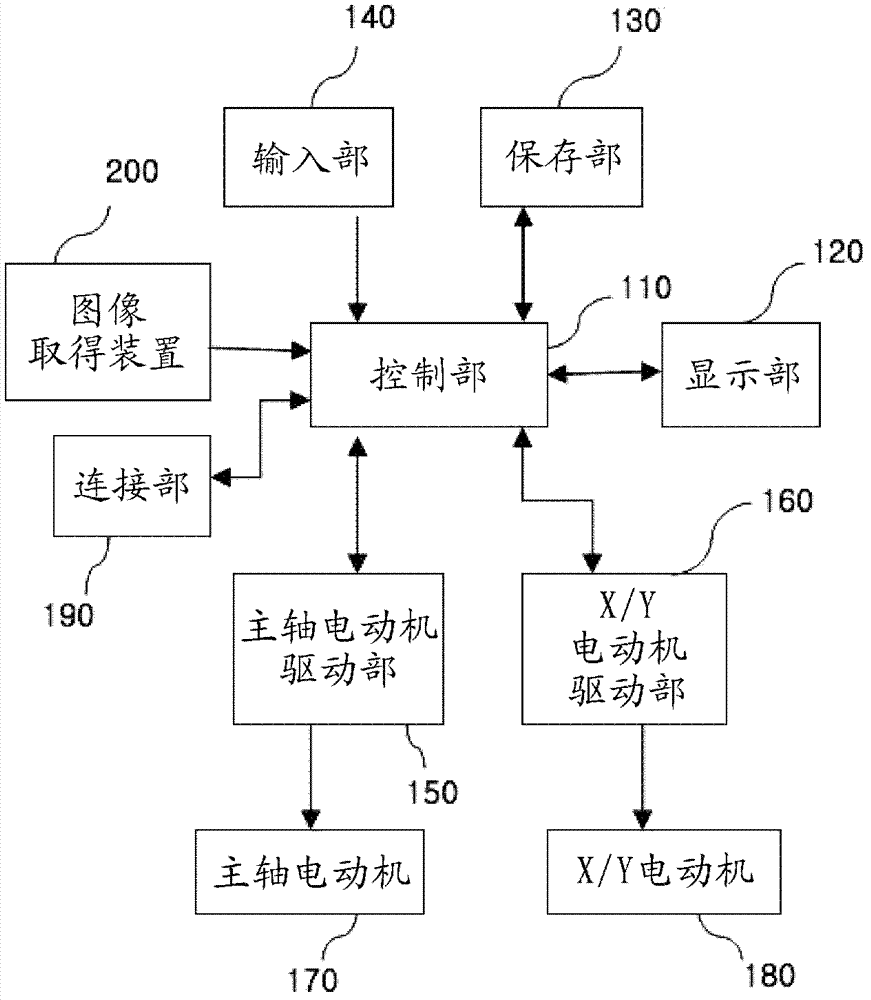

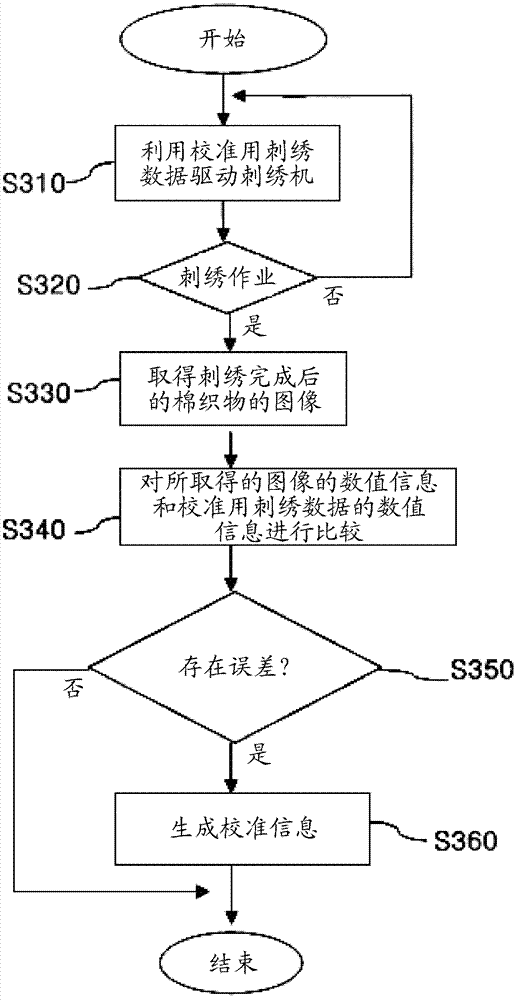

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings so that those who have ordinary knowledge in the technical field to which the present invention pertains can easily carry out. However, the present invention can be implemented in various forms and is not limited to the embodiments described here. In addition, in the drawings, parts irrelevant to the description for clearly explaining the present invention are omitted, and similar reference numerals are attached to similar parts throughout the specification.

[0034] In the entire specification, when a certain part "includes" a certain structural element, as long as there is no contrary statement, it means that other structural elements can be included, and other structural elements are not excluded.

[0035] In the embodiment of the present invention, the device referred to as an embroidery machine is not limited to an embroidery machine, but includes all device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com