Empty packing and condom pressing automatic detecting device and detecting method in condom sealed packing process

An automatic detection device and sealing packaging technology, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of pinholes in products, difficulty for users to detect, and difficulty in reducing unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

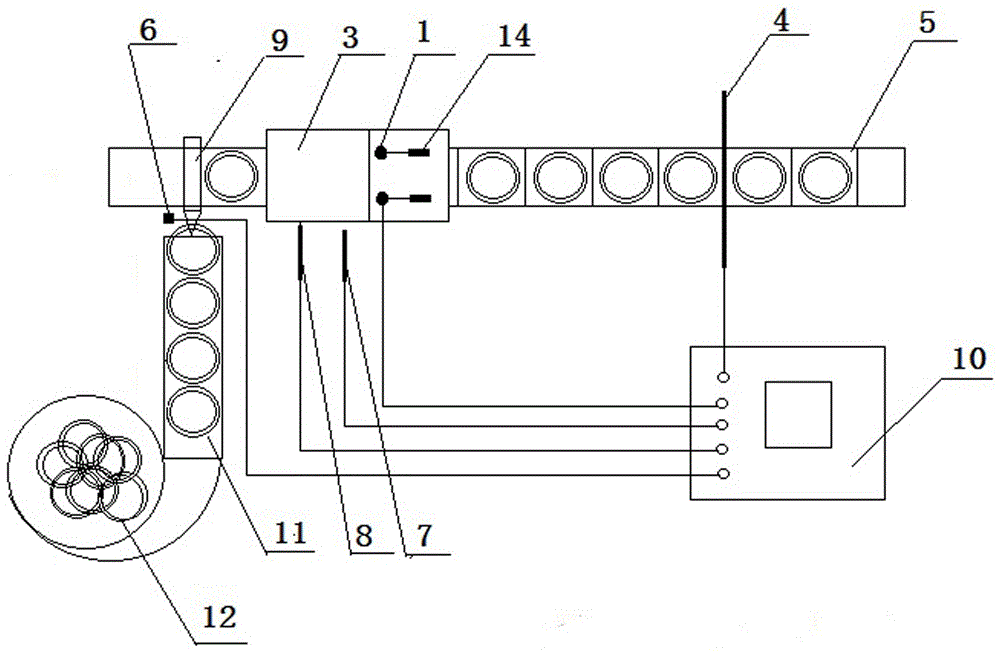

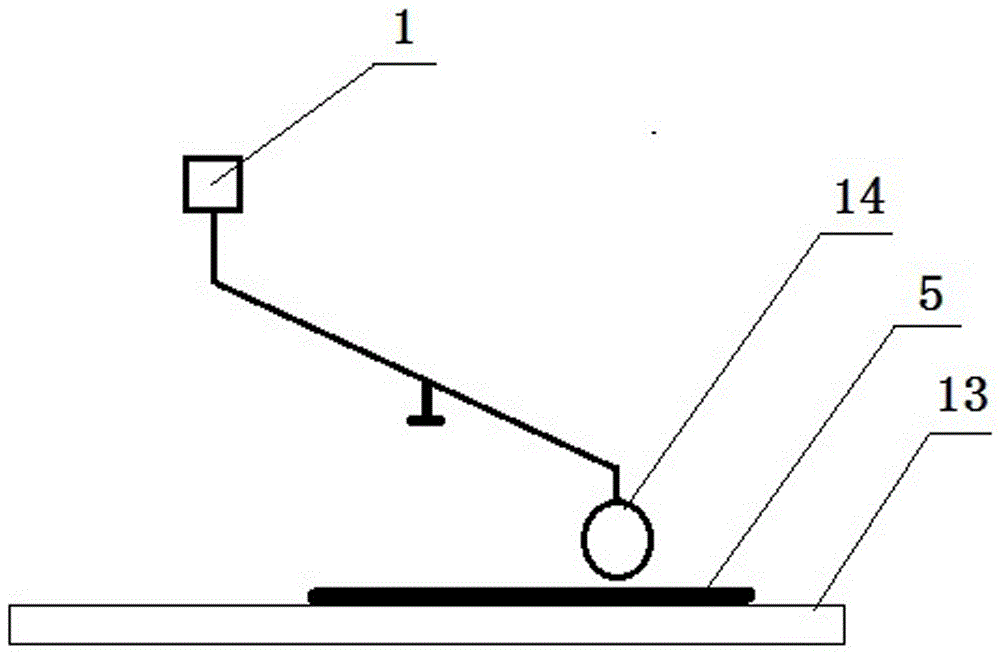

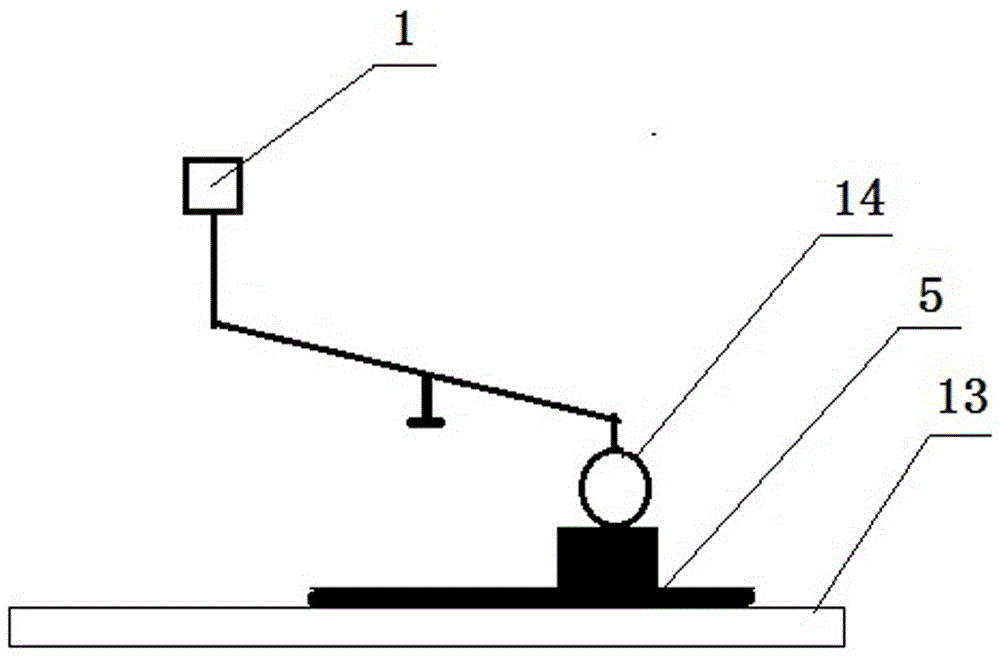

[0018] Aiming at the above-mentioned technical solution, a preferred embodiment is given and described in detail with reference to the drawings. The automatic detection device for the empty bag pressing sleeve of the condom in the sealing and packaging process of the present invention mainly includes an upper sleeve track, a sealing track, a sealing mold, an empty bag sensor, a pressing sleeve sensor, a synchronous sensor, a pressing sleeve detection device, and a cutter. Figure 1 to Figure 3 ,in.

[0019] A vibrating upper casing 12 and an upper casing track 11 connected with the vibration upper casing are installed on the frame, and an enveloping track 13 is arranged on one side of the upper casing track. An encapsulation mold 3 is installed on one side of the upper cover track on the encapsulation track. Two wrapping film rolls are arranged on one side of the wrapping mold, and a cutter 4 is arranged on the wrapping track on the other side thereof, and the cutter is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com