Hard-coat infused polycarbonate headlamp lens and related method

A polycarbonate, headlight technology, applied in coatings, lenses, headlights, etc., can solve problems such as reducing headlight performance, lens impact performance degradation, and accelerating matrix degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

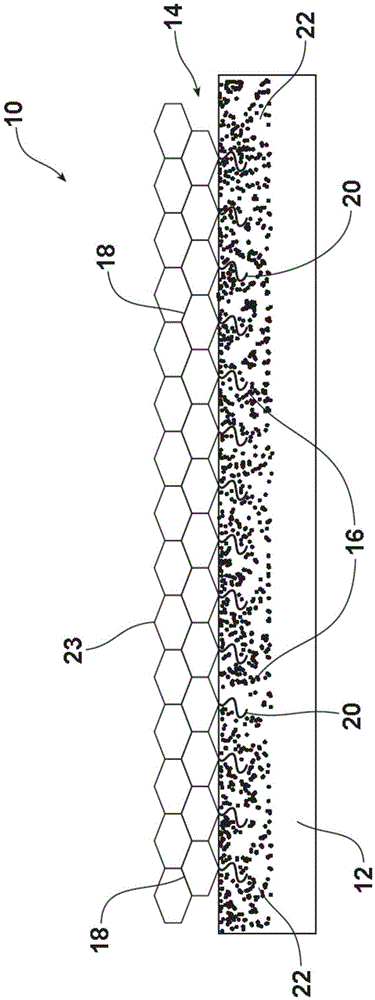

[0017] Referring now to the description of the headlight lens 10 figure 1 . The headlamp lens 10 comprises a polycarbonate base 12 and an impregnated protective outer layer 14 covering at least one surface (i.e., the front surface) of the polycarbonate base and optionally a PECVD (Plasma Enhanced Chemical Vapor Deposition) composition. .

[0018] In one embodiment, the impregnated protective outer layer 14 includes an anti-scratch agent and a UV inhibitor. In one possible embodiment, the anti-scratch agent is polysiloxane based. Such anti-scratch agents may be selected from the group consisting of vinyl (mono-, di- and tri-alkoxysilanes), phenyl (mono-, di- and tri-alkoxysilanes), biphenylbis Alkoxysilane, Vinyltrimethoxysilane, and other polysiloxane-based molecules and mixtures thereof.

[0019] In one embodiment, the UV inhibitor is selected from the group consisting of benzophenones, benzotriazoles, or other compounds like hydroxyphenyltriazines, and mixtures thereof. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com