Main shaft inclined plate of variable-displacement compressor

A compressor and variable displacement technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., to reduce transmission friction, ensure flatness, and increase working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

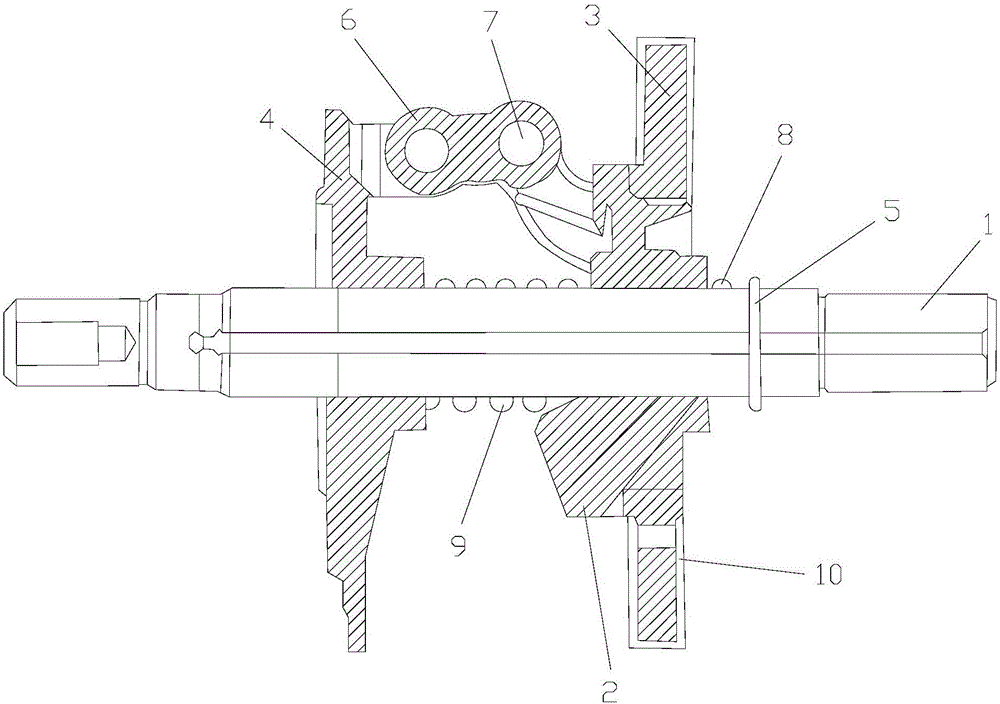

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Referring to the accompanying drawings: the main shaft swash plate of the variable displacement compressor in this embodiment includes a main shaft 1, a swash plate seat 2 is installed on the main shaft 1, a swash plate 3 is installed on the swash plate seat 2, and a part of the swash plate 3 There is a rotating arm 4 on one side, and a spindle snap ring 5 is provided on the other side of the swash plate 3. The rotating arm 4 is installed on the main shaft 1, and the connecting plate 6 is connected between the rotating arm 4 and the swash plate 3, and the connecting plate 6 passes through The connecting plate pin 7 is respectively connected to the rotating arm 4 and the swash plate seat 2, and the return spring 1 8 is arranged between the main shaft snap ring 5 and the swash plate 2. Two return springs 9 are arranged between them, and the two return springs 9 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com