Structure for reducing flexibility deformation of inner metal pipe of solar moderate-high-temperature heat collection tube

A technology of medium and high temperature heat collecting tubes and metal inner tubes, which is applied in the field of emerging energy and solar energy, can solve the problems of reducing light concentration ratio, reducing heat collection efficiency, and reducing overall absorption rate, so as to reduce bending deformation and ensure heat collection efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

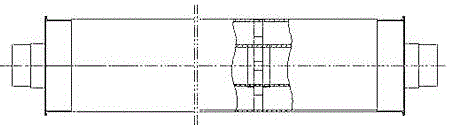

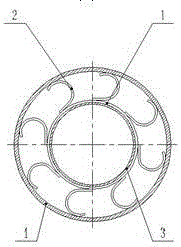

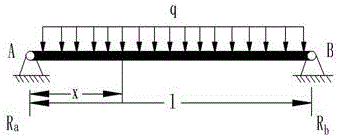

[0017] Refer to attached figure 1 And attached figure 2 , a structure for reducing deflection and deformation of a metal inner tube of a solar energy medium and high temperature heat collector tube. At least one support device is provided between the metal inner tube of the heat collector tube and the glass outer tube, and the support device includes a ferrule ring 1 and a plurality of elastic supports 2. The associated ferrule ring 1 is coaxial with the metal inner tube 3 and fixed on the metal inner tube 3. The elastic support 2 is supported on the inner wall of the glass outer tube 4. The ferrule ring 1 and the elastic support 2 connected, the support device is located in the middle of the heat collecting tube along the axial length direction, the heat collecting tube is fixed at both ends, and the fixing frame has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com