Support for fixing heat collector on built roof

A heat collector and support foot technology, applied in the field of solar energy, can solve the problems of unsightly, easy to damage the roof, and difficult to adjust the height, etc., to achieve the effects of stable water flow, saving time, and ensuring heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

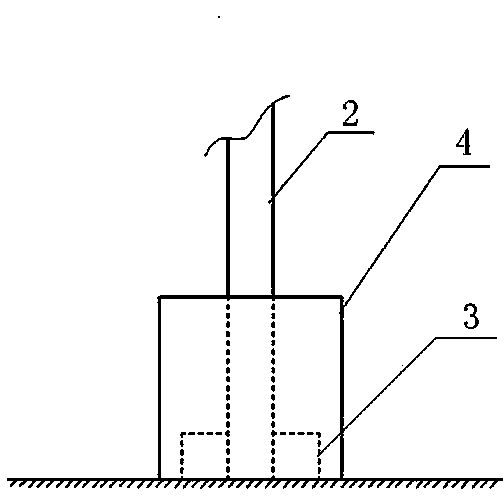

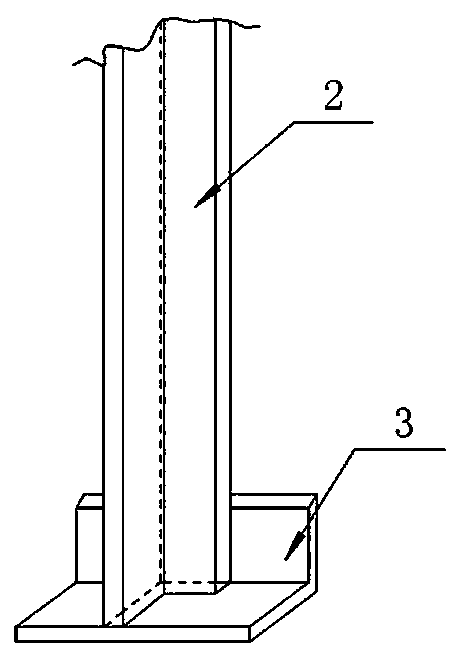

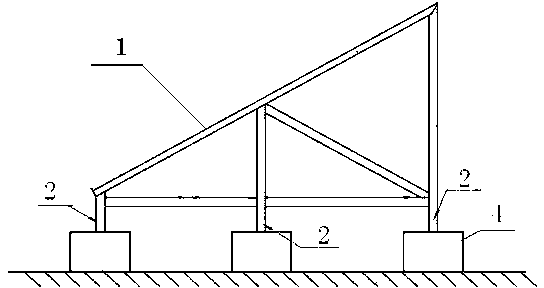

[0018] like Figure 1-3 As shown, the present invention comprises a bracket body 1, and the bracket body 1 is provided with a plurality of bracket feet 2, and is characterized in that: the bottom of the bracket feet 2 is welded with a fixed block 3, and the bracket feet 2 are covered with a hollow fixed column 4, and the fixed column 4 and Cement is poured between the support feet 2.

[0019] The fixing block 3 is hot-dip galvanized angle steel, and the length of the fixing block 3 is smaller than the inner diameter of the fixing column 4 .

[0020] The fixed column is a PVC pipe.

[0021] When installing a fixed heat collector bracket on the built roof, first put a fixed column 4 on the periphery of the bracket foot of the bracket body 1. The fixed column 4 is a hollow PVC pipe with an outer diameter of 160mm and a height of 160mm; then the bracket body 1 is erected on the On the roof, perform flatness correction; after the correction is completed, weld the fixed block 3 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com