Pulse pre-pumping single-ended vector botda dynamic strain measurement method and device

A dynamic strain and measurement method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that SBS strength is seriously affected by non-local effects, inconvenient application, low reliability, etc., to achieve spatial resolution and Good measurement accuracy, improved SBS action efficiency, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

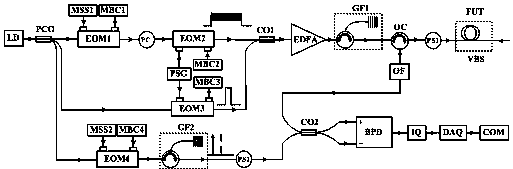

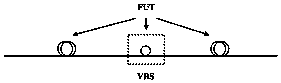

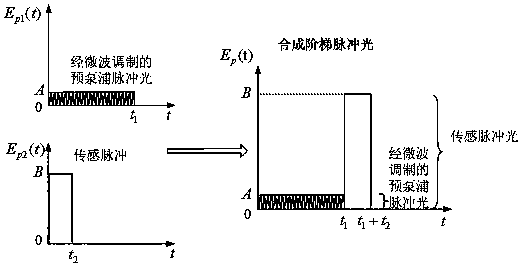

[0032] Referring to Fig. 1, the measurement device of the present invention includes a narrow linewidth laser LD, a polarization maintaining coupler PCO, a first microwave signal source MSS1, a first bias voltage controller MBC1, a first electro-optic modulator EOM1, a polarization controller PC, a pulse Signal source PSG, second bias controller MBC2, second electro-optic modulator EOM2, third bias controller MBC3, third electro-optic modulator EOM3, second microwave signal source MSS2, fourth bias controller MBC4, first Four electro-optic modulators EOM4, second grating filter GF2, first coupler CO1, erbium-doped fiber amplifier EDFA, first grating filter GF1, optical circulator OC, first polarization scrambler PS1, sensing fiber FUT, vibration Source VBS, optical filter OF, second polarization scrambler PS2, second coupler CO2, balanced detector BPD, quadrature phase demo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com