Elastic force detection device for automobile clutch coil group

A clutch spring and detection device technology, applied in the field of fixtures, can solve the problems of affecting the detection results, easy error accumulation, unintuitive and accurate detection, etc., and achieve the effect of accurate measurement results and precise pressing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

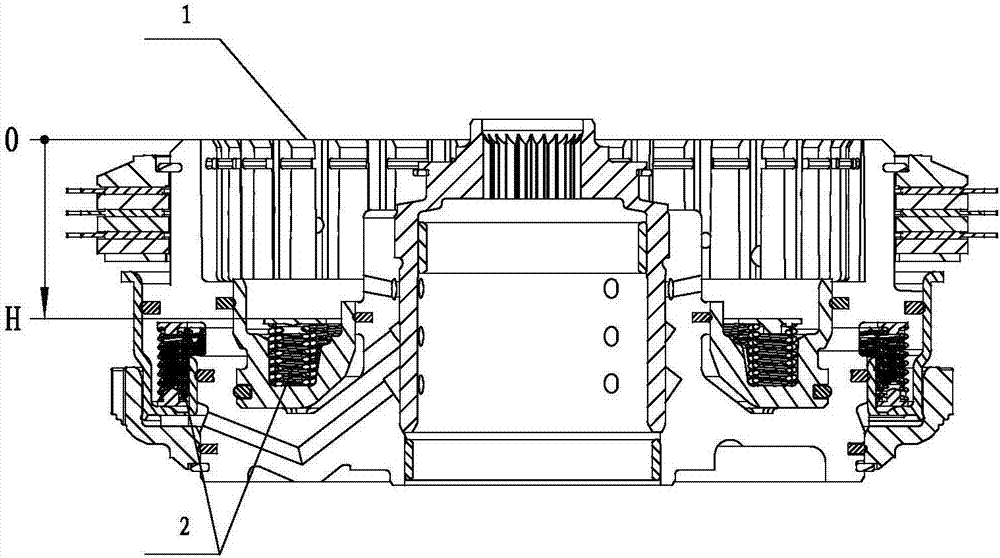

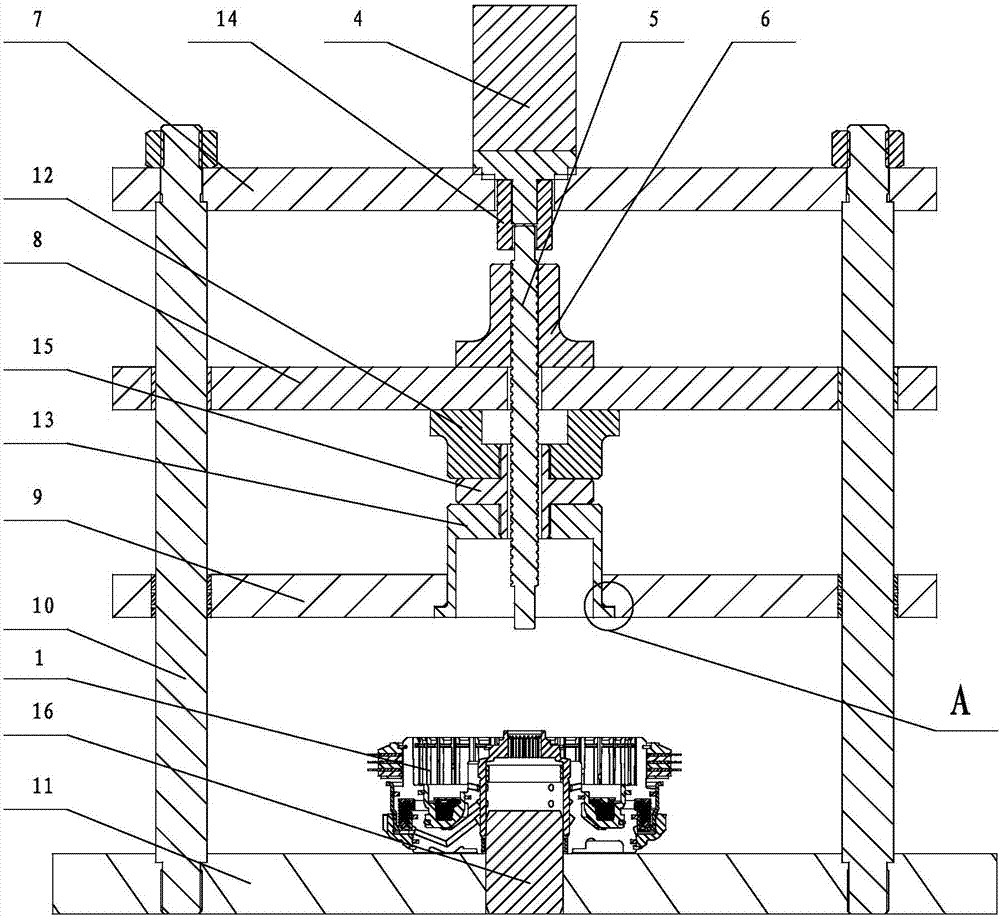

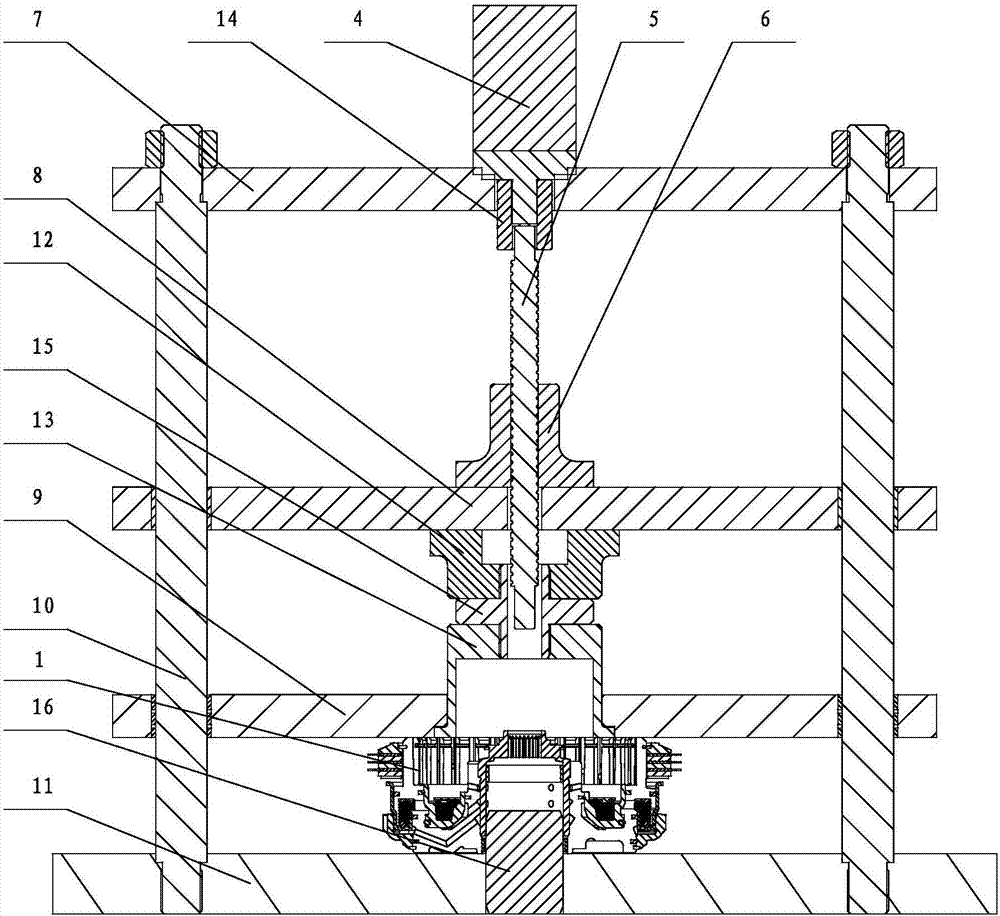

[0042] Depend on Figure 2 to Figure 8 It can be seen from the structural schematic diagram of the first structure of the elastic force detection device of the automobile clutch spring coil group shown in the present invention that the number of the support assembly is one, and the support assembly includes a movable support and a fixed support. The movable support is slidingly connected on the fixed support. The driving device is a driving motor 4, which is installed on the top of the fixed support, and the output shaft of the driving motor 4 is connected with the movable support through a transmission mechanism; above.

[0043] The fixed support includes a first column 10 and a first top plate 7; the number of the first column 10 is two, which are respectively located on both sides of the automobile clutch 1, and the lower end of the first column 10 is screwed on the bottom plate 11 and passed through The shaft shoulder is positioned, the upper end passes through the first...

specific Embodiment 2

[0052] Depend on Figure 9 ~ Figure 12 It can be seen from the structural schematic diagram of the second structure of the elastic force detection device of the automobile clutch spring coil group shown in the present invention that the number of the support assemblies is two, and the first work of elastic force measurement is carried out at two stations respectively. Position measuring device 19 and second position measuring device 18. The positioning device on which the automobile clutch 1 is placed is a mobile workbench, which slides on the base plate 11 through a pulling device and performs elastic force measurement at the positions of the first station measuring device 19 and the second station measuring device 18 respectively. The first station measuring device 19 and the second station measuring device 18 are all connected with the press-in assembly with the pressure sensor 15 having the same structure, and the first station measuring device 19 and the second station me...

specific Embodiment 3

[0063] Depend on Figure 13 As shown in the elastic detection device of the automobile clutch spring coil group of the present invention, the number of the support assembly is one, and the support assembly includes a movable support and a fixed support, and the movable support is slidably connected to the fixed support. superior. The driving device is a driving motor 4, the driving motor 4 is installed on the movable support, the transmission mechanism is a screw nut structure, the transmission nut 6 is fixedly connected to the top of the fixed support, and the upper end of the transmission screw 5 is engaged with the transmission nut 6 for transmission. , the lower end is connected with the output shaft of the drive motor 4. The pressure device is connected to the lower end of the movable support and is located above the coil group 2 . It also includes a distance measuring sensor 35, which is vertically installed on the support assembly, and the sensing end of the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com