Circuit board fault detection system

A fault detection and circuit board technology, applied in the direction of electronic circuit testing, non-contact circuit testing, etc., can solve the problems of low detection efficiency, achieve high detection efficiency, solve low detection efficiency, and reasonable system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

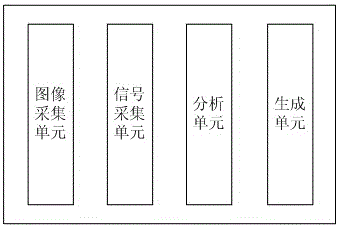

[0025] In Embodiment 1, a circuit board fault detection system is provided, please refer to figure 1 , the system includes:

[0026] An image acquisition unit, the image acquisition unit is used to acquire image information on the surface of the circuit board;

[0027] A signal acquisition unit, the signal acquisition unit is used to collect circuit board signal information;

[0028] An analysis unit, configured to analyze the fault of the circuit board based on the image information and the signal information, and obtain analysis data;

[0029] A generating unit, configured to generate a detection report based on the analysis data.

[0030] Wherein, in the embodiment of the present application, the system further includes a maintenance unit configured to generate a maintenance plan based on the analysis data, and to repair the faulty circuit board based on the maintenance plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com