Endoscope

A technology for endoscopes and operating parts, applied in the field of endoscopes, can solve problems such as user fatigue, increased operating force of operating parts, difficult to bend operation, etc., and achieve the effect of reducing operating force and suppressing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0045] First, a first embodiment of the present invention will be described.

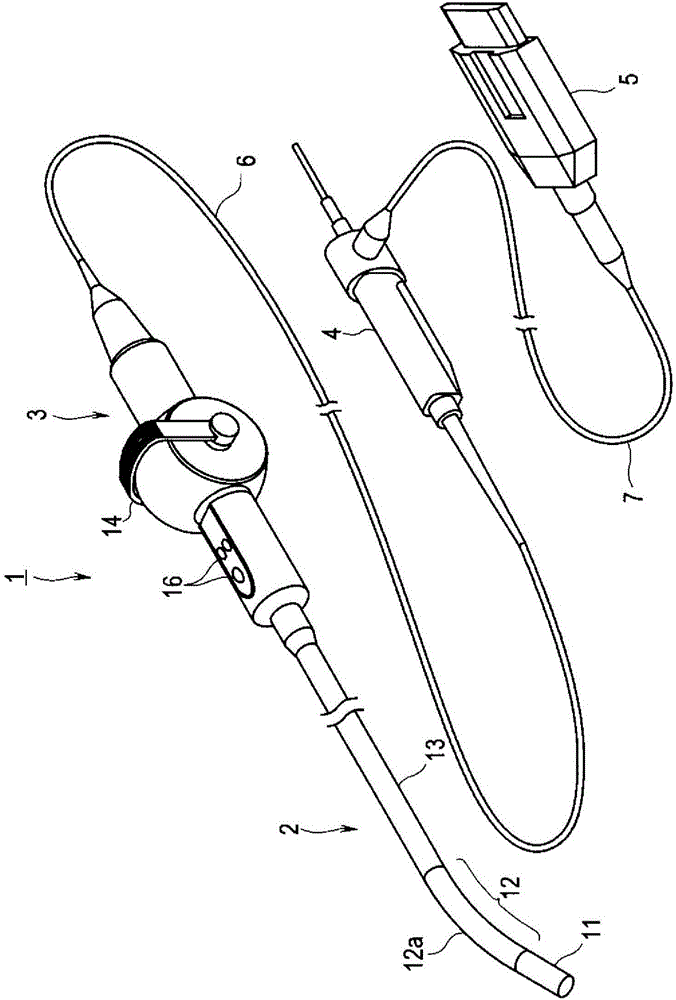

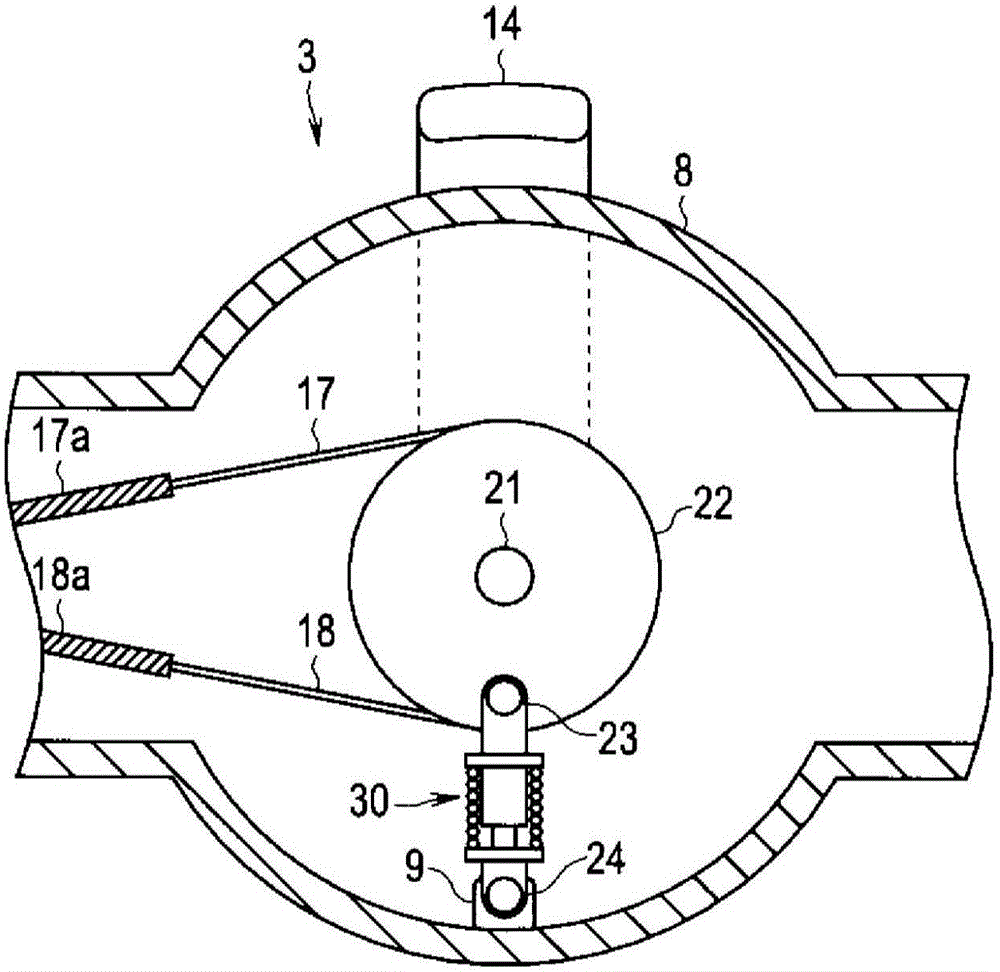

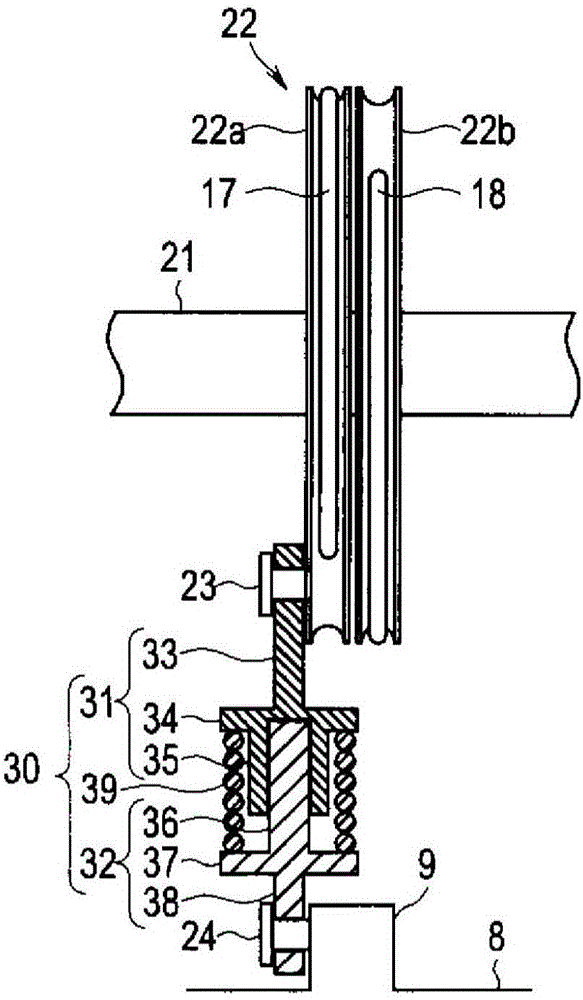

[0046] Figure 1 to Figure 13 Regarding the first embodiment of the present invention, figure 1 is a perspective view showing the overall structure of an endoscope, figure 2 is a cross-sectional view showing the internal structure of the operation unit, image 3 It is a partial cross-sectional view showing the structure of the pulley unit and the operation force reduction part provided in the operation part, Figure 4 It is a figure explaining the action of the operation force reducing part in the state where the bending part is bent toward the upper side, Figure 5It is a figure explaining the function of the operation force reduction part in the state which made the bending part bend toward the lower part side, Image 6 It is a partial sectional view explaining the function of the operation force reduction part in the state where the bending part is bent toward the upper side, Figure 7 It i...

no. 2 Embodiment approach

[0113] Next, a second embodiment of the present invention will be described.

[0114] In addition, in the following description, the same code|symbol is used for the common structural element described in the said 1st Embodiment, and the detailed description of these structural elements is abbreviate|omitted.

[0115] in addition, Figure 14 to Figure 28 Regarding the second embodiment of the present invention, Figure 14 is a plan view showing the structure of an endoscope, Figure 15 is a cross-sectional view showing the internal structure of the operation unit, Figure 16 is a perspective view showing the internal structure of the operation unit, Figure 17 is a cross-sectional view showing the arrangement of tension springs in the operation unit, Figure 18 It is a cross-sectional view showing a tension spring whose one end is hooked to a spring hooking member through which a bending operation wire is inserted, and the other end is hooked to a protrusion of a frame por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com