Xylylenediamine composition and method for producing polyamide resin

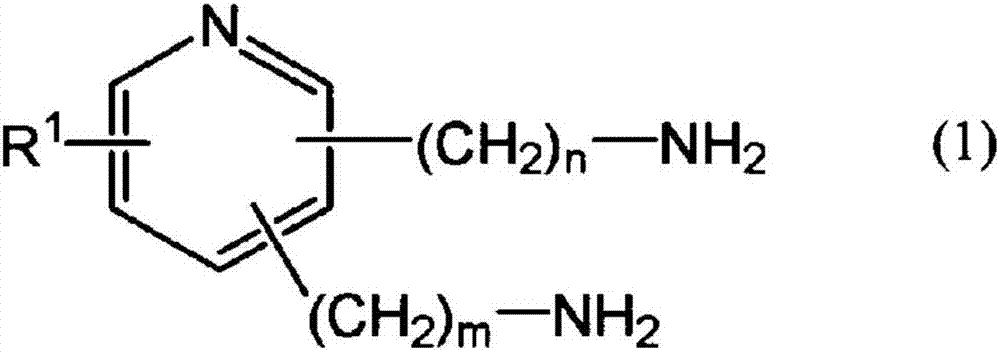

A technology of polyamide resin and xylylenediamine, which is applied in the field of manufacture of xylylenediamine composition and polyamide resin, can solve problems such as mechanical properties and transparency reduction, and achieve improved molding processability, high transparency, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these. In addition, in this Example, various measurements were performed by the following methods.

[0106]

[0107] Accurately weigh 0.2 g of polyamide resin, stir and dissolve in 20 ml of 96% sulfuric acid at 20-30°C. After complete dissolution, quickly take out 5 ml of the solution to a Cannon-Fenske type viscometer, and place it in a constant temperature bath at 25° C. for 10 minutes, then measure the falling time (t). In addition, the falling time (t) of 96% sulfuric acid itself was also measured in the same manner. 0 ). by t and t 0 The relative viscosity was calculated according to the following formula.

[0108]Relative viscosity = t / t 0

[0109]

[0110] Regarding the number average molecular weight of the polyamide resin, first, a sample was dissolved in a phenol / ethanol mixed solvent and a benzyl alcohol solvent, and the carboxyl end group c...

manufacture example 1

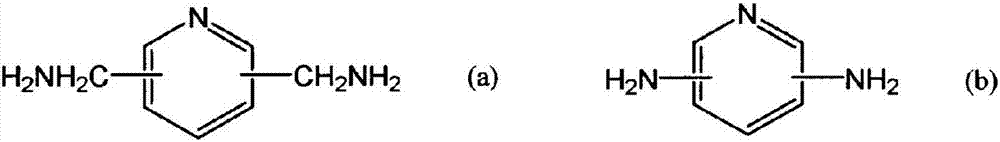

[0123] Production Example 1 (production of 2,6-bis(aminomethyl)pyridine)

[0124] Into a 100 mL autoclave, 2,6-bis(chloromethyl)pyridine / methanol / ammonia=1 / 25 / 100 mol% was charged at a ratio of 2,6-bis(chloromethyl)pyridine / methanol / ammonia=1 / 25 / 100 mol%, and the reaction was carried out at a pressure of 2 MPaG and a temperature of 60° C. for 2 hours. After the reaction, the precipitate was recovered by filtration, an aqueous sodium hydroxide solution was added to the recovered product, and then extracted with toluene, and the solvent was distilled off by a decompression evaporator to obtain 2,6-bis(aminomethyl)pyridine (purity 99%).

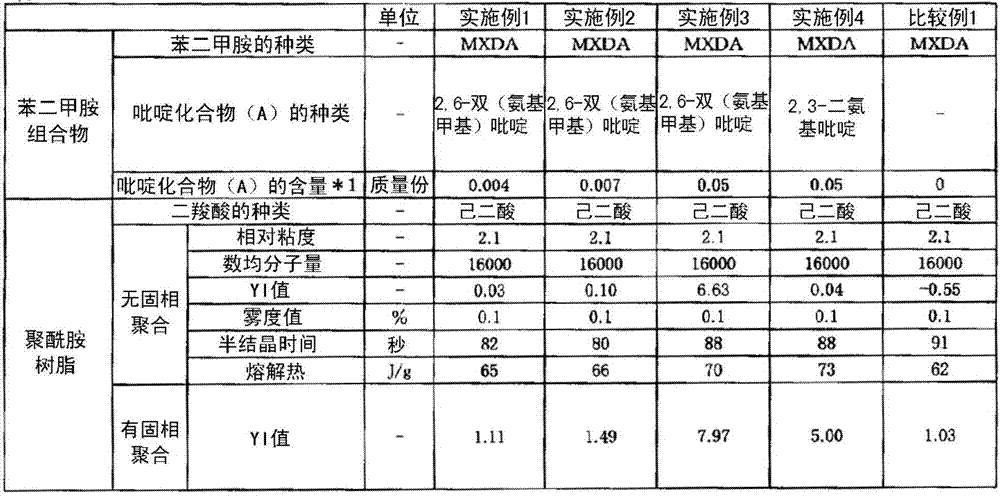

Embodiment 1

[0126] (Preparation of xylylenediamine composition)

[0127] A xylylenediamine composition was prepared so that the content of 2,6-bis(aminomethyl)pyridine would be 0.004 parts by mass relative to 100 parts by mass of m-xylylenediamine.

[0128] (Manufacture of polyamide resin)

[0129] 10 kg (68.43 mol) of adipic acid (manufactured by Rhodia Co., Ltd.) was put into a reaction vessel equipped with a stirrer, partial condenser, total condenser, thermometer, dropping funnel, nitrogen introduction pipe, and strand die, and nitrogen replacement was fully carried out. Afterwards, the system was further heated and melted to 170° C. while stirring under a small amount of nitrogen gas flow. Add 9.273 kg of the xylylenediamine composition obtained as described above (containing 68.08 mol of m-xylylenediamine) dropwise into the molten adipic acid while stirring, and discharge the generated condensation water out of the system , while continuously raising the internal temperature to 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com