Three-stage mixing device with hydrodynamic self-control

A three-stage mixing and fluid mechanics technology, applied in mixers, transportation and packaging, chemical instruments and methods, etc., can solve problems such as unfavorable technological transformation of small and medium-sized enterprises, inconvenient adjustment of production load, and increase in investment costs of production lines. The effect of saving equipment investment and operating costs, scientific design, and low operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

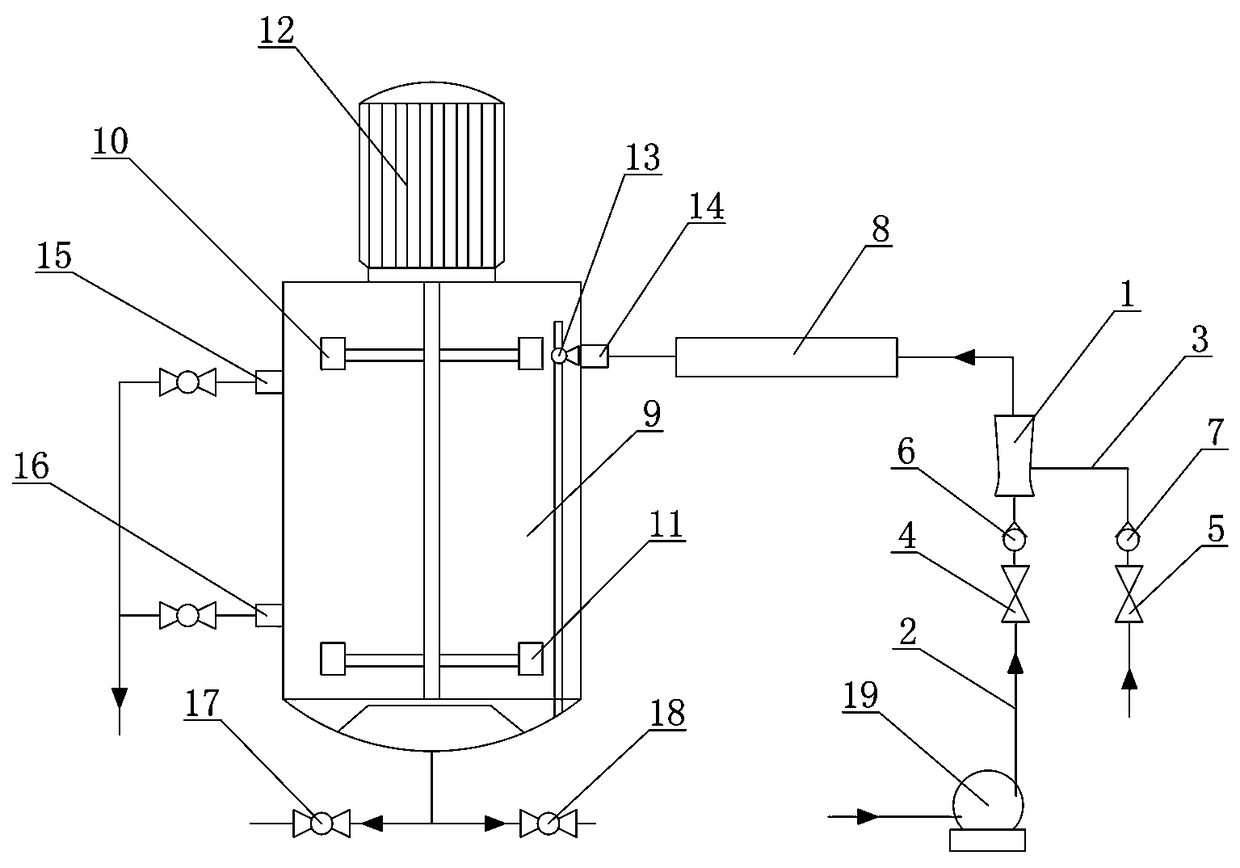

[0025] Such as figure 1 Shown, a kind of hydrodynamic self-controlled three-stage mixing device, comprises the three-stage mixing structure connected in sequence, one-stage mixing structure comprises Venturi mixer 1, the main road feed end 2 of described Venturi mixer 1 and auxiliary road The feed end 3 is equipped with a flow regulating valve a4, a flow regulating valve b5, a flow meter a6 and a flow meter b7, and the auxiliary material inlet of the Venturi mixer 1 is opened in the Venturi mixer 1 venturi tube of the contraction segment. The secondary mixing structure includes a static mixer 8 communicating with the discharge port of the Venturi mixer, and the tertiary mixing structure includes a stirring tank 9 communicating with the discharge port of the static mixer 8, located at the stirring The two-layer stirring paddle in the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com