A rapid coating coating line and coating process for rod-shaped utensils

A coating line and coating device technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of energy waste, low yield, etc., to reduce costs, increase diffuse reflection, The effect of supplementing light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the content of the present invention more clearly and completely, the concept of the present invention will be described below in conjunction with specific embodiments.

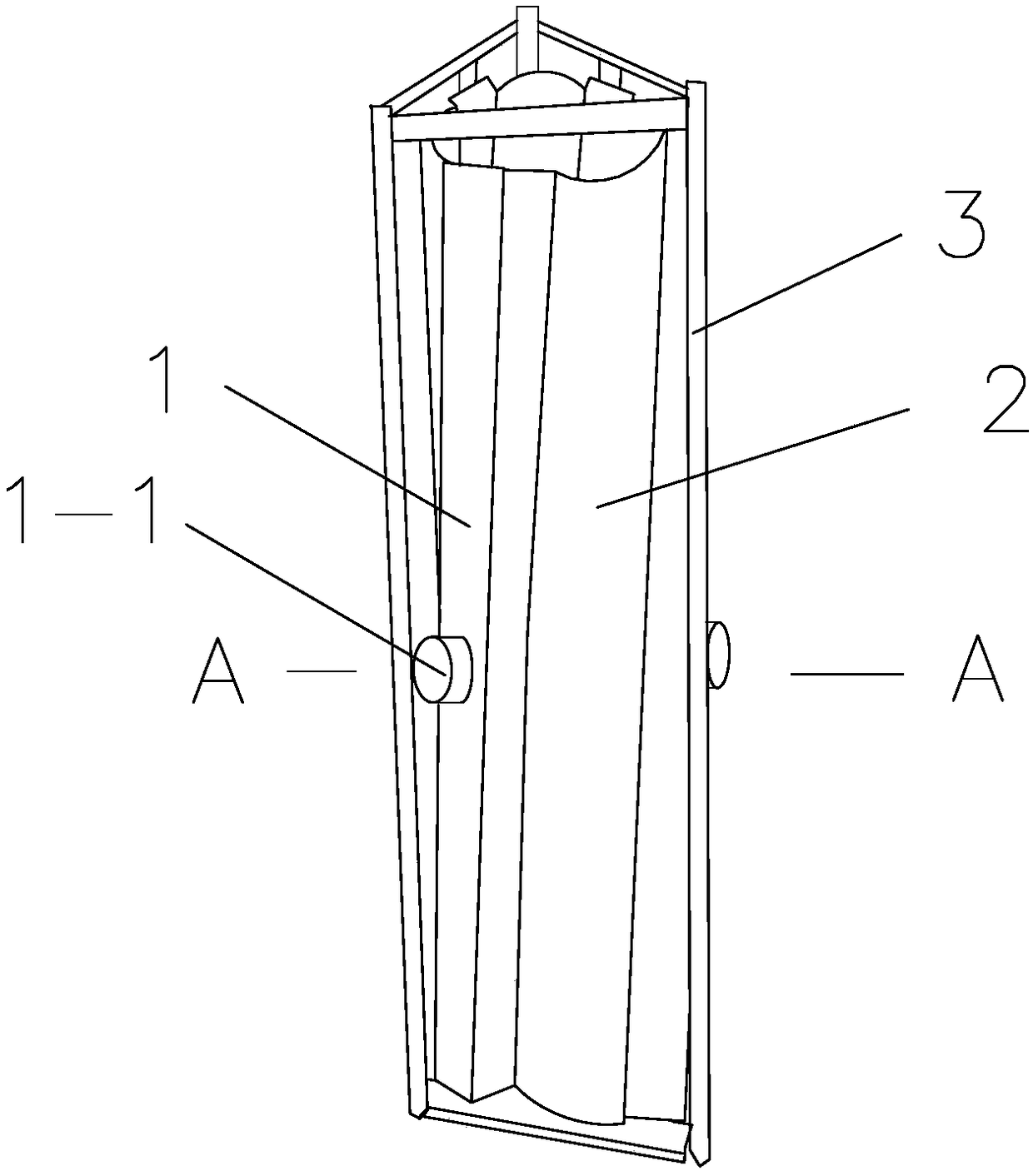

[0025] Such as Figure 1-3 As shown, a rapid coating and coating line for rod-shaped utensils includes a coating and varnishing device, and a curing device whose inlet is connected to the outlet of the coating and varnishing device.

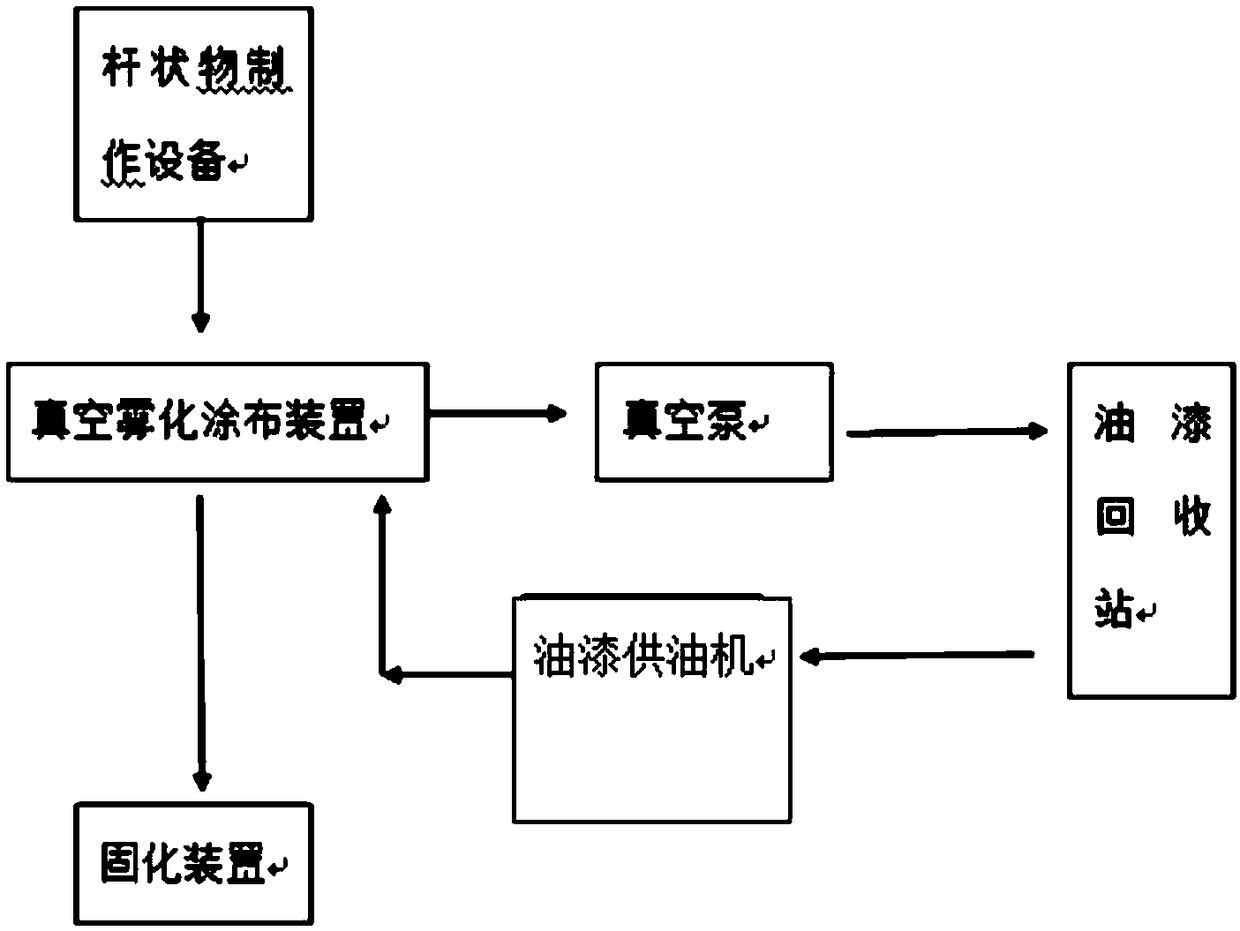

[0026] The coating and painting device includes a vacuum atomization coating device connected to the discharge port of the rod-shaped object making equipment, and also includes a paint recycling station connected by a vacuum pump and a vacuum atomization coating device. The paint in the recycling station is liquefied and passed through The paint feeder is transferred back to the vacuum atomization coating device.

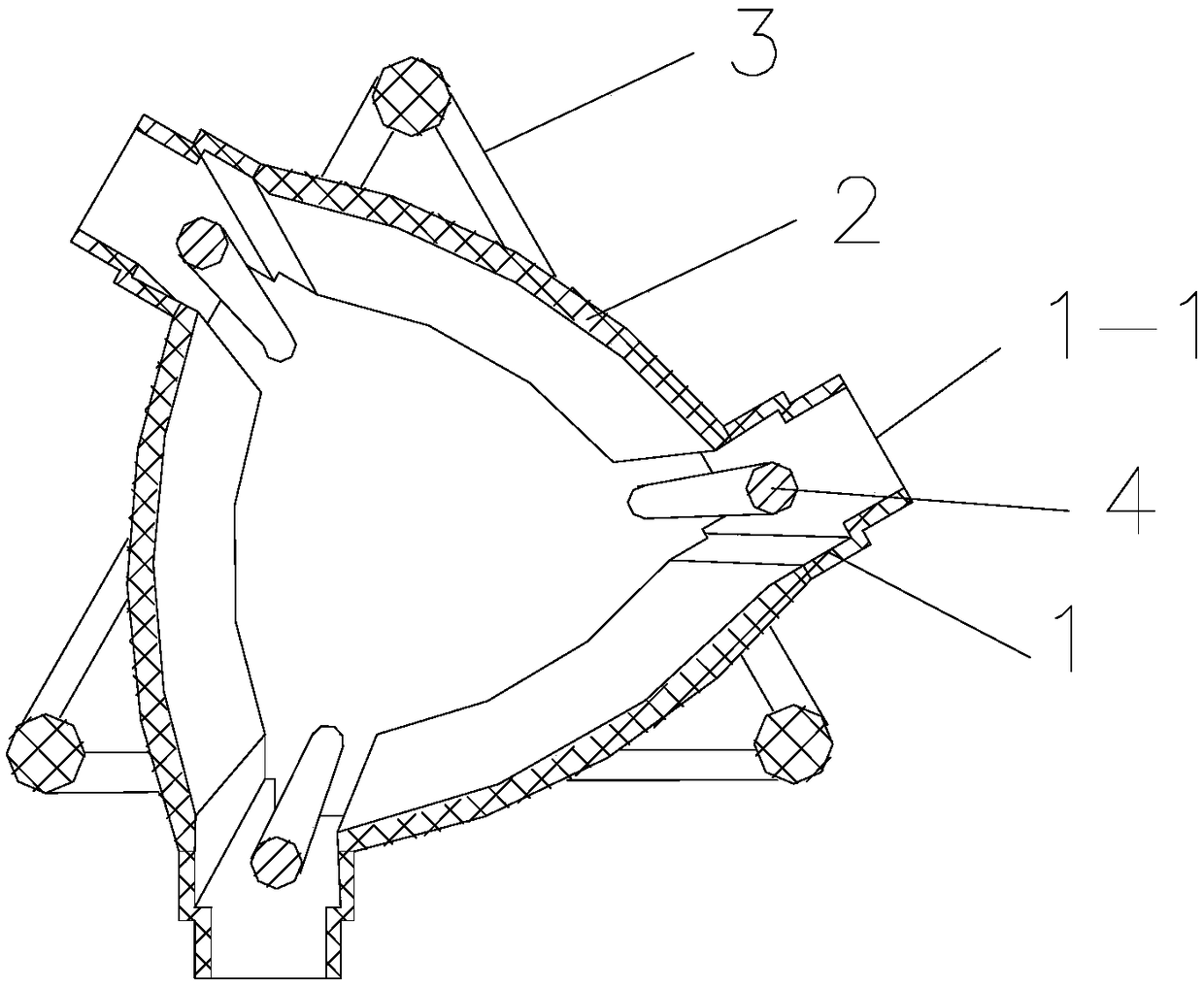

[0027] The curing device includes three light sources and a reflector. The reflector includes three lamp holders 1 mounted with lamp tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com