Improved wind turbine for production of electrical power with multiple-blade vanes and horizontal shaft supported at the ends

A technology of wind turbines and transverse shafts, applied in the direction of wind turbines, wind turbines, engines, etc. at right angles to the wind direction, can solve the problems of large-scale power generation facilities occupying a large area and occupying a large area, so as to achieve effective use and effective localization and natural resource effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

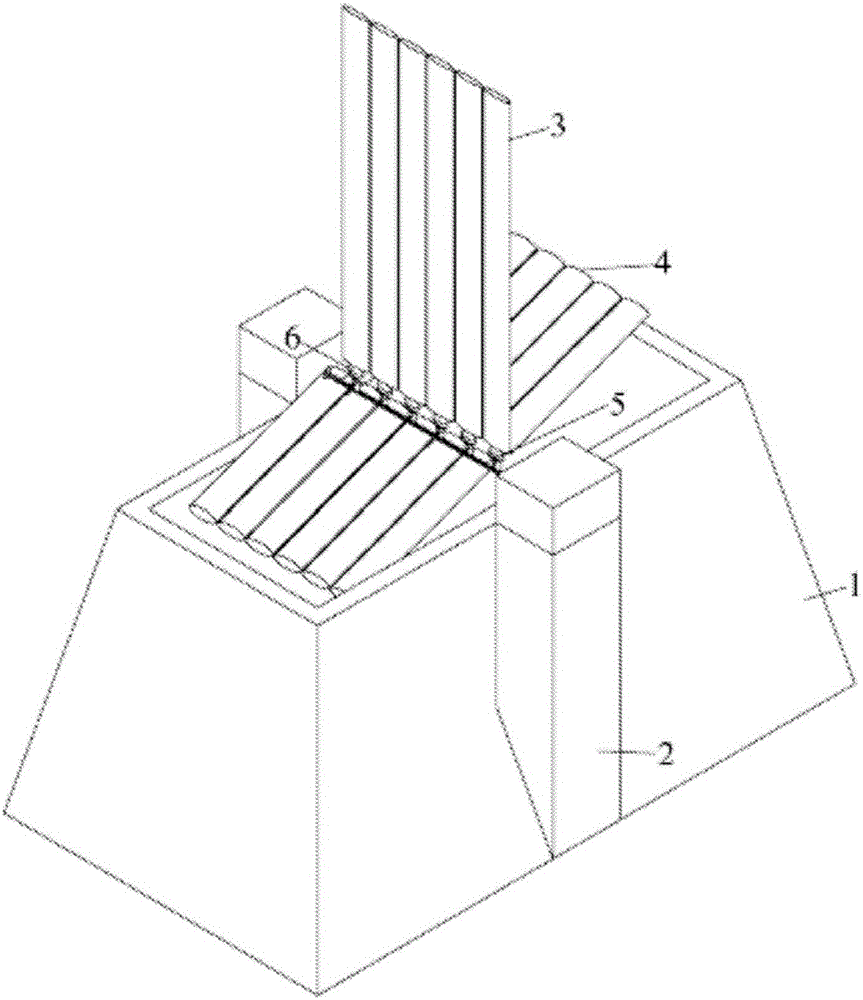

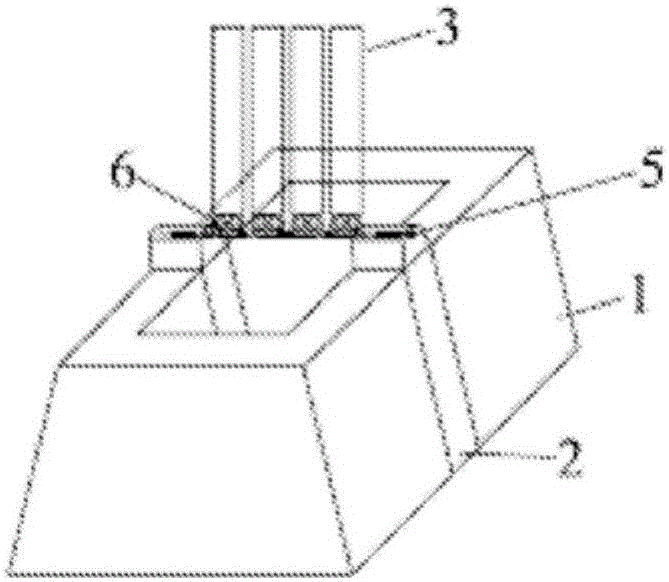

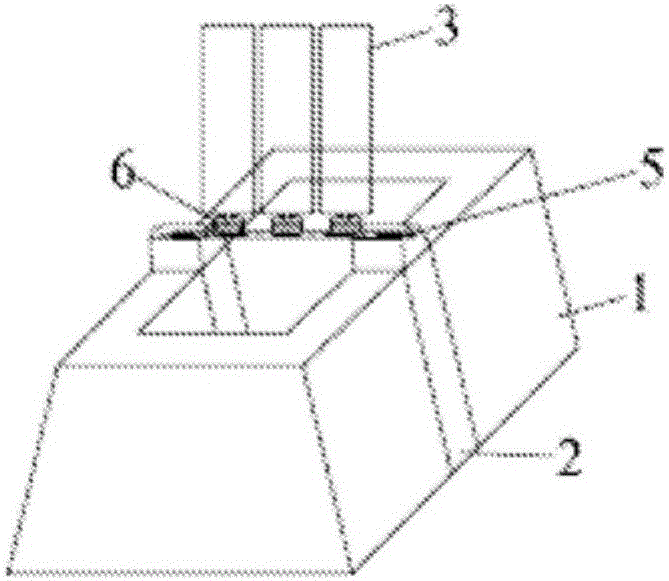

[0023] Such as figure 1 , 2.1 As shown in and 3, in a preferred embodiment of the present invention, the wind turbine has four flat plates 4, each flat plate is made of four parallel blades, and one end of each blade is connected to the horizontal axis 5 of the wind turbine rotation, and the horizontal axis The two ends of 5 are supported on two opposite sides of the conical frustum shell 1, and all sides of the conical frustum are closed. The blades 3 are arranged on a plane formed by a plurality of flat plates 4 symmetrically arranged around the transverse axis 5 of the wind turbine, each flat plate 4 has several blades 3 parallel to each other, and each blade 3 can pass through a double transmission device 6 , 7 are adjusted individually by rotating about the respective longitudinal blade axis which is perpendicular to the transverse axis 5 of the wind turbine. The number, length and size of the plates 4 and blades 3 depend on the wind energy to be generated.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com