Reel housing for connection line

A technology for connecting wires and reels, which is applied in the field of reel casings, can solve problems such as reel falling off, and achieve effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

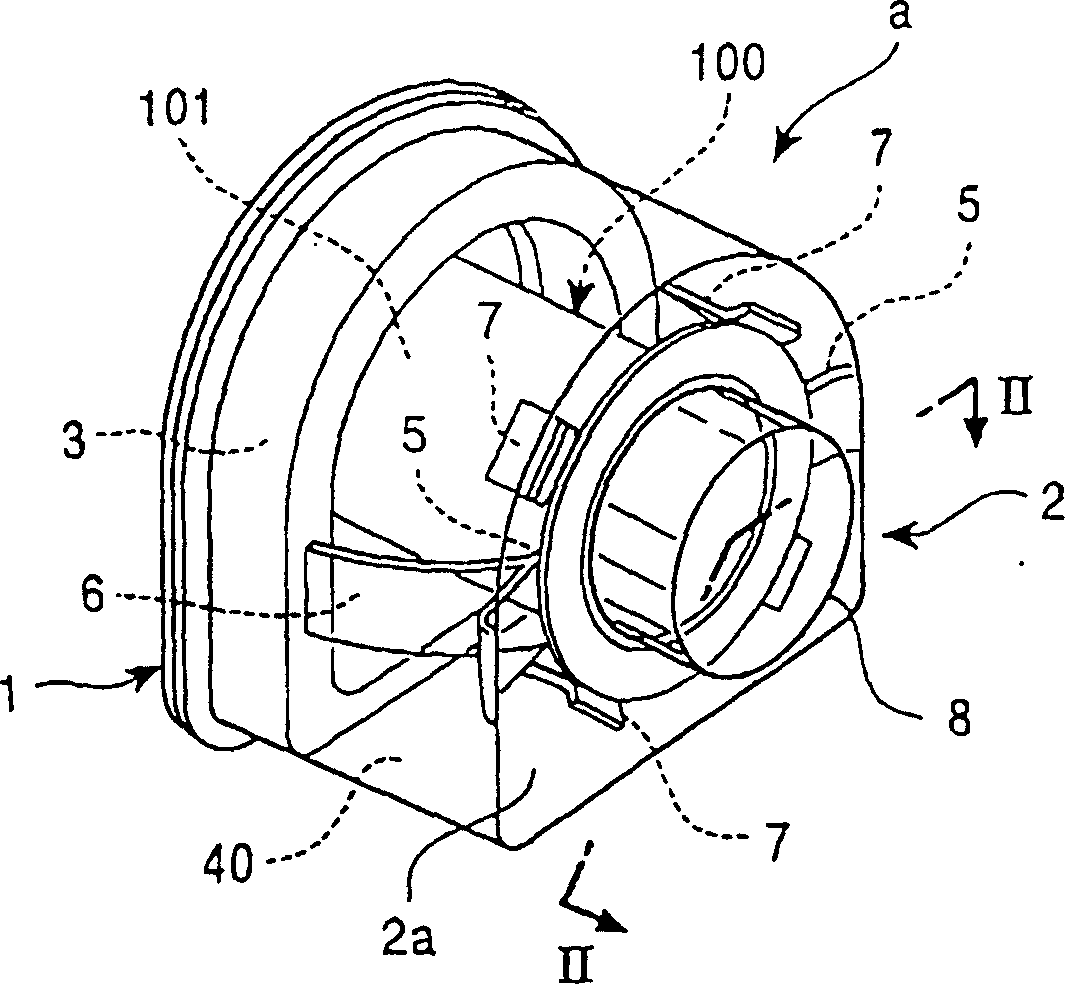

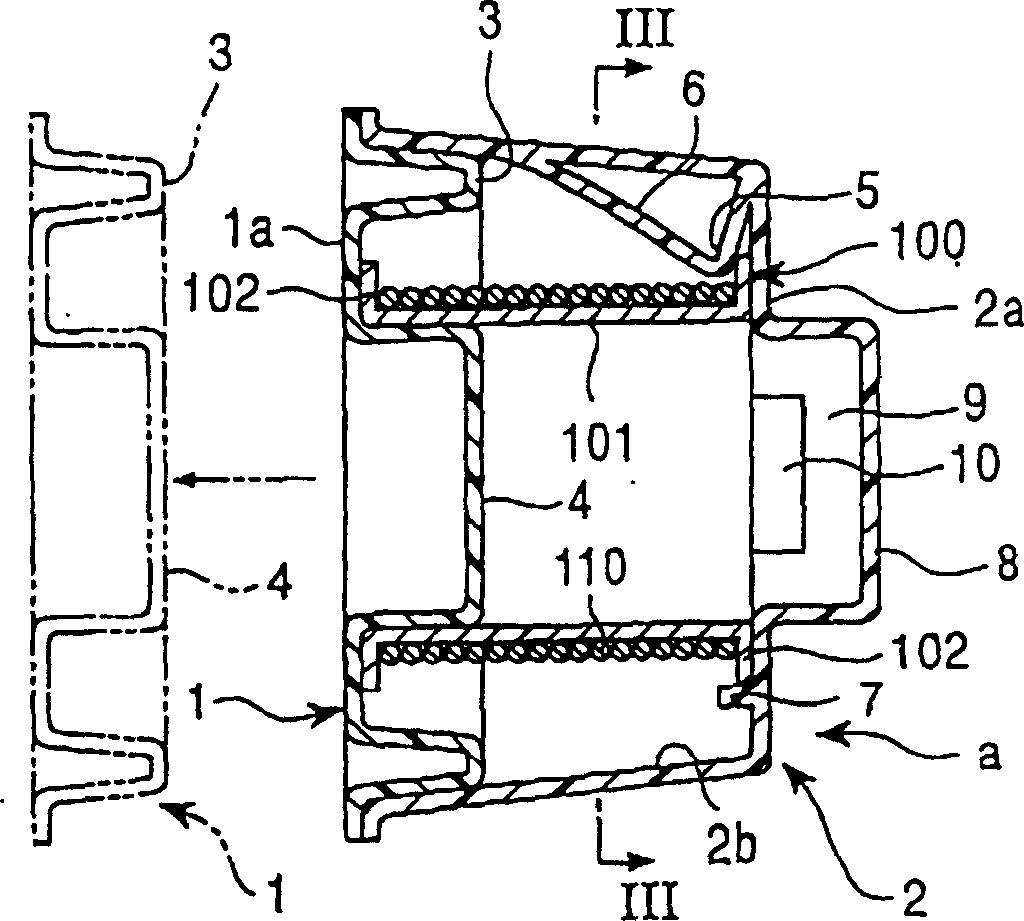

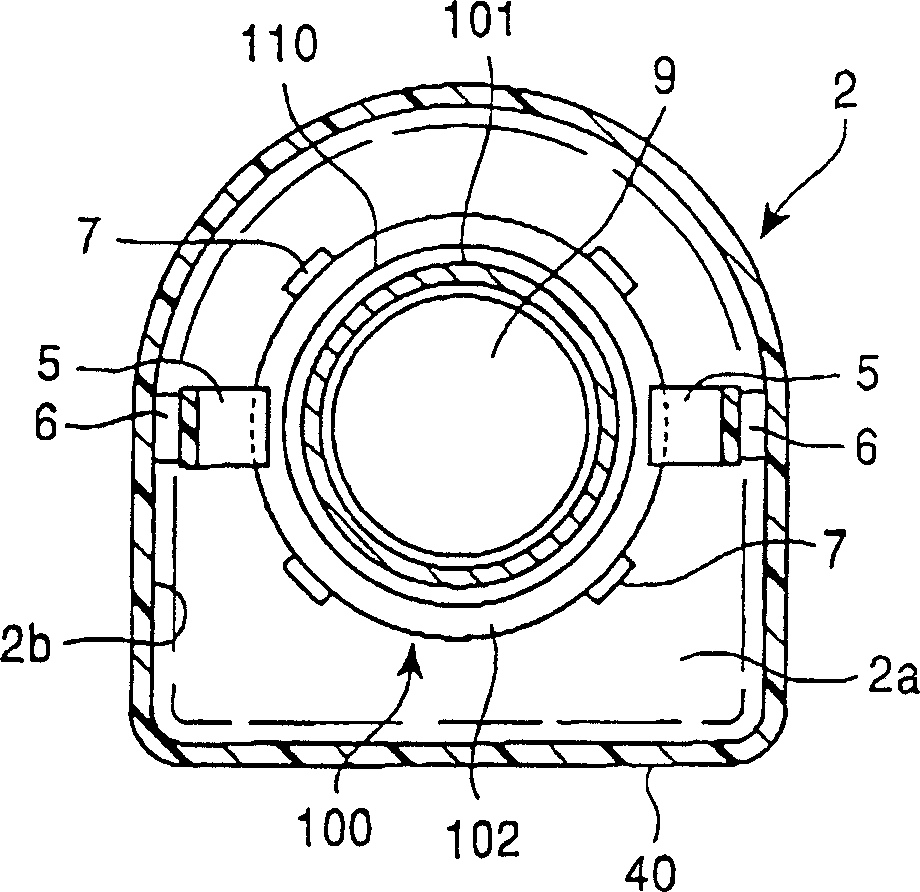

[0050] Embodiment 1: refer to figure 1 -4

[0051] figure 1 In -4, a is a reel cover, 100 is a reel, 110 is an electric wire, 200 is a reel holder of a wire bonding device, and 300 is a reel locking device attached to the holder.

[0052] The reel 100 has a structure commonly used in this technical field, and is provided with a cylindrical body 101 around which an electric wire 110 is wound, and left and right flanges 102, 102 provided on opening edges at both ends of the reel 100 .

[0053] The reel housing a is composed of a base plate 1 and a cover body 2 that are fitted together. The base plate 1 and the cover body 2 are made of materials such as plastics, and are elastically deformable by vacuum forming. The electric wire reel 100 is integrally formed by the top-covering fitting cover 2 .

[0054] The outer peripheral edge of the base plate 1 is protruded with an outer peripheral bulge 3 that can be fitted with the cover body 2, and the central part of the side wall 1a...

Embodiment 2

[0069] Embodiment 2: refer to Figure 5-1 0

[0070] Figure 5-1 The reel cover a' shown in 0 is composed of a base plate 1' and a cover 2' that are fitted together. The roll 100 inside the cover 2' is instead held by the base plate 1'.

[0071] In the figure, the components common to Embodiment 1 are represented by the same symbols as those of Embodiment 1. These common components will not be described repeatedly, and only the parts different from Embodiment 1 will be described as follows.

[0072] On the surface (i.e., the outer surface) 1b on the outer side of the housing corresponding to the side wall 1a of the base plate 1', there are a plurality of places that can be elastically engaged with the outer periphery of the flange 102 for maintaining the engagement of the flange 102. Sheet 11.

[0073] These engaging pieces 11 are mounted on a plurality of places on the outer surface 1b of the base plate 1 ′, and the front end of the mounting portion 12 is bent in a roughl...

Embodiment 3

[0087] Embodiment 3: Refer to Figures 11-17

[0088] The reel case a" shown in FIGS. 11-17 is composed of the substrate 3 and the cover 4 which are fitted together as shown in FIGS. 11-13, and accommodates the reel 2 with the electric wire 1 wound therein.

[0089] The drum 2 has flanges 2b, 2c at both ends. The diameter of the flanges 2b, 2c is in the range of 58.5-80mm.

[0090] The reel case a" is composed of a base plate 3 and a cover body 4 which are fitted together. The base plate 3 and the cover body 4 are made of materials such as plastics and are elastically deformable by vacuum forming. After holding the spool 2 wound with the electric wire, the cover body 4 is fitted in such a way as to cover the side to make it integral.

[0091] The outer peripheral portion of the base plate 3 is provided with an outer peripheral bulge 5 that can be fitted with the opening edge 4a of the cover body 4, and a central portion surrounded by the outer peripheral bulge 5 is formed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com