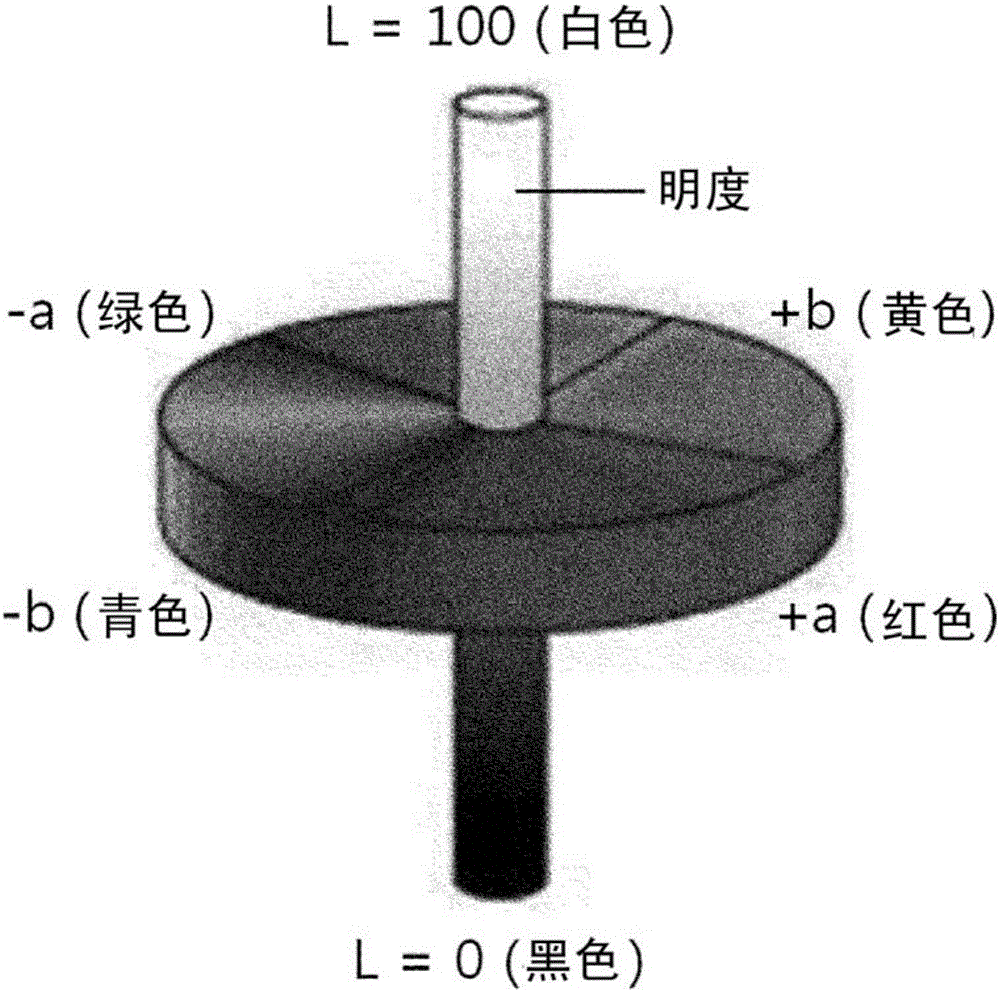

Color-treated base material and base material color treatment method therefor

A color treatment and base material technology, applied in the direction of metal material coating process, etc., can solve the problems of difficult to achieve metal texture, difficult to display various colors, etc., to achieve the effect of improved homogeneity and corrosion resistance, and effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] A 1 cm x 1 cm x 0.4 T test piece containing magnesium was dipped in an alkaline cleaning solution for degreasing, and the degreased test piece was immersed in a 10% by weight NaOH solution at 100° C. for 40 minutes. Then, the test piece was rinsed with distilled water and dried in a drying oven to prepare a color-treated test piece.

Embodiment 2

[0108] Instead of immersing the magnesium test piece in a 100° C., 10% by weight NaOH solution for 40 minutes in the above-mentioned Example 1, but immersing it for 30 minutes, it was carried out in the same manner as in the above-mentioned Example 1, Thus, a test piece chromogenically treated to yellow was prepared.

Embodiment 3

[0110] Instead of immersing the magnesium test piece in a 100°C, 10% by weight NaOH solution for 40 minutes in the above-mentioned Example 1, it was immersed for 55 minutes. Thus, a test piece chromogenically treated to violet was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com