Outer gear clamping device with convenient and fast clamping mechanism

A technology of clamping mechanism and clamping device, which is applied in the direction of grinding workpiece brackets, etc., can solve the problems of high cost, inconvenient use, and tiredness of workers after long-term use, so as to reduce labor intensity, ensure production pass rate, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

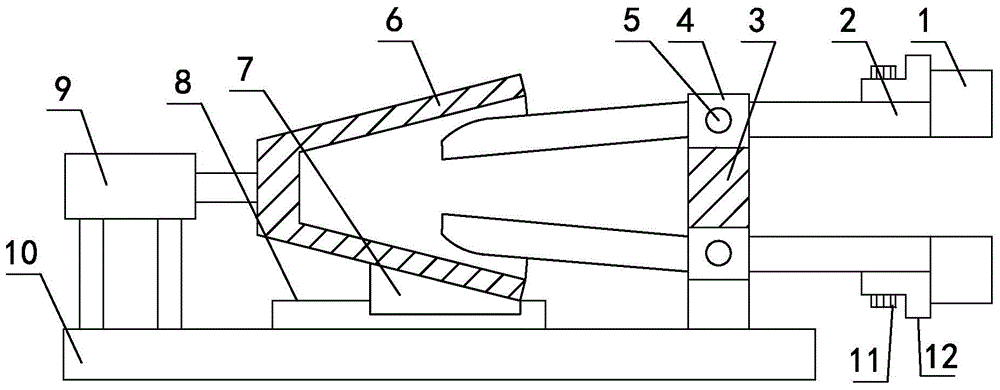

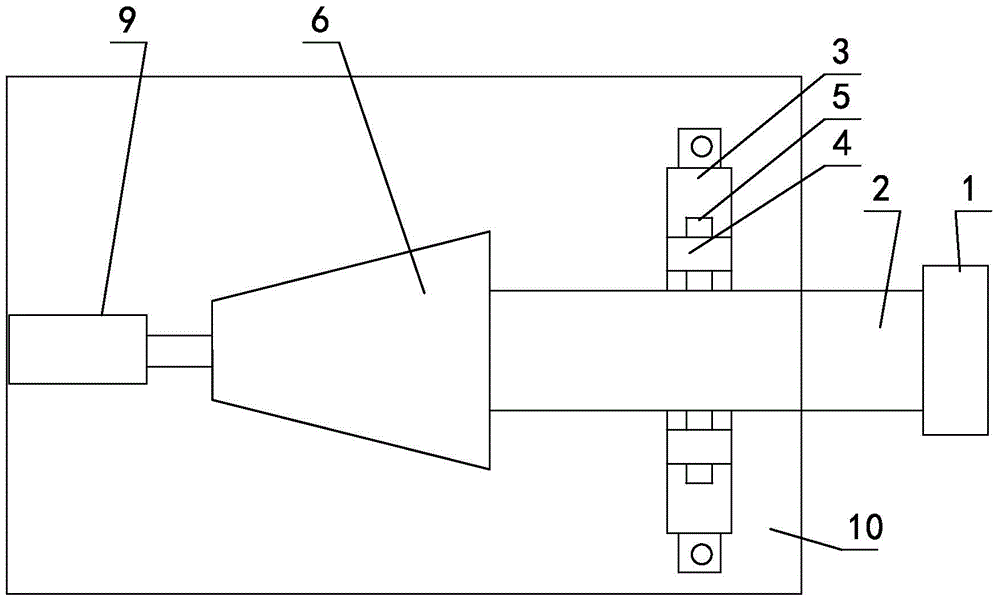

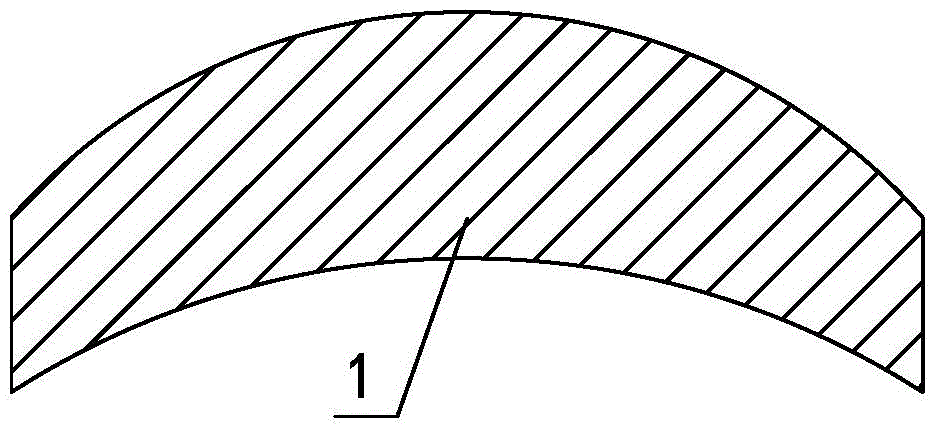

[0018] like figure 1 , figure 2 , image 3 As shown in the figure, the external gear clamping device with a convenient clamping mechanism includes a lever mounting seat 3, a collet and a clamping arm. The clamping arm is composed of an upper clamping arm 2 and a lower clamping arm that cooperate with each other. The collet 1 and the lower collet are composed, an upper hinge seat 4 is installed on the upper part of the lever mounting seat 3, the upper clamp arm 2 is laterally hinged on the upper hinge seat 4 through the upper pivot shaft 5, and the upper clamp is fixed on the right end of the upper clamp arm 2 Head 1; a lower hinge seat is installed at the lower part of the lever mounting seat 3, the lower clamp arm is laterally hinged on the lower hinge seat through the lower pivot shaft, the lower clamp head is fixed at the right end of the lower clamp arm, and the upper clamp arm 2 and the left side of the lower clamp arm are fixed A taper sleeve 6 is arranged horizontall...

Embodiment 2

[0022] Further changes are made on the basis of Example 1, and the taper of the tapered sleeve 6 is changed to 60 degrees; the length of the tapered sleeve 6 is changed to 800 mm. Others are the same as the first embodiment.

Embodiment 3

[0024] Further changes are made on the basis of the first embodiment, and the taper of the tapered sleeve 6 is changed to 50 degrees; the length of the tapered sleeve 6 is changed to 700 mm. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com