Liquid damping type braking system

A brake system and liquid damping technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., to achieve the effects of convenient use and maintenance, low manufacturing cost, safe and reliable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

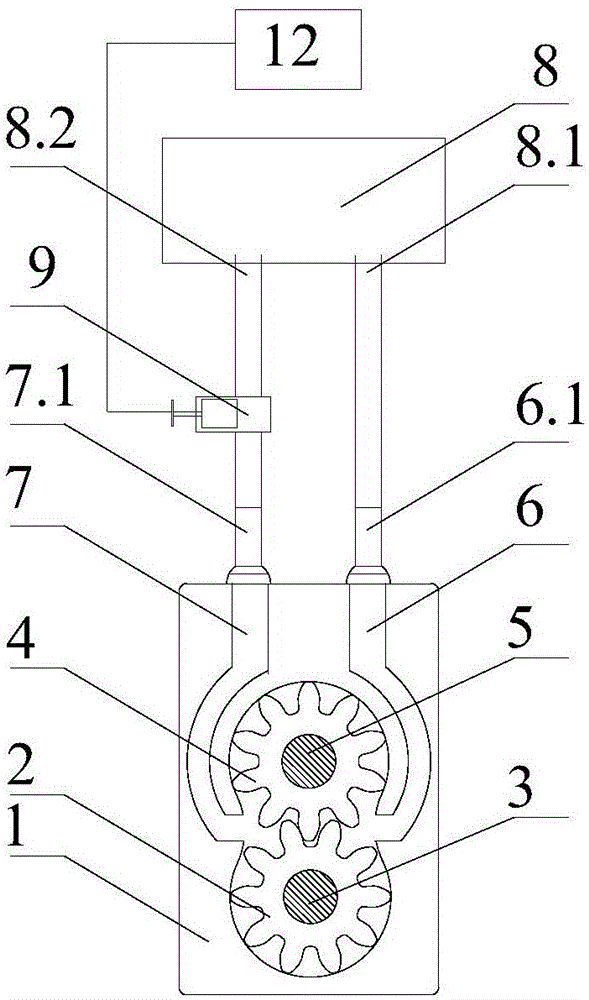

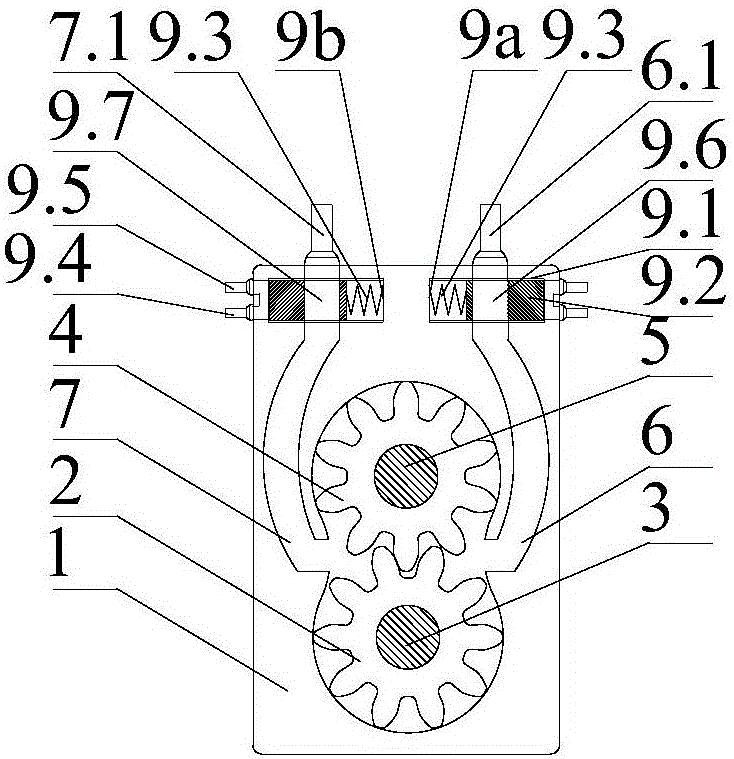

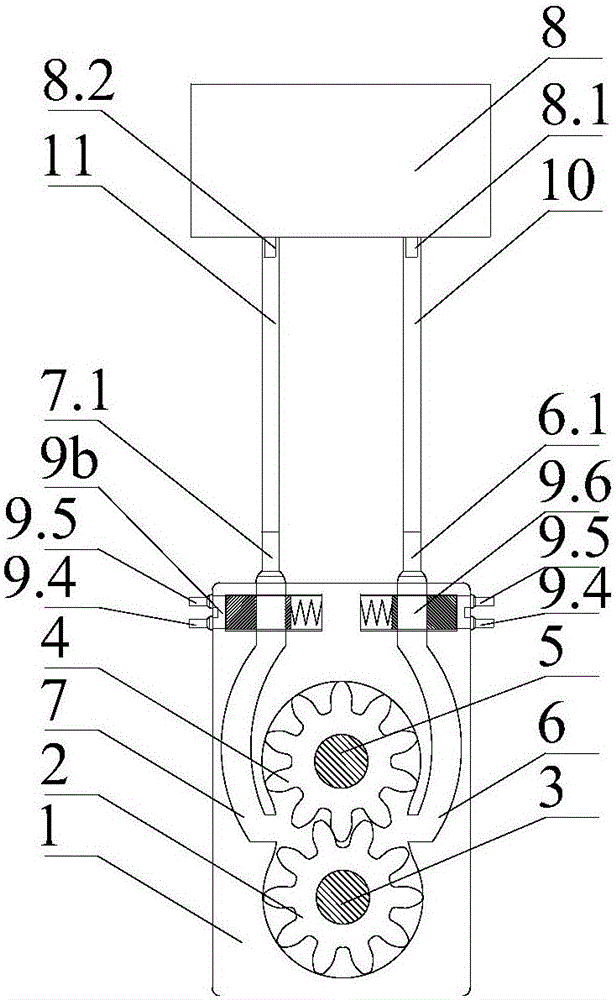

[0024] Such as figure 1 As shown, an external meshing liquid damping braking system of the present invention includes a damping part and a braking control part, and is characterized in that the damping part includes a sealed gear box 1 fixedly coupled with the equipment body, which is arranged on the At least one pair of relatively externally meshed gears in the gearbox 1 that match the inner cavity of the gearbox, wherein the driven gear 2 is installed in the gearbox 1 through the driven wheel shaft 3, and the driving wheel shaft 5 of the driving gear 4 is the brake shaft Extending out of the gear box to connect with the external drive shaft or the external drive shaft, the gear boxes on both sides of the relatively externally meshed gears are respectively provided with flow pipes 6, 7, and the two flow pipes 6, 7 are provided on the gear box body The outlets 6.1, 7.1 are connected to the two interfaces 8.1, 8.2 of the brake fluid storage tank 8 to form a brake fluid sealed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com